Ultraviolet light curing overlay film decorative board for wall and method for making same

A wall decoration, ultraviolet light technology, applied in decorative arts, processes for producing decorative surface effects, covering/lining, etc., can solve the problem of high investment in electron beam curing equipment, high equipment operating costs, and large site occupation area. problem, to achieve good decorative effect and protection effect, high production efficiency, good environmental protection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] Embodiment 1. Imitation marble wall decoration board

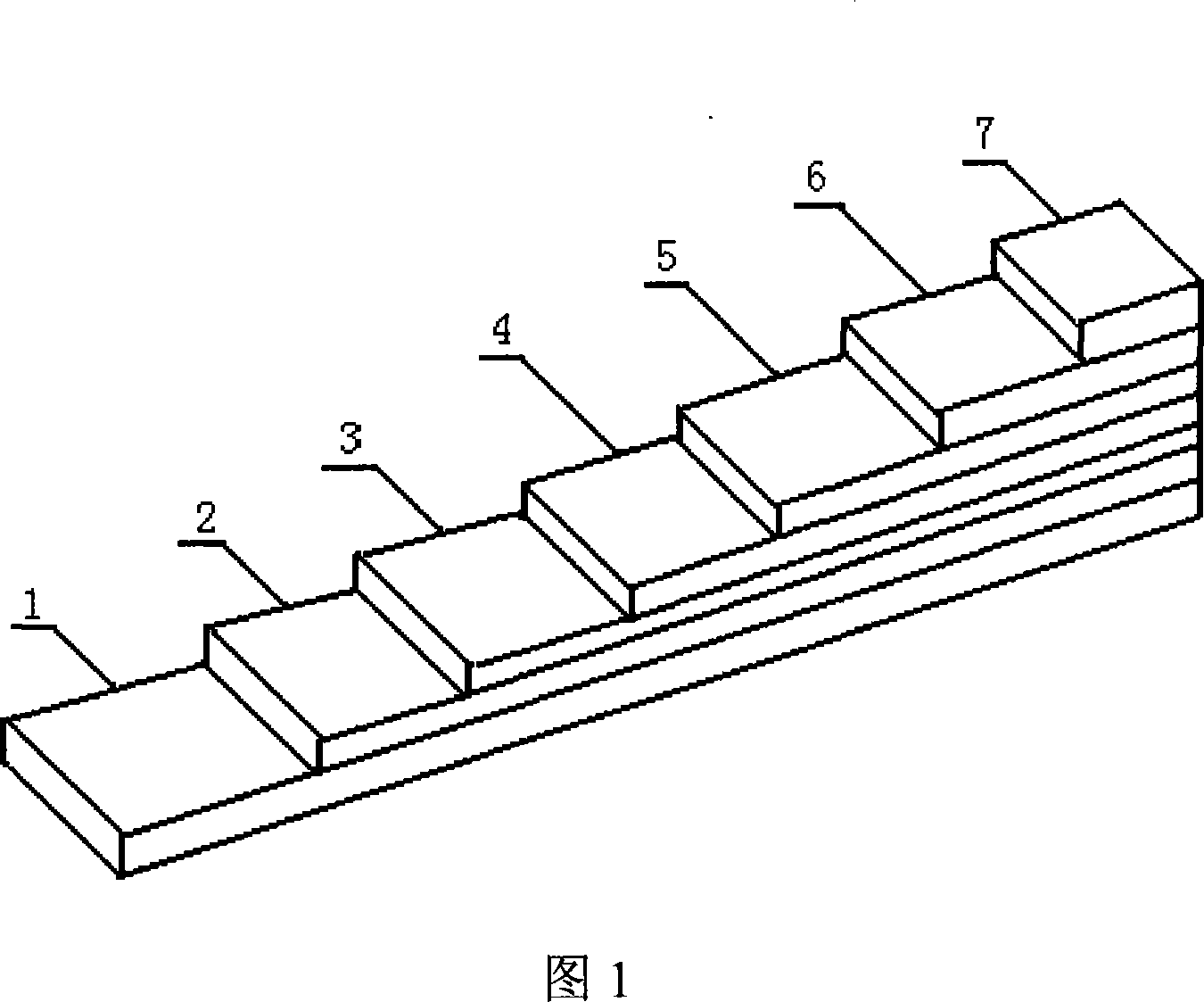

[0067] See Figure 1. The base material of the wall decoration board is a high-density fiber reinforced cement board. Firstly, the base 1 is sanded and smoothed and the dust on the surface is removed, and then a layer of UV-curable penetrant 2 is applied on the surface of the base of the wall decoration board. 30 minutes, natural leveling, the dosage is 150g / m 2 , and then roll coating one deck thickness is the ultraviolet curing putty 3 of 50um, enters the light curing machine that 2 9.6kw ultraviolet lamps (high pressure mercury lamps) are housed, and the transmission speed is 20 meters per minute, after curing, again in ultraviolet light The cured putty surface roller coating one deck thickness is the ultraviolet curing sealing clear primer 4 of 30um, enters and is equipped with 2 13kw ultraviolet lamps (high-pressure mercury lamp), and the light curing machine that transmission speed is 20 meters / min, after curi...

Embodiment 2

[0073] Example 2. Imitation wood grain wall decoration board

[0074] See Figure 1. The base material of the wall decoration board is a calcium silicate board. Firstly, the substrate 1 is sanded and smoothed and the dust on the surface is removed, and then a layer of UV-curable penetrant 2 is rolled on the surface of the base of the wall decoration board. Leveling for 3 minutes, the dosage is 100g / m 2 , and then roll coating one deck thickness is the ultraviolet curing putty 3 of 30um, enters the light curing machine that 2 9.6kw ultraviolet lamps (high pressure mercury lamps) are housed, and transmission speed is 25 meters per minute, after curing, again in ultraviolet light The surface of the cured putty is roller-coated with a layer of UV-curable sealing clear primer 4 with a thickness of 40um, leveled under infrared rays at a temperature of 50°C for 1 minute, and then enters the place where three 9.6kw UV lamps (high-pressure mercury lamps) are installed, and the transmis...

Embodiment 3

[0080] Example 3. Imitation brushed metal effect wall decoration panel

[0081] See Figure 1. The base material of the wall decoration board is a glass fiber reinforced magnesium oxide board. First, the base 1 is sanded and smoothed and the dust on the surface is removed, and then a layer of UV-curable penetrant 2 is rolled on the surface of the base of the wall decoration board. Leveling under the infrared ray for 1 minute, the dosage is 50g / m 2 , and then roll coating a layer of UV curing putty 3 with a thickness of 30um, enter the light curing machine equipped with 2 13kw UV lamps (high pressure mercury lamps), and the transmission speed is 30 m / min. Putty surface drench coating one deck thickness is 150um UV curing sealing clear primer 4, enters and is equipped with 3 13kw ultraviolet lamps (high pressure mercury lamps), the light curing machine that transmission speed is 30 meters / minute, after curing, again Hot-stamp a layer of thermal transfer film 5 with a brushed me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com