Split nozzle cap tube of welding gun for gas metal arc welding process

A melting gas and arc welding technology, applied in arc welding equipment, manufacturing tools, welding rod characteristics, etc., can solve the problems of high-standard welding operations, lack of similar design reference schemes for forming, and inability to produce, so as to improve utilization rate, Improve the degree of freedom and flexibility, the effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

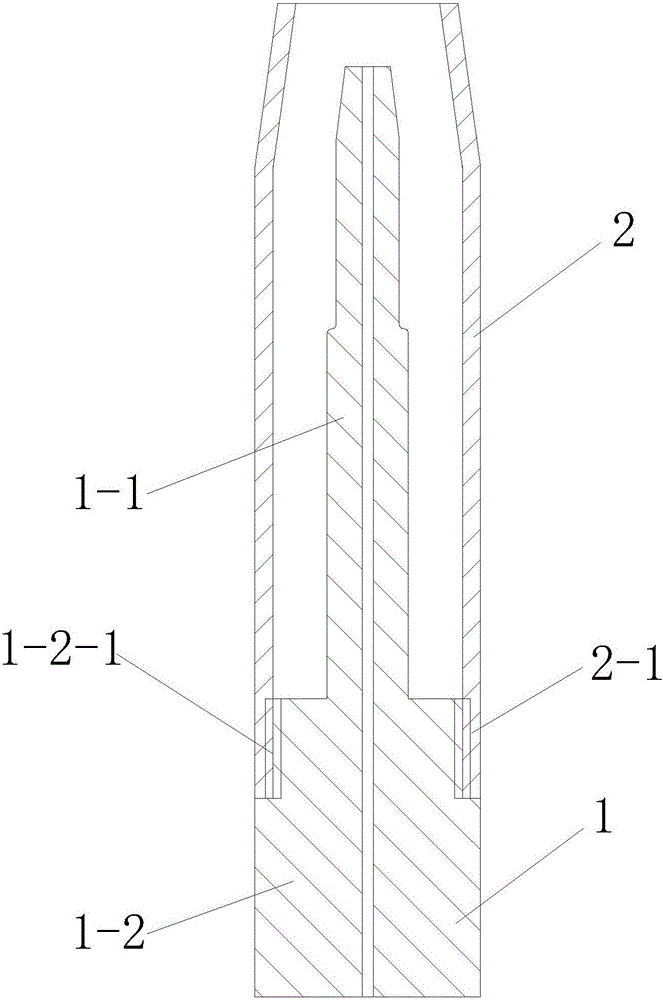

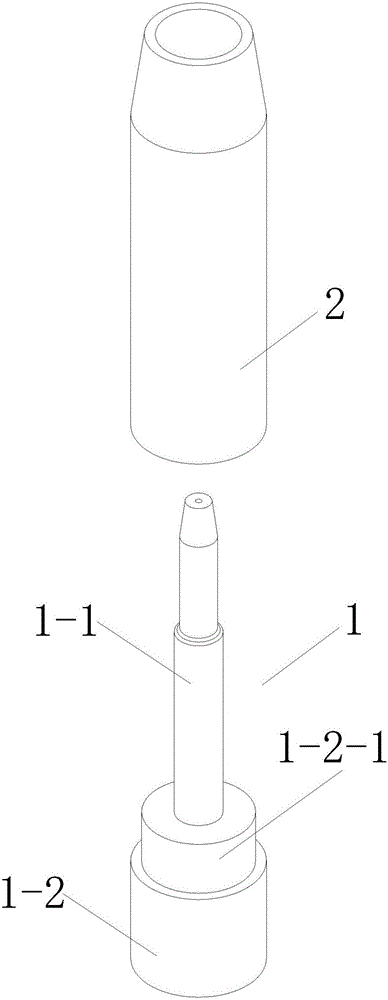

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings.

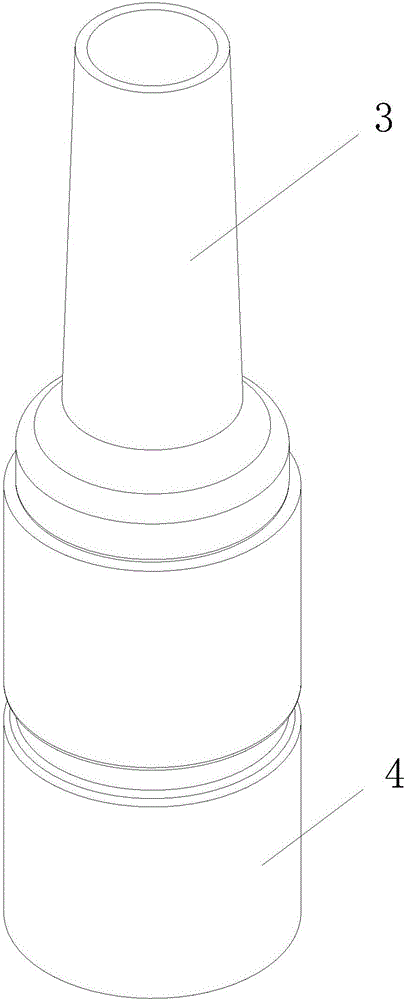

[0024] like Figure 3 to Figure 5 As shown, the split nozzle cap barrel of the welding torch for MIGA welding process of the present invention includes a reducing cap barrel end 3 and a transition sleeve 4, and the reducing diameter cap barrel end 3 includes an integrally formed conical nozzle opening 3- 1 and the cap tube connecting portion 3-2; the transition sleeve 4 is a straight cylinder structure, the upper section of its inner wall is provided with a first connecting section 4-1, and the lower section of its inner wall is provided with a second connecting section 4-2, and the transition The middle section of the outer wall of the sleeve 4 is provided with an annular groove 4-3; the cap cylinder connecting portion 3-2 is coaxially nested inside the first connecting section 4-1, and the two are fixedly connected. The overall radial height of the reducin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com