Flexible lamina for laser impact treatment

A laser shock and flexible technology, used in laser welding equipment, manufacturing tools, welding equipment, etc., can solve the problems of large dispersion of experimental data, cumbersome operation and installation, poor process stability, etc., to achieve a simple production process and good consistency. , the thickness of the precise and controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Example 1: The ratio of the flexible constrained layer is 45% M, 50% N, 5% P, and the light transmittance is 95.9%.

Embodiment 2

[0018] Example 2: The ratio of the flexible constrained layer is 50% M, 45% N, 5% P, and the light transmittance is 94.4%.

Embodiment 3

[0019] Example 3: The ratio of the flexible constrained layer is 55% M, 35% N, 10% P, and the light transmittance is 88.3%

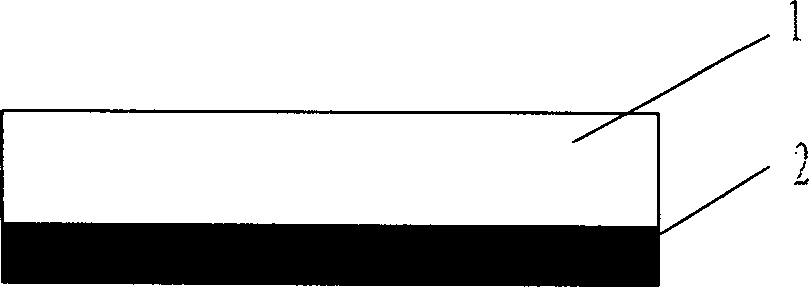

[0020] The energy absorbing layer that the present invention adopts is 86-1 type black paint coating, can absorb the laser light that wavelength is 1.06um almost completely, has improved the coupling efficiency of energy on the one hand, has changed the cooling process of plasma on the other hand, namely The effect of the former is the improvement of the pressure effect, and the effect of the latter is the increase of the pressure effect time.

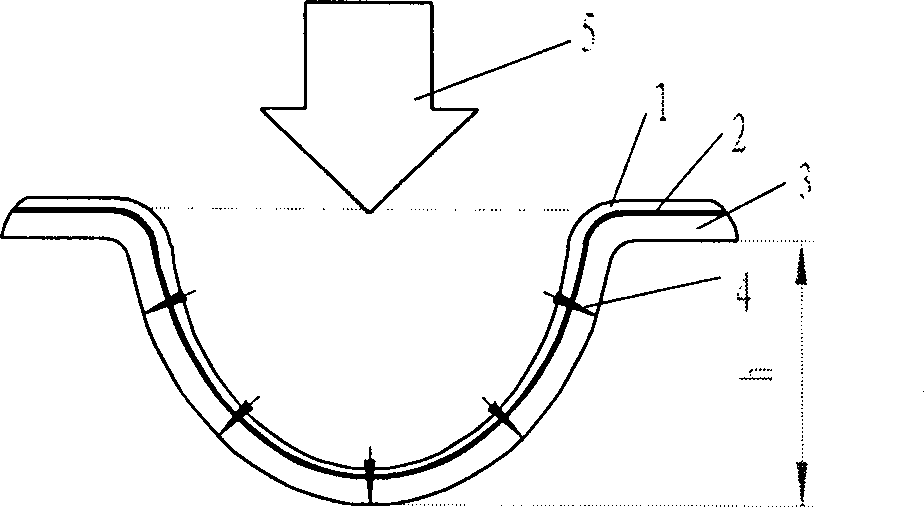

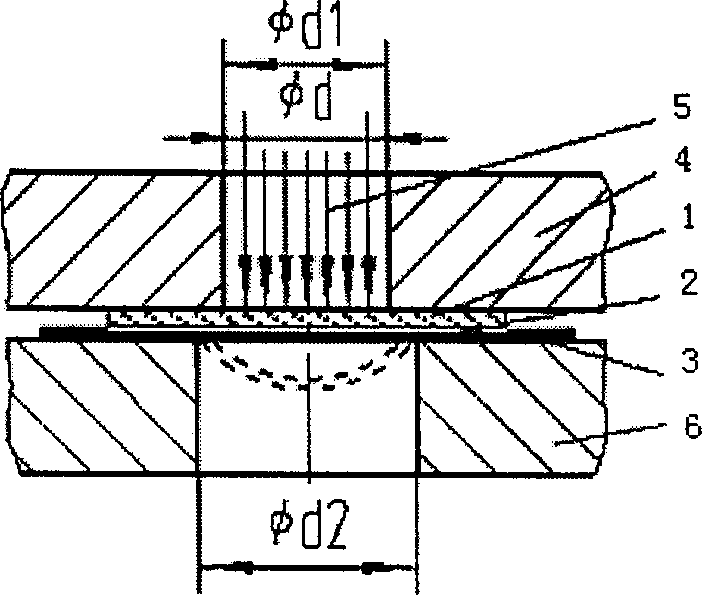

[0021] In order to determine the effect of the flexible film composed of constrained layer and energy absorbing layer with different thicknesses on the effect of laser shock treatment, the Figure 3 The display device measures the deformation of the sheet under the action of the same power density: the flexible film adheres to the surface of the sheet 3, and the sheet 3 is tightened by the clamping plate 4 on the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com