Separation and purification method of trehalose

A technology for separation and purification of trehalose, applied in the field of sugar engineering, which can solve the problems of high cost of separation, complex process, inability to separate maltose and trehalose, and achieve the effects of environmental friendliness, low labor intensity and small production site

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The calcium-ion type polymer vinyl system gel type strong acid cation exchange resin described in embodiment 1 is purchased from Finex Oy company;

Embodiment 2

[0034] The calcium-ion type polymer vinyl system gel type strong acid cation exchange resin described in embodiment 2 is purchased from purolite company;

Embodiment 3

[0035] The calcium ion type polymer vinyl system gel type strong acid cation exchange resin described in Example 3 was purchased from Shandong Lukang Like Pharmaceutical Chemical Co., Ltd.;

[0036] The 001×7 cationic resin was purchased from Purolite Company; the 201×7 anionic resin was purchased from Purolite Company.

[0037] The trehalase reaction liquid in the examples was obtained by crushing and filtering the fermented liquid prepared by the method in Chinese patent document CN101831474A (application number 201010137964.2) with a high-pressure cell disruptor. The sugar components in the trehalase reaction liquid are maltose, glucose and trehalose.

[0038] Glucoamylase was purchased from Novozymes (China) Biotechnology Co., Ltd.

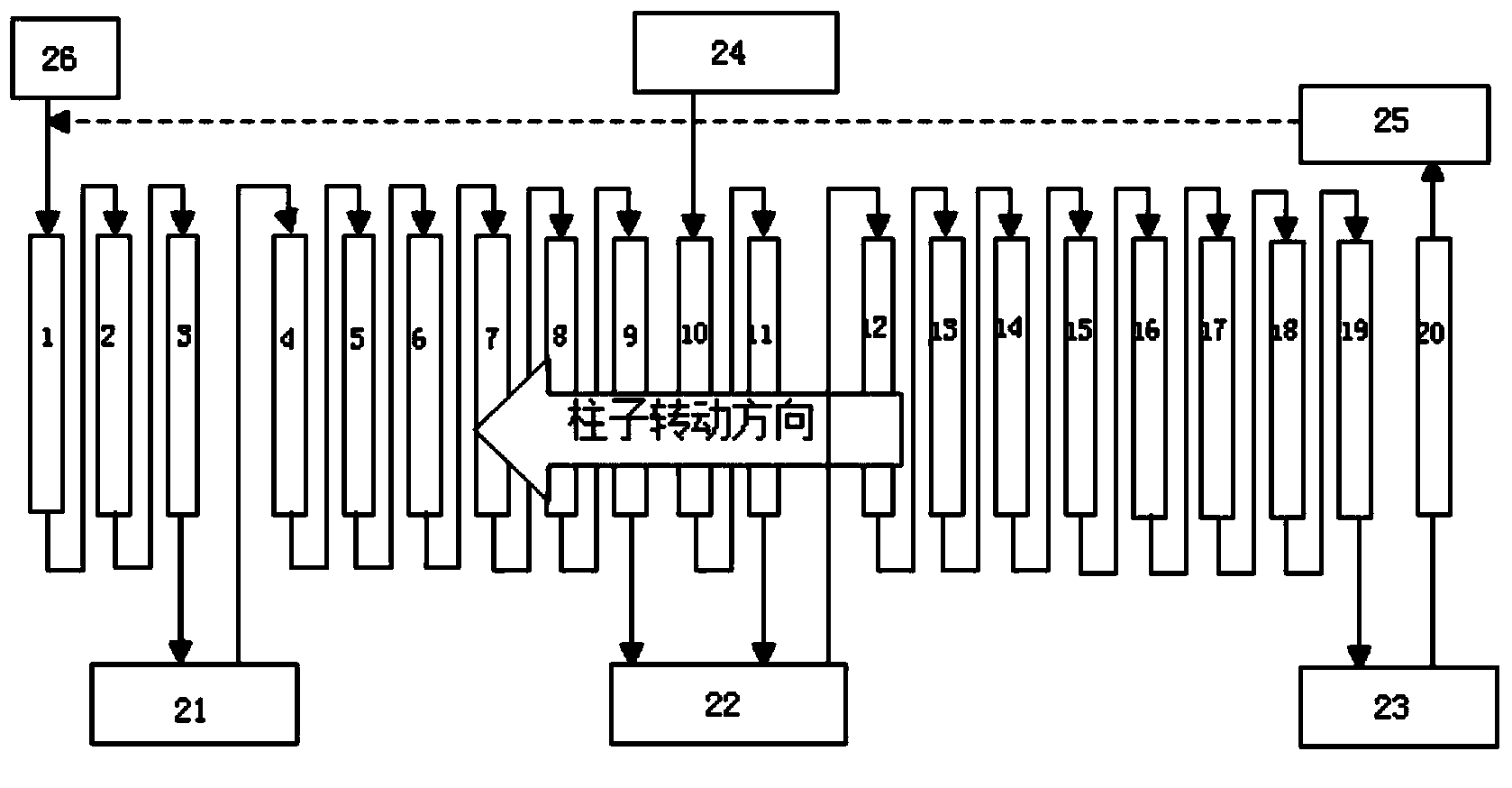

[0039] separation equipment

[0040]The simulated moving bed consists of five separation areas composed of 20 rotating chromatographic columns. Area Ⅰ is composed of chromatographic columns No. 1 to 3 connected in series, area II is composed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| mass | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com