High-pressure flushing system for trailing suction hopper dredger and with self-exciting oscillation pulsed jet flow nozzles

A technology of trailing suction dredger and self-excited oscillation, which is applied in the direction of earth mover/shovel, mechanically driven excavator/dredger, construction, etc. Low wear and high reliability results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to further understand the invention content, characteristics and effects of the present application, the following embodiments are listed hereby, and the present application is described in detail as follows in conjunction with the accompanying drawings:

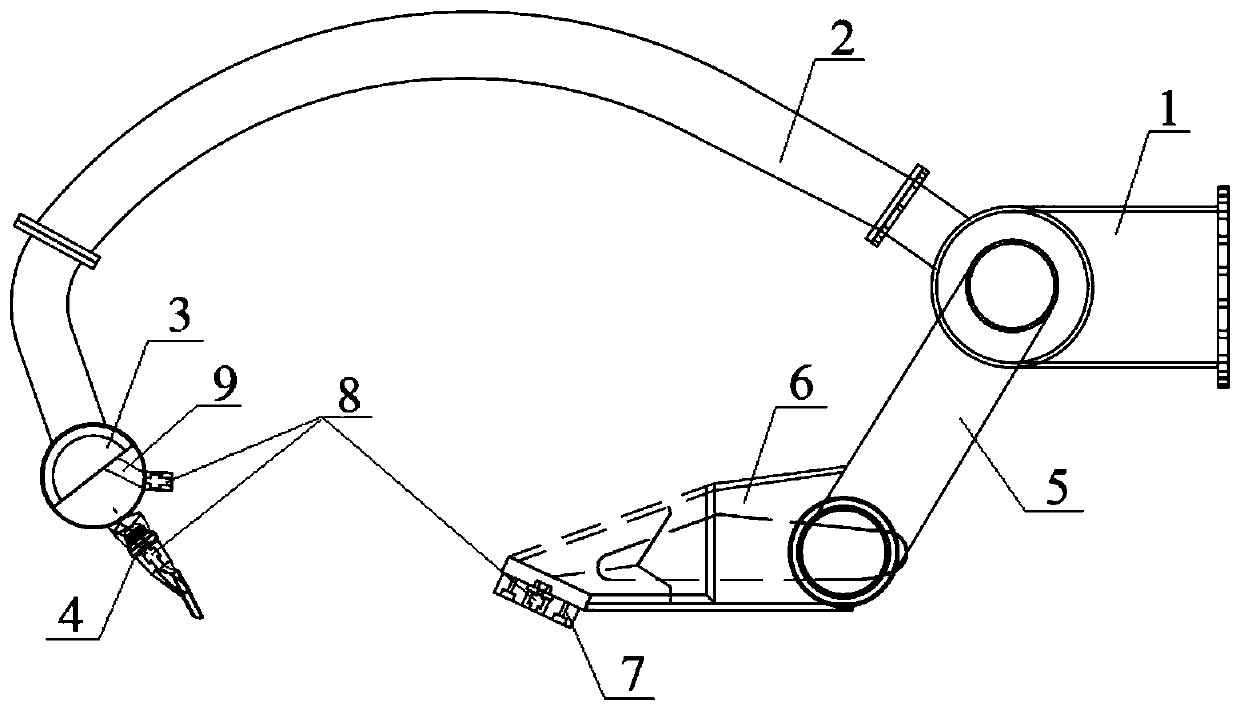

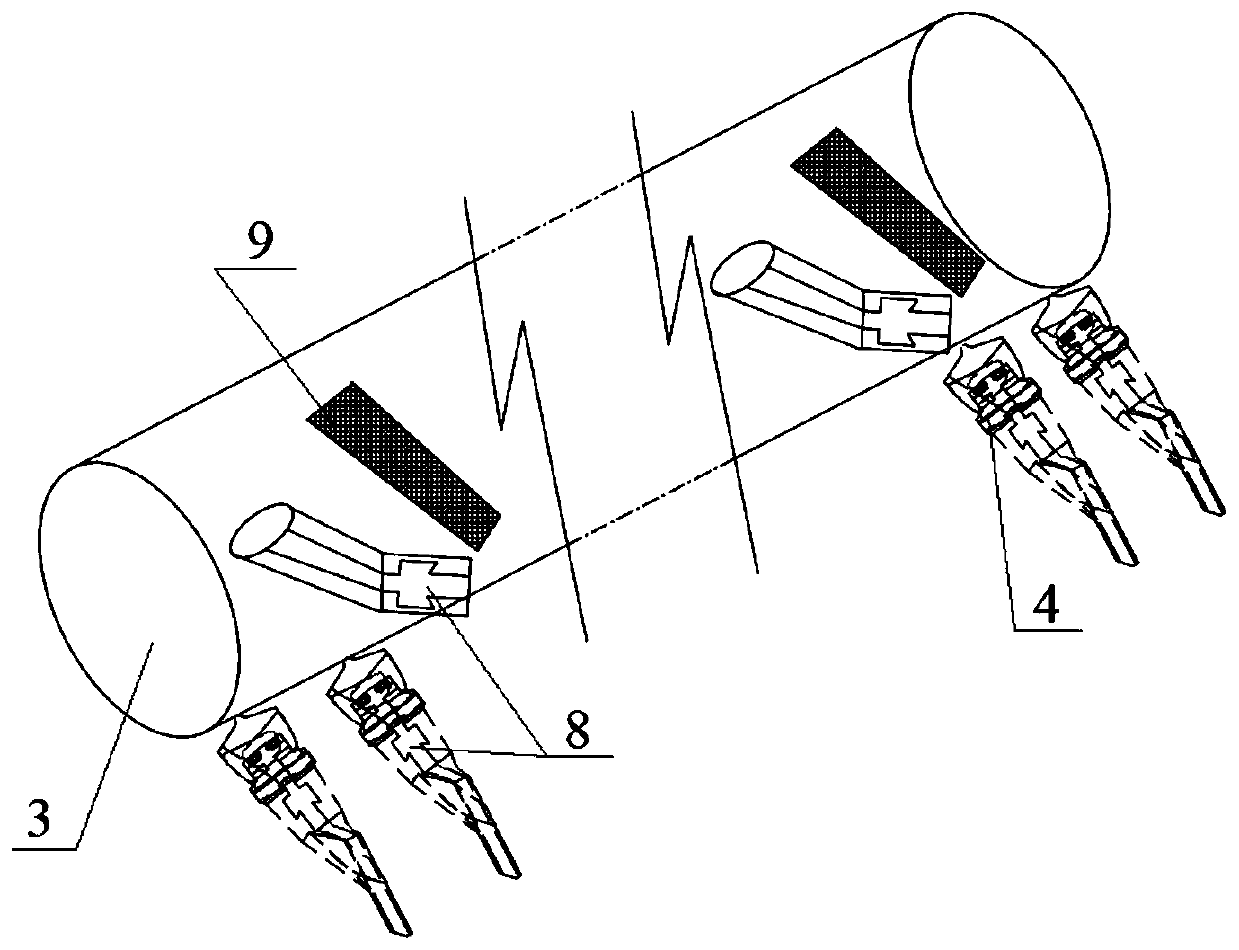

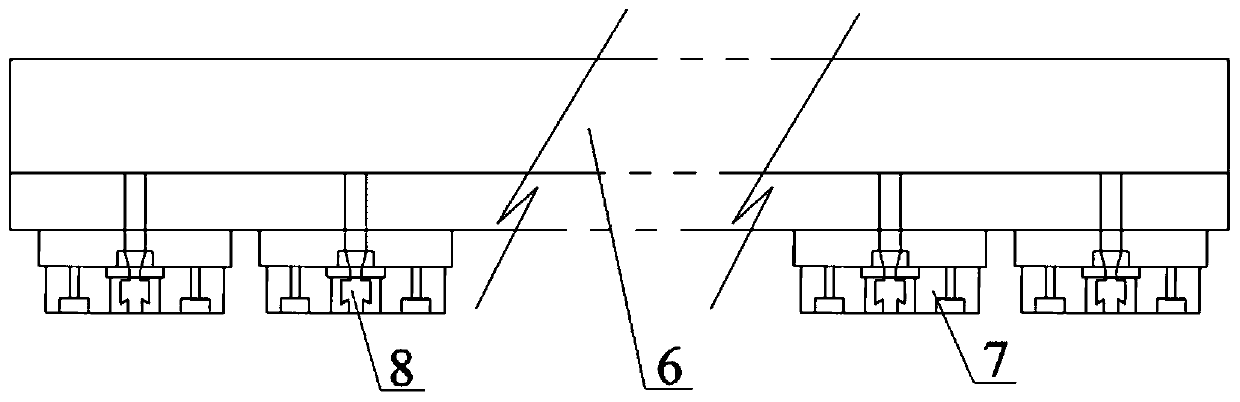

[0037] refer to figure 1 and figure 2 , Rake suction dredger with self-excited oscillation pulse jet nozzle high-pressure flushing system, including main pipeline 1, rake tooth branch pipeline 2, rake tooth high pressure water tank 3, rake tooth 4, wear-resistant block branch pipeline 5, wear-resistant block high-pressure water tank Water tank 6, wear-resistant block 7, self-excited oscillation pulse jet nozzle 8, grid 9, upper nozzle 10, oscillation chamber 11, collision wall 12, lower nozzle 13.

[0038] The inlet of the main pipeline 1 is connected to the outlet pipeline of the high-pressure water pump through a flange, and its outlet is divided into two routes, one is connected with the rake high-pressu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com