Preparation method and application of decompression and augmented injection agent for water injection well

A technology for water injection wells and injection boosters, which is applied to chemical instruments and methods, earthwork drilling, wellbore/well components, etc. It can solve problems such as complex construction, hazards of formation water quality, and inability to remove formation blockages, so as to simplify the construction process , water injection pressure increases, the effect of reducing construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

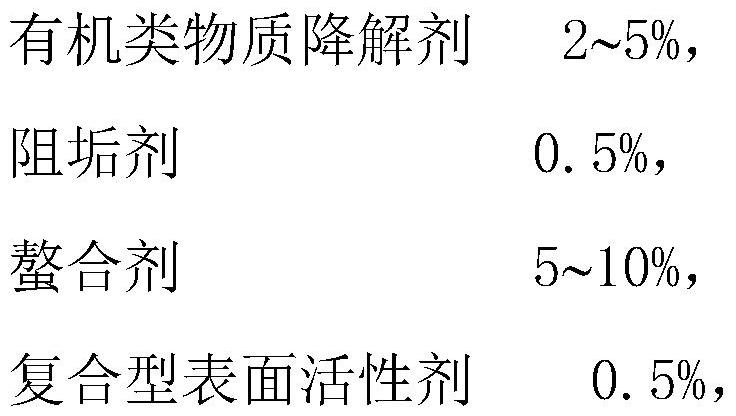

[0028] This embodiment relates to an injection well a buck increase, including each component of the following mass:

[0029]

[0030] The organic substance degradation agent is sodium trichloroic acid. The strong oxidation property of sodium trichloride is used, which can cause clogging water wells due to polymer, formation grain transfer, bacteria and metabolites, inorganic substance, etc., and perform an oxidized deep penetration. Maximize the penetration rate of the proximal well.

[0031] The chelating agent is sodium ethylenediamine tetraacerate.

[0032] The composite surfactant is a mixture of coconut diethylenesulfylsulfine benits and petroleum sulfonate in a mass ratio of 3 / 2. The organic hydrocarbon substance of the inorganic scale surface is replaced by a surfactant, and then the chelating agent is soluble to the inorganic salt wellbore and the dimensions in the formation in the formation have been used to maximize the effect of the interpolation. Finally utilized Sc...

Embodiment 2

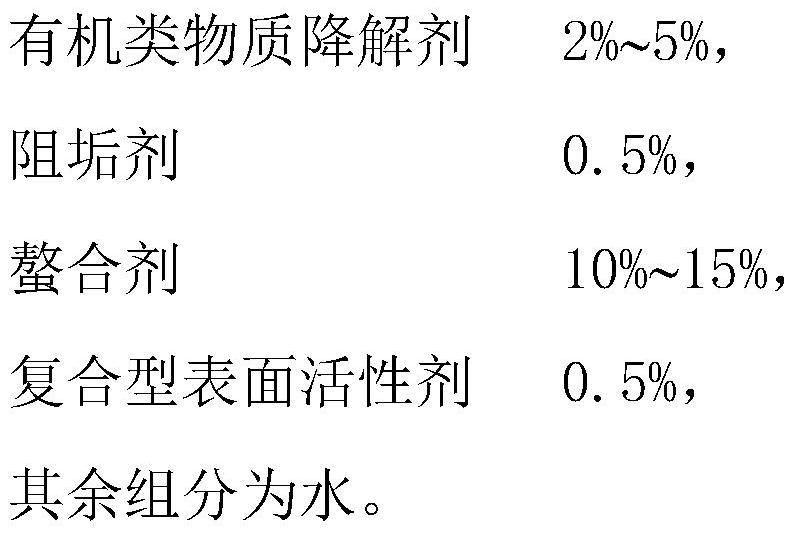

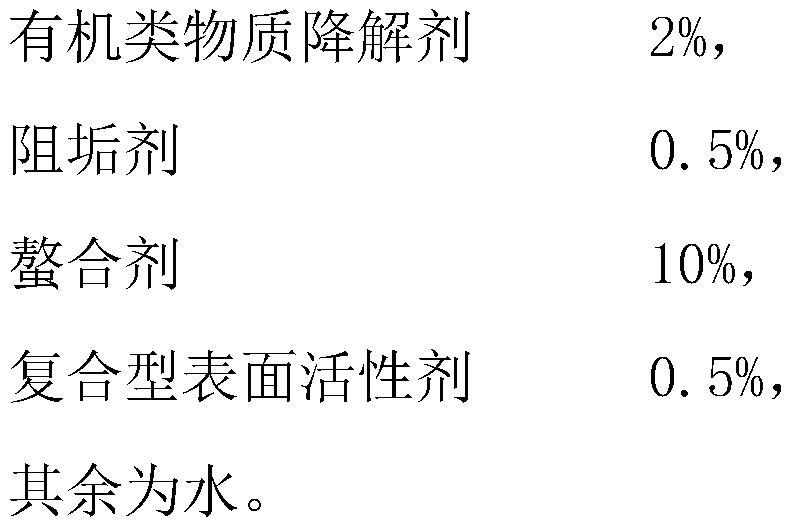

[0041] This embodiment relates to an injection well a buck increase, including each component of the following mass:

[0042]

[0043] The organic substance degradation agent is sodium trichloroic acid. The strong oxidation property of sodium trichloride is used, which can cause clogging water wells due to polymer, formation grain transfer, bacteria and metabolites, inorganic substance, etc., and perform an oxidized deep penetration. Maximize the penetration rate of the proximal well.

[0044] The chelating agent is ethylenediamine tetracetate tetra sodium salt + ammonia trilyaceate, and its mass ratio is 2 / 1.

[0045] The composite surfactant is a mixture of coconut diethylenesulfylsulfine benits and petroleum sulfonate in a mass ratio of 3 / 2. The organic hydrocarbon substance of the inorganic scale surface is replaced by a surfactant, and then the chelating agent is soluble to the inorganic salt wellbore and the dimensions in the formation in the formation have been used to ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com