Air-powered rotary-cut type pipeline dredging apparatus

A rotary cutting and pipeline technology, which is used in indoor sanitary pipeline installations, water supply installations, buildings, etc., can solve problems such as low work efficiency, high cost, and airflow loss, achieve good social and economic benefits, and be easy to manufacture or transform. , the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

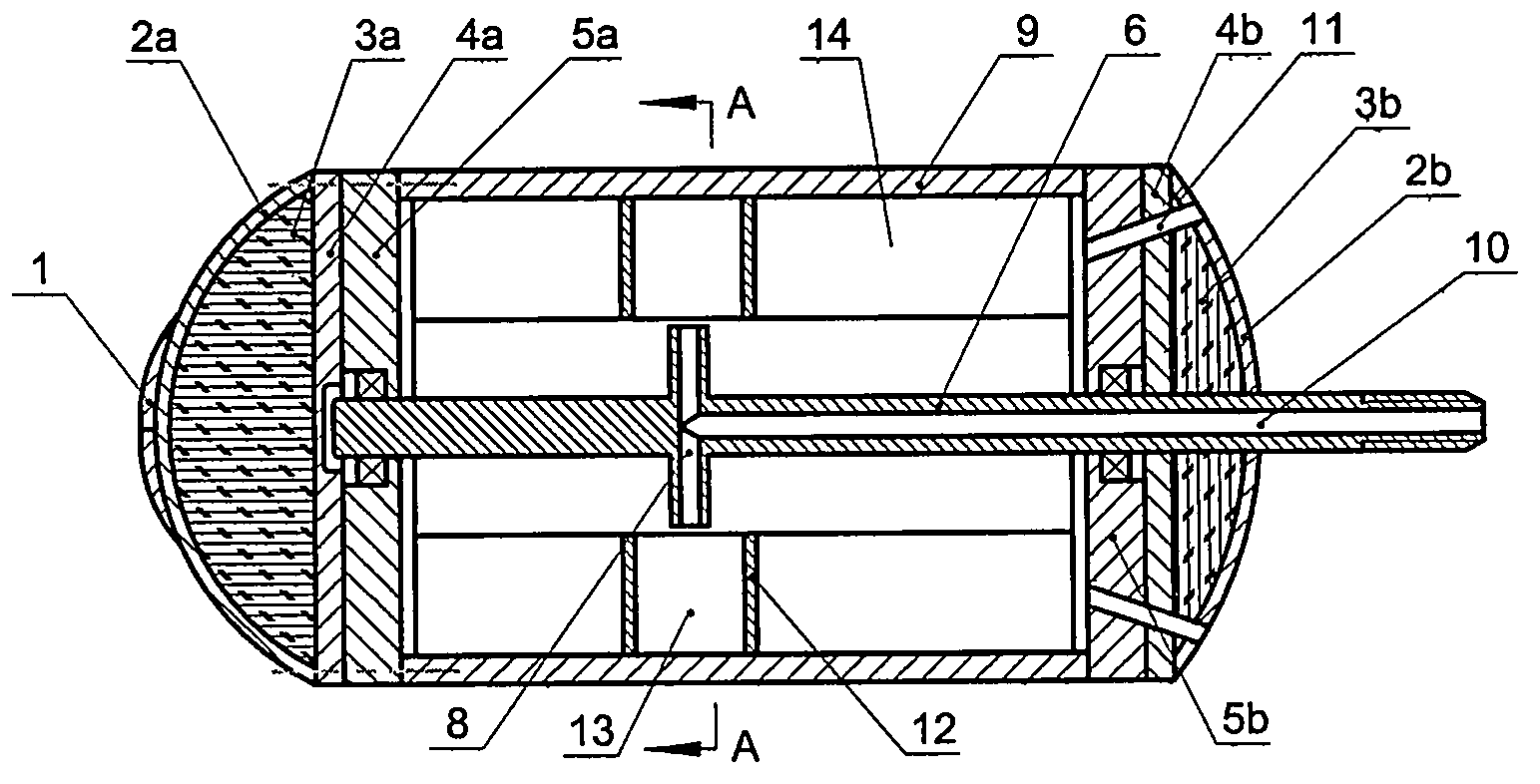

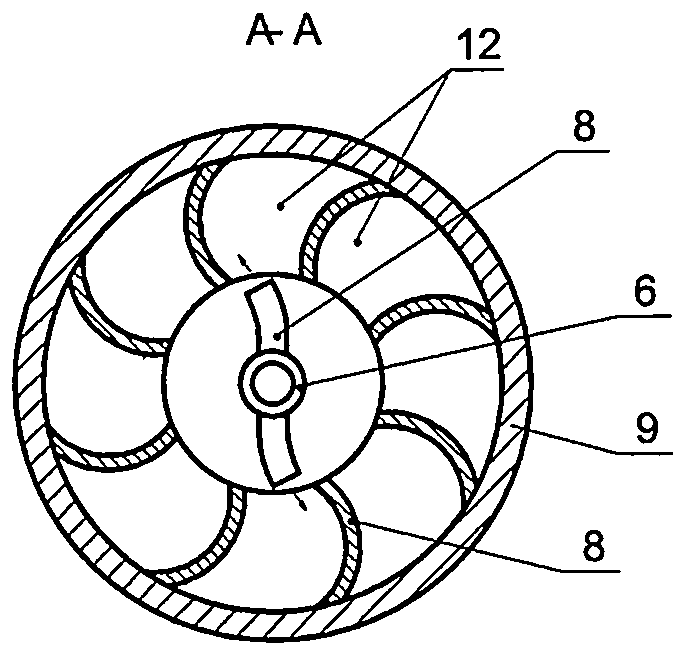

[0035] Embodiment 1: see figure 1 , figure 2 , a pneumatic rotary cutting type pipeline dredging device, including a casing, an air shaft 6, wherein the casing includes a hollow cylinder 9 and fixed plates 5a, 5b fixed at the front and rear ends of the hollow cylinder, and the fixed plates at the front and rear ends 5a, 5b are also respectively fixed with front and rear baffles 4a, 4b on the outer side surfaces, and the sealing covers outside the fixed baffles 4a, 4b at the front and rear ends are positioned at the outside of the front side sealing covers to have a stirring and cutting mechanism 1, and the hollow cylinder 9 A certain number of axial vanes 14 are evenly distributed and fixed on the inner wall, and the air shaft 6 is installed on the front and rear fixing plates 5a, 5b of the casing through bearings, and its rear end passes through the rear fixing plate 5b and connects with the air delivery pipe of the air compressor. connection, the rear part of the air shaft...

Embodiment 2

[0041] Example 2: see image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8-1 , Figure 8-2 , the numbering is the same as in Embodiment 1, the meaning is the same, and the same parts will not be repeated. The difference is that at least two jet surfaces are arranged on the jet pipe, each jet plane is parallel to each other, and each jet surface is provided with at least two jet surfaces. Centrosymmetric jet tube.

[0042] Transverse baffles are respectively fixed on both sides of the opposite axial vanes on each air jet surface, that is, there is a groove-like structure surrounded by front and rear baffles, axial vanes and the inner wall of the hollow cylinder at the corresponding position on each air jet surface.

