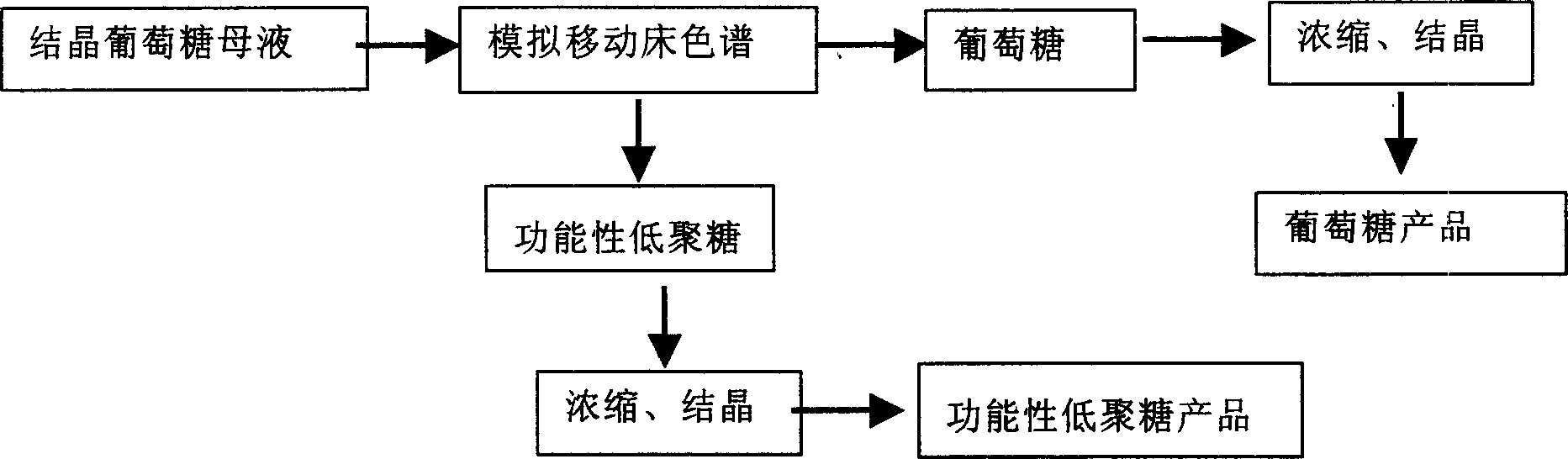

Method for extracting high purity glucose and functional oligose from crystalline glucose mother liquid

A technology of functional oligosaccharides and crystallized glucose, which is applied in the direction of glucose production, sugar production, sugar production, etc., can solve the problems of oligosaccharides not being utilized and recycling, and achieve small production sites and low production costs , The effect of high resin utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

