Paint spraying device and method

A spraying device and paint technology, applied in the field of painting, can solve the problems of difficulty in improving processing quality, small spraying pressure of paint spraying gun, small spraying area, etc., so as to improve painting work efficiency and processing effect, increase spraying pressure, and increase spraying area Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A method for spraying paint using the paint spraying device, comprising the following steps:

[0023] A, paint mixing, add diluent, curing agent, paint into paint bucket 2 according to the following parts by weight and mix evenly,

[0024] Thinner 4

[0025] Hardener 4

[0026] paint 11;

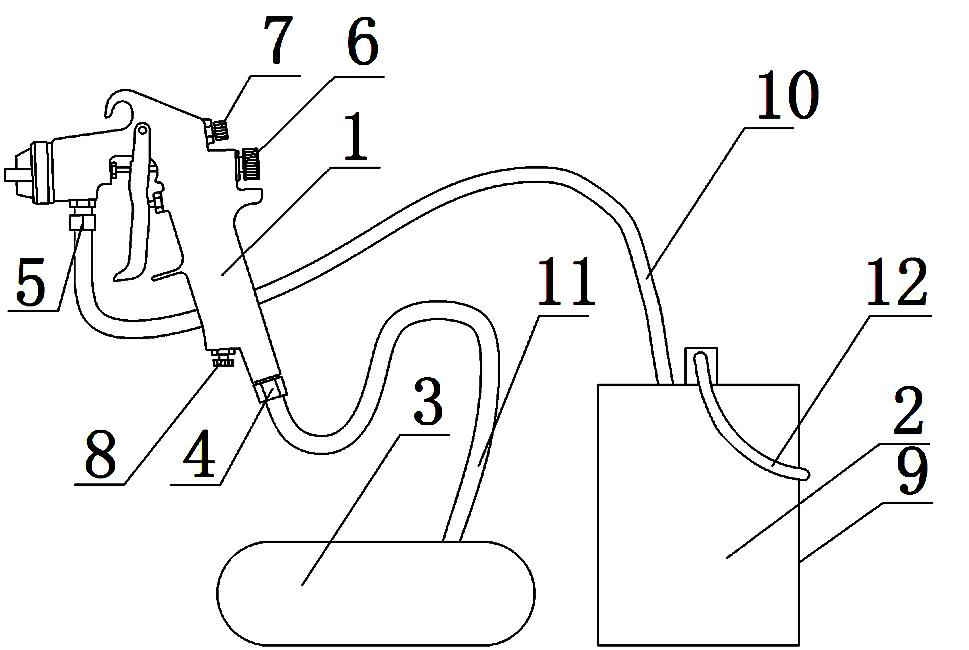

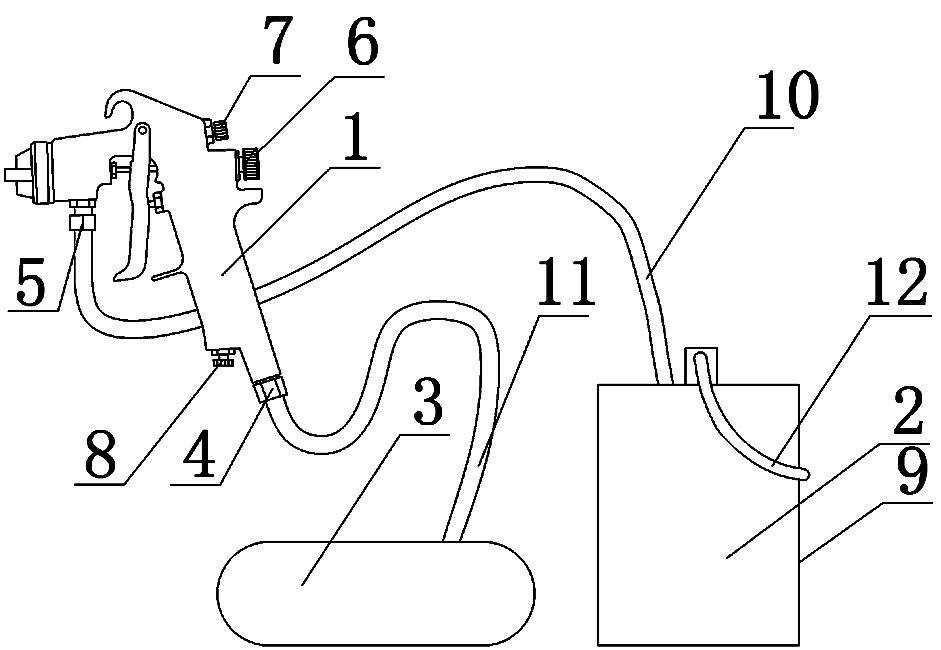

[0027] B. Adjust the gun, adjust the paint regulating valve 6, the air intake coarse adjustment valve 7, and the air intake fine adjustment valve 8, so that the paint sprayed by the paint spray gun 1 is evenly sprayed.

[0028] C. Surface treatment to remove rust and impurities on the surface.

[0029] D. Spraying.

Embodiment 2

[0031] A method for spraying paint using the paint spraying device, comprising the following steps:

[0032] A, paint mixing, add diluent, curing agent, paint into paint bucket 2 according to the following parts by weight and mix evenly,

[0033] Thinner 2

[0034] Hardener 2

[0035] paint 8;

[0036] B. Adjust the gun, adjust the paint regulating valve 6, the air intake coarse adjustment valve 7, and the air intake fine adjustment valve 8, so that the paint sprayed by the paint spray gun 1 is evenly sprayed.

[0037] C. Surface treatment to remove rust and impurities on the surface.

[0038] D. Spraying.

Embodiment 3

[0040] A method for spraying paint using the paint spraying device, comprising the following steps:

[0041] A, paint mixing, add diluent, curing agent, paint into paint bucket 2 according to the following parts by weight and mix evenly,

[0042] Thinner 3

[0043] Hardener 3

[0044] paint 10;

[0045] B. Adjust the gun, adjust the paint regulating valve 6, the air intake coarse adjustment valve 7, and the air intake fine adjustment valve 8, so that the paint sprayed by the paint spray gun 1 is evenly sprayed.

[0046] C. Surface treatment to remove rust and impurities on the surface.

[0047] D. Spraying.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com