A preparation method and device for nanoscale dispersion liquid of inorganic materials

A technology of inorganic materials and dispersion liquid, applied in the direction of grain processing, etc., can solve the problems of long time consumption, low processing efficiency, easy material blockage, etc., and achieve the effect of improving strong dispersibility, improving production efficiency and improving production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

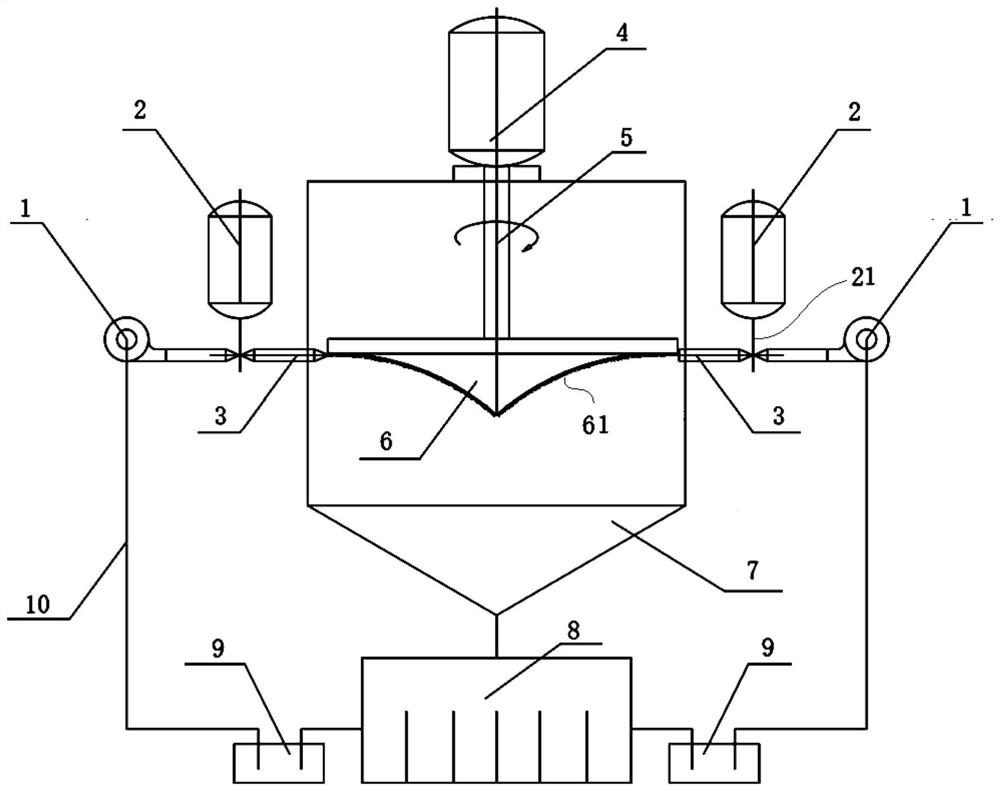

[0039] as Figure 1-2 as shown. The present invention discloses an inorganic material nanoscale dispersion preparation apparatus, comprising a stirring paddle disposed within the sealed container 7; the stirring paddle is connected to an external motor 4 by turning the shaft rod 5, the external motor 4 drives the stirring paddle to rotate within the sealed container 7; the stirring paddle is a friction turntable with a profile shape of a V-shaped structure 6;

[0040] At the bottom outlet of the sealed container 7, the inlet of the filter box 8 is connected through pipe 10;

[0041] The outlet of the filter box 8 is connected sequentially through the pipeline 10 to the reservoir 9, the high-pressure pump 1 and the nozzle 3;

[0042] The nozzle of the nozzle 3 extends into the sealed vessel 7, located on the lower side of the edge of the friction turntable 6; the nozzle of the nozzle 3 is 1 to 3cm from the surface of the friction turntable 6.

[0043]Between the high-pressure pump 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com