Ultraviolet curing chromatic wall decoration board and preparation method thereof

A technology of wall decoration and ultraviolet light, which is applied in decorative arts, devices for coating liquid on surfaces, and surface pretreatment, etc. It can solve the problems of high investment in electron beam curing equipment, high equipment operating costs, and large site occupation. , to achieve good decorative and protective effects, good environmental protection, and full paint film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0084] Example 1. Gray wall trim panels

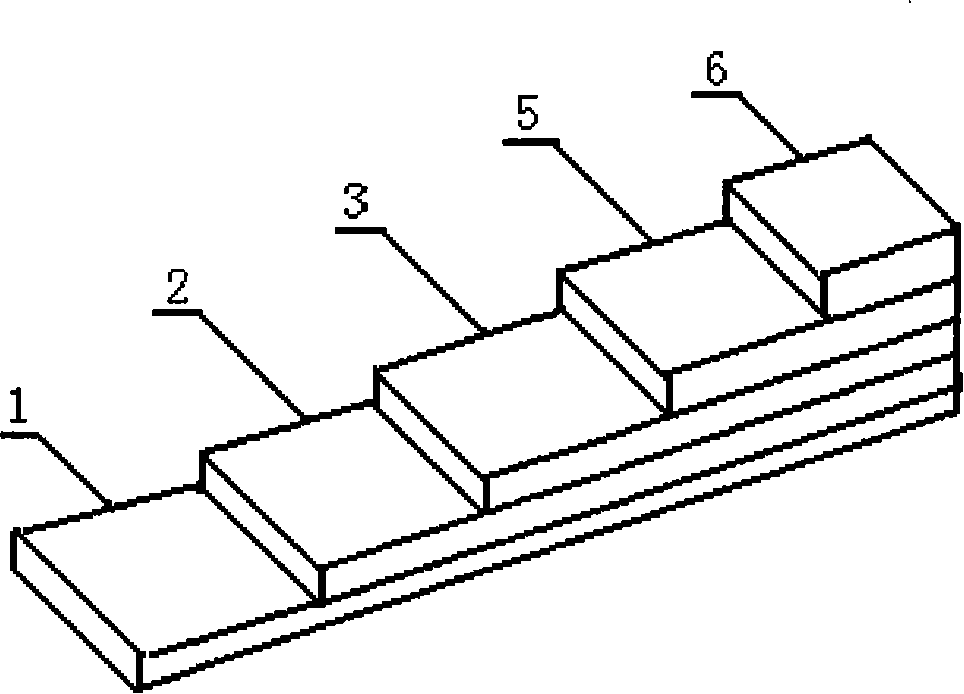

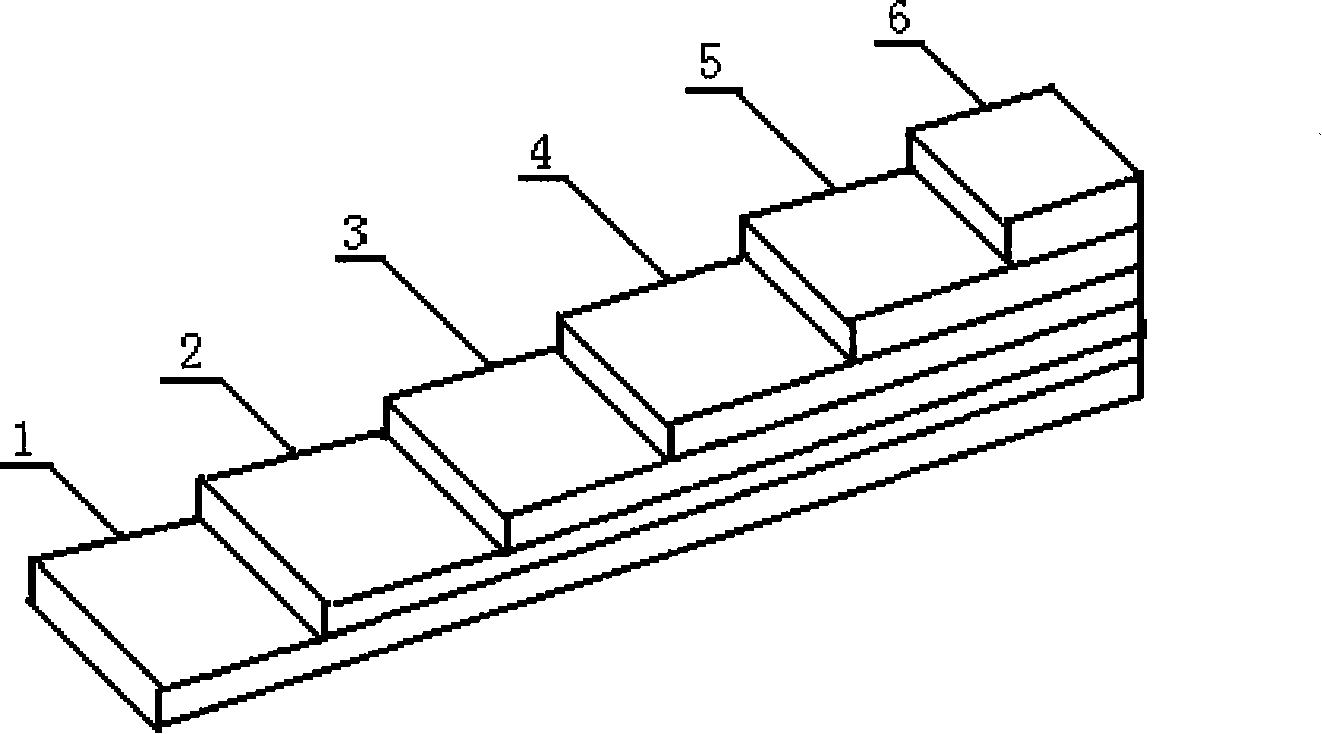

[0085] See figure 1 . First, sand the base 1 of the wall decoration board to make it smooth and remove the dust on the surface, then roll-coat a layer of UV-curable putty 2 with a thickness of 50um on the surface of the base of the wall decoration board, and put it into a place where two 9.6kw ultraviolet lamps (high pressure) are installed. Mercury lamp), a light curing machine with a transmission speed of 20 m / min. After curing, use a sander to sand and remove the dust on the surface, and then roll-coat a layer of 20um thick putty on the surface of the sanded UV-cured putty. UV-curing sealing clear primer 3, enter and be equipped with 2 13kw ultraviolet lamps (high-pressure mercury lamp), the light curing machine that transmission speed is 20 meters / min, after curing, sand light and remove the dust on the surface with a sander, Then roll-coat a layer of UV-curable gray topcoat 5 with a thickness of 30um and a gloss of 10-100 degree...

Embodiment 2

[0089] Example 2. Silver-gray wall decoration board

