Surface automatic spray painting and drying device in steel structure

An automatic painting and drying device technology, which is applied to the surface coating liquid device, spraying device, coating, etc., can solve the problems of time-consuming and manpower, occupying production space, affecting production efficiency, etc., to improve production efficiency, The effect of high paint utilization rate and accelerated curing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

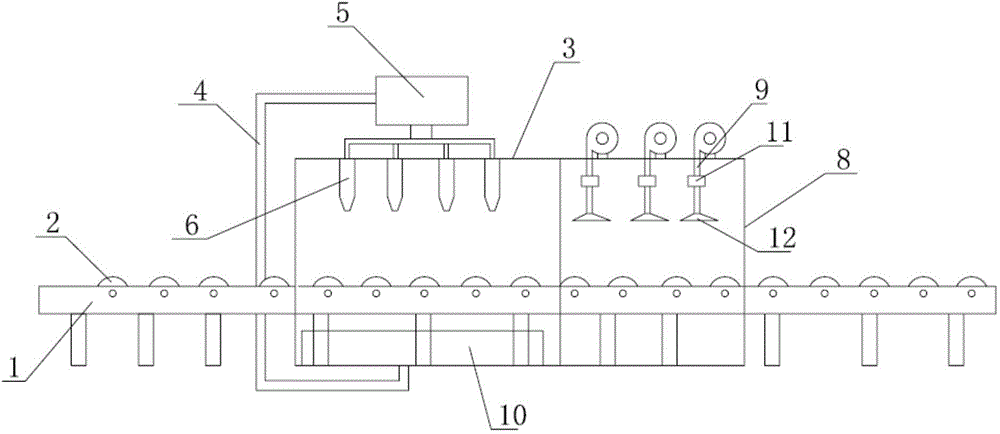

[0025] The steel that has been welded and surface-treated by the shot blasting machine is placed on the conveying platform 1, and is conveyed forward by the rolling of the roller shaft 2, and enters the paint spraying box 3, and the paint spray head 6 in the paint spraying box 3 sprays the paint into the paint storage box 5 The paint in it is sprayed on the surface of the steel structure to form a certain thickness of anti-rust paint layer on the surface of the steel structure.

[0026] After the paint is sprayed, the steel structure enters the surface drying box 8, and a plurality of blowing nozzles 9 blow out strong hot air downwards. The hot air is instantly heated by the heater 11, which can dry the paint on the surface of the steel structure in a short time.

[0027] The unnecessary paint sprayed in the paint spraying box 3 all falls into the paint collection box 10 and collects, and the collected paint is delivered to the paint storage box 5 by the pipeline 4 again for re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com