Embodiment 3

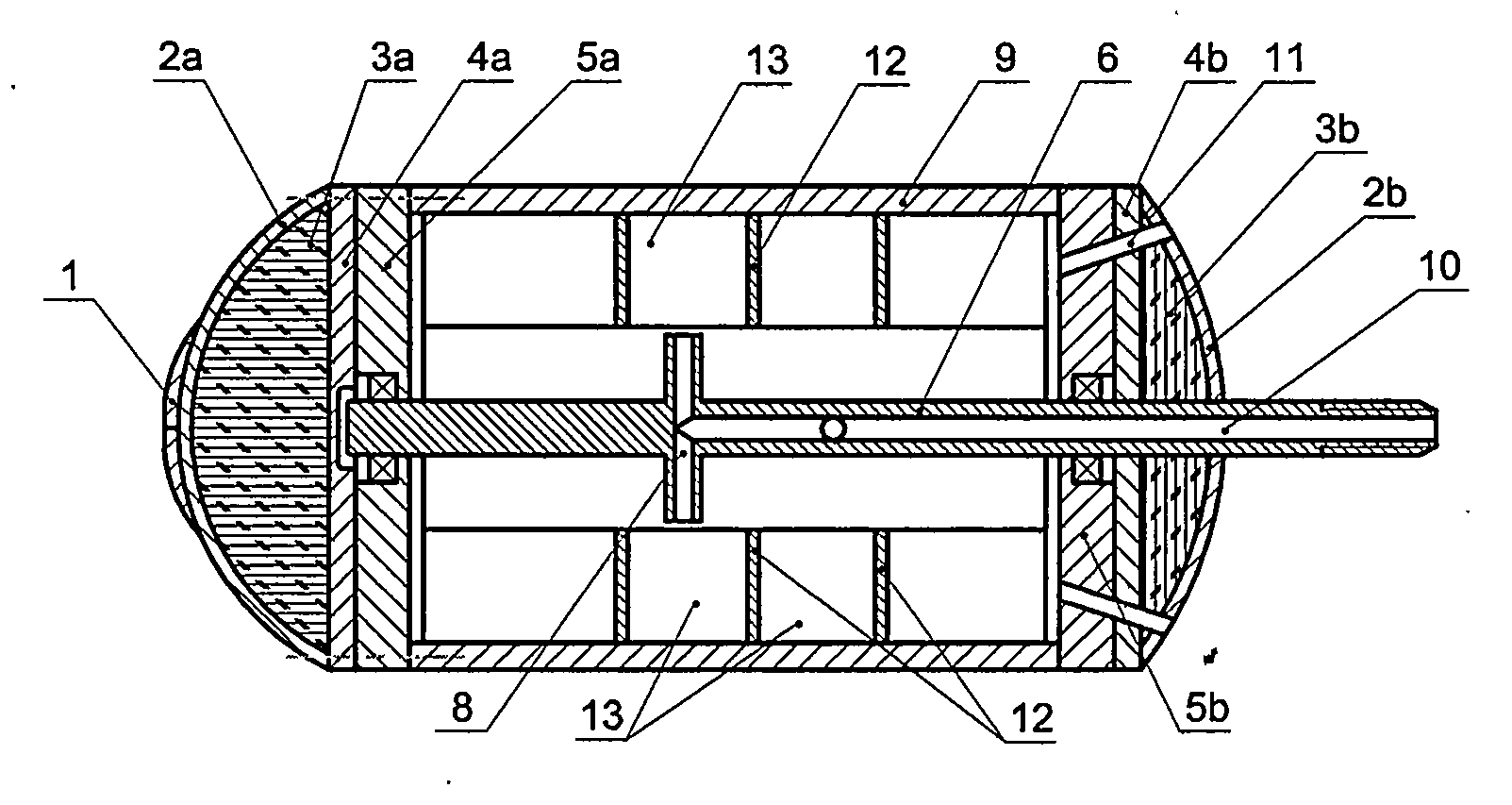

[0043] Embodiment 3: see Figure 9 , Figure 10 , a pneumatic rotary cutting type pipeline dredging device, including a casing, an air shaft 6, wherein the casing includes a hollow cylinder 9 and fixed plates 5a, 5b fixed at the front and rear ends of the hollow cylinder, and the fixed plates at the front and rear ends 5a, 5b are also fixed with front and rear baffles 4a, 4b respectively on the outer side surfaces, and the sealing covers outside the fixed baffles 4a, 4b at the front and rear ends are positioned at the outside of the front side sealing covers to have a stirring and cutting mechanism 1, and the air shaft 6 passes through the bearings. Installed on the front and rear fixing plates 4a and 4b of the casing, the rear end of which passes through the rear fixing plate 4b and is connected with the air delivery pipe of the air compressor, the rear part of the air shaft 6 is a hollow structure and an air injection pipe 8 is arranged on it , the inner end of the jet pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com