Metal porous membrane preparation device based on laser shock wave effect

A technology for porous metal and preparation devices, applied in membrane technology, semi-permeable membrane separation, chemical instruments and methods, etc., can solve problems such as complex processes, achieve good toughness, avoid cracking, and avoid deceleration effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

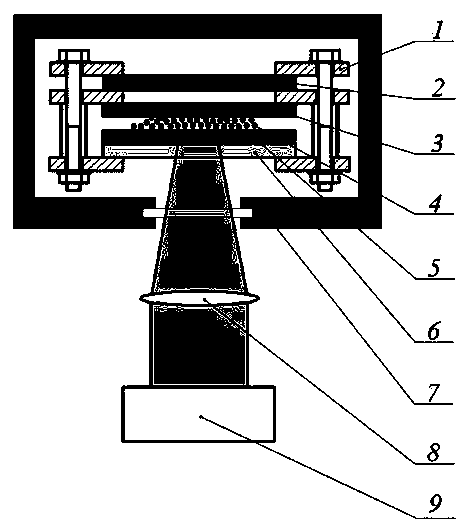

[0020] The metal film 1 described in this example is a stainless steel film with a thickness of 10 μm; the support mesh 3 is a 50 mesh stainless steel woven mesh; the distance between the metal film 2 and the support mesh 3 is 1 mm; the hard microparticles 4 are 10nm SiC particles; the absorption layer 5 is an aluminum foil with a thickness of 100μm; the confinement layer 6 is a K9 optical glass with a thickness of 3mm; the high-energy pulsed laser that the laser generator 9 can emit has a pulse width of 10ns and a maximum pulse energy of 12J.

[0021] The method for preparing a metal porous film based on the laser shock wave effect of the present invention performs the following steps:

[0022] 1) Cover the absorbing layer 5 on the surface of the constrained layer 6;

[0023] 2) Cover the surface of the absorption layer 5 with a layer of hard microparticles 4 with a thickness of about 1 μm;

[0024] 3) Cover the supporting net 3 on the hard microparticle 4;

[0025] 4) Use the clamp 1...

Embodiment 2

[0030] The metal film 1 described in this example is a titanium film with a thickness of 50 μm; the support mesh 3 is a 50 mesh stainless steel woven mesh; the distance between the metal film 2 and the support mesh 3 is 3 mm; the hard microparticles 4 are 0.2μm WC particles; absorption layer 5 is aluminum foil with a thickness of 100μm; confinement layer 6 is K9 optical glass with a thickness of 3mm; the high-energy pulsed laser that can be emitted by laser generator 9 has a pulse width of 20ns and a maximum pulse energy of 12J .

[0031] A method for laser shock processing curved surfaces of the present invention performs the following steps:

[0032] The method for preparing a metal porous film based on the laser shock wave effect of the present invention performs the following steps:

[0033] 1) Cover the absorbing layer 5 on the surface of the constrained layer 6;

[0034] 2) Cover the surface of the absorption layer 5 with a layer of hard microparticles 4 with a thickness of abo...

Embodiment 3

[0041] The metal film 1 described in this example is a stainless steel film with a thickness of 100 μm; the support mesh 3 is a 50 mesh stainless steel woven mesh; the distance between the metal film 2 and the support mesh 3 is 10 mm (guaranteed by the clamp 1); Particle 4 is a SiC particle with a particle size of 10 μm; the absorption layer 5 is an aluminum foil with a thickness of 100 μm; the constraining layer 6 is K9 optical glass with a thickness of 3 mm; the high-energy pulsed laser that the laser generator 9 can emit has a pulse width of 30 ns, The highest pulse energy is 12J.

[0042] A method for laser shock processing curved surfaces of the present invention performs the following steps:

[0043] The method for preparing a metal porous film based on the laser shock wave effect of the present invention performs the following steps:

[0044] 1) Cover the absorbing layer 5 on the surface of the constrained layer 6;

[0045] 2) Cover the surface of the absorption layer 5 with a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com