Durability traceless repair method for road and bridge concrete, color difference trimming putty and trimming material

A concrete and durable technology, applied in bridge maintenance, on-site coagulation pavement, roads, etc., can solve the problems of lack of overall coating, repair marks, color difference, etc., achieve low implementation cost, solve serious impact, The effect of excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

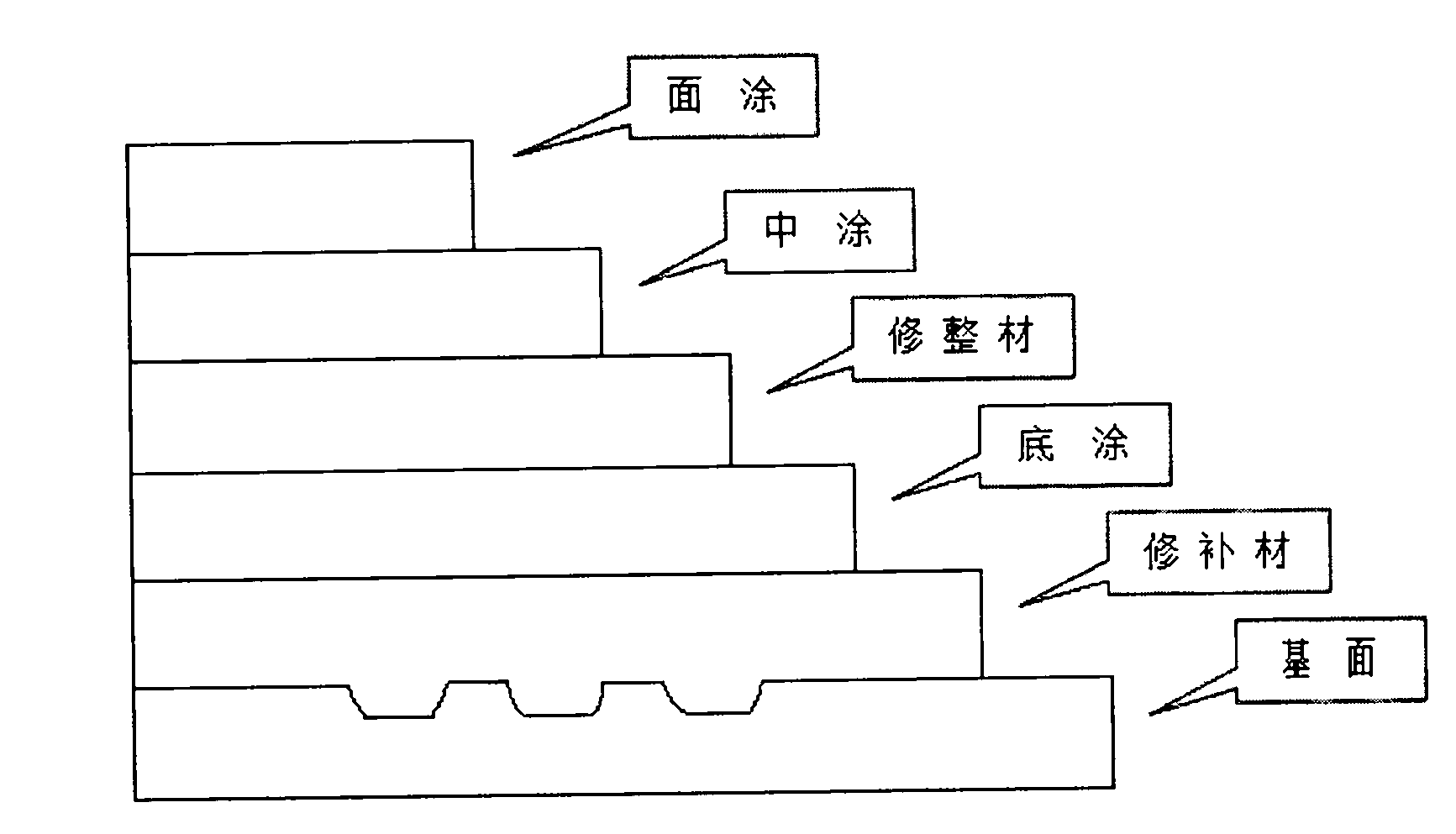

[0086] Concrete with light-colored surface defects, polymer fine sand mortar can use Huibang D-102C polymer modified mortar with high flexural strength, compressive strength and bonding strength to repair larger defects on the concrete surface, and the base surface Trim and smooth;

[0087] Color finishing is carried out with a color difference finishing putty which closely matches the color of the concrete structure.

[0088] This chromatic aberration repairing putty is as follows (mass parts, total amount is 100) for single-component main formula:

[0089] White Portland cement 25

[0090] Ordinary Portland cement 3

[0091] Mineral powder 5

[0092] Quartz sand (100 mesh) 35

[0093] Quartz sand (200 mesh) 30

[0094] Available in dispersible latex powder 1.6

[0095] Medium-effect superplasticizer 0.2

[0096] Defoamer 0.2.

[0097] Using water-based silane complex emulsion Wacker company As a primer, BS 43N can significantly reduce the surface tension in the are...

Embodiment 2

[0129] Concrete with dark surface defects, polymer fine sand mortar can use Huibang D-102C polymer modified mortar with high flexural strength, compressive strength and bonding strength to repair larger defects on the concrete surface, and the base surface Trim and smooth;

[0130] Color finishing is carried out with a color difference finishing putty which closely matches the color of the concrete structure.

[0131] This chromatic aberration repairing putty is as follows (mass parts, total amount is 100) for single-component main formula:

[0132] White Portland cement 0

[0133] Ordinary Portland cement 26

[0134] Mineral powder 7

[0135] Quartz sand (100 mesh) 33

[0136] Quartz sand (200 mesh) 30

[0137] Available in dispersible latex powder 1.5

[0138] Medium-effect superplasticizer 0.2

[0139] Defoamer 0.3.

[0140] The trimming material formula adopts the same material as in Example 1.

[0141] Using solvent-based silane complex emulsion Wacker BS 290 as ...

Embodiment 3

[0163] For concrete with light-colored surface defects, the polymer fine sand mortar can use Huibang D-102C polymer modified mortar with high flexural strength, compressive strength and bonding strength to repair larger defects on the concrete surface. Surface trimming and smoothing;

[0164] Color finishing is carried out with a color difference finishing putty which closely matches the color of the concrete structure.

[0165] This chromatic aberration repairing putty is as follows (mass parts, total amount is 100) for single-component main formula:

[0166] White Portland cement 12

[0167] Ordinary Portland cement 16

[0168] Mineral powder 5

[0169] Quartz sand (100 mesh) 35

[0170] Quartz sand (200 mesh) 30

[0171] Available in dispersible latex powder 1.6

[0172] Medium-effect superplasticizer 0.1

[0173] Defoamer 0.3.

[0174] The trimming material formula adopts the same material as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com