[0090] See figure 1 . First sand the base 1 of the wall decoration board to make it smooth and remove the dust on the surface, then roll-coat a layer of UV-curable putty 2 with a thickness of 30um on the surface of the base of the wall decoration board, and put it into the place where two 11kw ultraviolet lamps (high pressure mercury light), a light curing machine with a transmission speed of 10 m / min, after curing, sand with a sander and remove the dust on the surface, and then roll-coat a layer of UV light curing putty with a thickness of 50um on the surface of the sanded UV putty Light-curing sealing clear primer 3, enters and is equipped with 2 11kw ultraviolet lamps (high-pressure mercury lamp), and the light-curing machine that transmission speed is 10 meters / minute, after curing, sand light and remove the dust on the surface with a sander, and then Spray a layer of UV-curable silver-gray topcoat 5 with a thickness ...

Embodiment 3

[0094] Example 3. Red pearlescent wall decoration board

[0095] See figure 1 . First sand the base 1 of the wall decoration board to make it smooth and remove the dust on the surface, then roll-coat a layer of UV-curable putty 2 with a thickness of 80um on the surface of the base of the wall decoration board, and put it into the place where two 13kw ultraviolet lamps (high pressure mercury light), a light curing machine with a transmission speed of 30 m / min, after curing, sand with a sander and remove the dust on the surface, and then roll-coat a layer of 30um UV putty on the surface of the sanded UV curable putty Light-curing sealing clear primer 3, enters and is equipped with 2 13kw ultraviolet lamps (high-pressure mercury lamp), the light-curing machine that transmission speed is 30 meters / min, after curing, sand light and remove the dust on the surface with a sander, and then Spray a layer of UV-curable red pearlescent topcoat 5 with a thickness of 40um and a gloss of 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| luster | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com