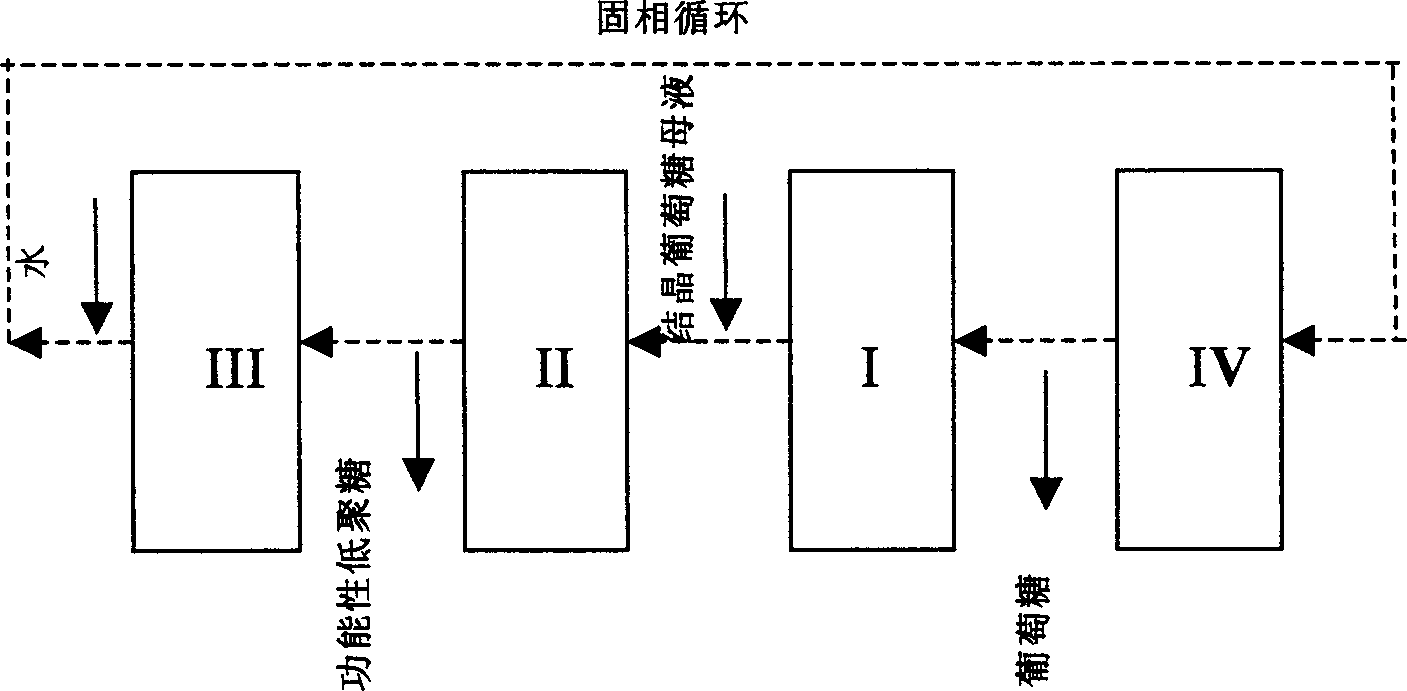

Method used

Image

Examples

Embodiment 1

[0025] The feed liquid is crystallized glucose mother liquor, its concentration is about 64.6%, of which glucose content is 74.48%, mannose 5.17%, disaccharide 11.76%, trisaccharide 4.70%, tetrasaccharide and above 3.62%; in addition, fructose 0.27% , the mother liquor is passed through the simulated moving bed, and the operating conditions of the simulated moving bed are as follows: separation temperature 65°C, system pressure 1.1Mpa, feeding amount of feed liquid is 1L / h, feeding amount of eluting water is 3.5L / h, feeding Equilibrium was reached after 24 hours. The output obtained is as follows:

[0026] 1) Glucose part: the product sugar liquid concentration ~ 42%, wherein the glucose content is 95.8%.

[0027] 2) Functional oligosaccharides: the concentration of the product's sugar solution is ~9.5%, the content of polysaccharides is ~60%, and the content of glucose is 35.8%.

Embodiment 2

[0029] The feed liquid is crystallized glucose mother liquor, its concentration is about 48.3%; the content of glucose is 78.1%, disaccharide 12.7%, trisaccharide and above 5.8%, fructose etc. 3.5%, this mother liquor is passed through the simulated moving bed, simulated moving bed operation The conditions are as follows: the separation temperature is 70°C, the system pressure is 1.1Mpa, the feeding amount of the feed liquid is 1L / h, the feeding amount of the eluting water is 3.5L / h, and the feed reaches equilibrium after 24 hours. The output is as follows:

[0030] 1) Glucose part: the concentration of the product sugar solution is ~27%, of which the glucose content is 97.1%,

[0031] 2) Functional oligosaccharides: product sugar solution concentration 5.3%, of which glucose 17.52%; maltose 21.60%; isomaltose 20.58%; maltotriose 4.07%; panose 16.11%; tetrasaccharides and above 20.00%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com