Laser shock enhancement device adopting macromolecular restraint layer

A technology of laser shock strengthening and confinement layer, which is applied in the field of laser processing to achieve the effect of reliable restraint, stable strengthening effect and guaranteeing stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

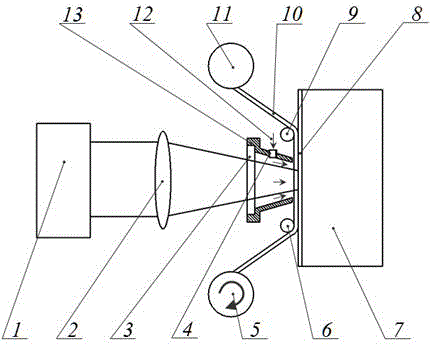

[0020] The specific implementation is as follows: compressed air 12 enters the nozzle 13 through the air nozzle 4, and is ejected from the nozzle 13, acts on the constrained layer 10, and compresses the constrained layer 10 to the surface of the absorbing layer; the laser 1 sends a pulse laser, and the laser After the beam is focused by the focusing lens 2, it passes through the glass window 3 and the constraining layer 10, and irradiates the surface of the absorbing layer to complete a laser shock treatment; while the laser 1 emits laser pulses, the driving wheel 5 rotates to drive the constraining layer 10 to perform a laser shock treatment. Feed motion, the workpiece 7 is also fed at the same speed. The present invention realizes the pressing of the constrained layer 10 on the surface of the workpiece 7, the replacement of the unused part of the constrained layer 10 with the used part and the continuous implementation of the laser shock strengthening process.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com