Vacuum steam recovery device for steam turbine

A recovery device and steam turbine technology, which is applied in the direction of steam engine equipment, steam recovery, mechanical equipment, etc., can solve the problems that the latent heat of the exhaust steam of the steam turbine cannot be utilized, the pressure difference of the steam turbine is increased, and water resources are wasted, so as to achieve a large suction force and reduce Small power consumption, the effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

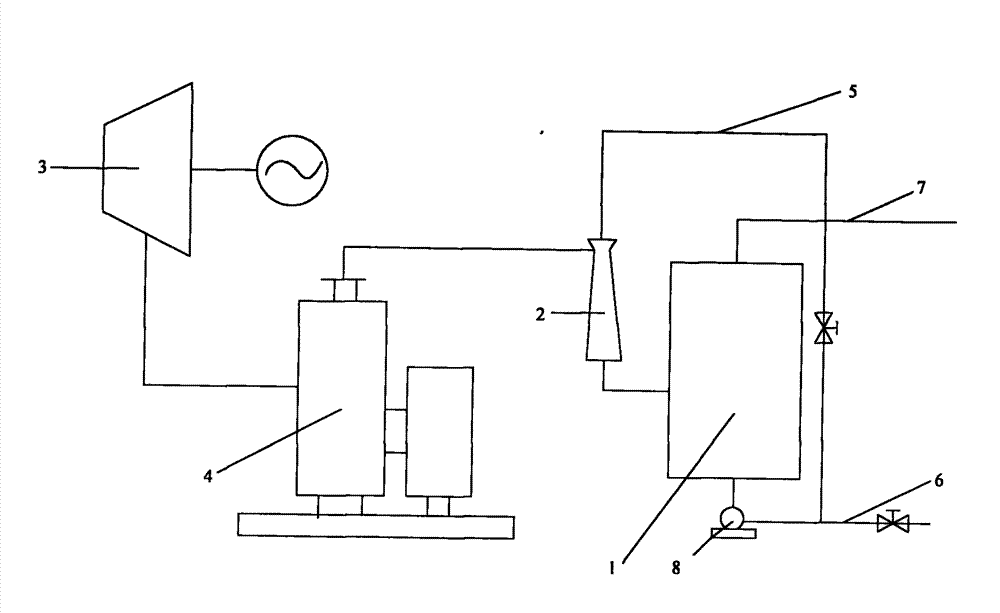

[0016] see figure 1 , a steam turbine vacuum steam recovery device, including a steam turbine 3, a closed exhaust steam recovery tank 1 and a jet pump 2, the jet pump is installed vertically, and a high pressure pump 8 is connected to the bottom of the closed exhaust steam recovery tank , the outlet of the high-pressure pump is connected to the jet pipeline 5, the jet outlet of the jet pump is connected to the inlet of the closed exhaust steam recovery tank, the jet inlet is connected to the outlet of the jet pipeline, and the suction inlet is connected to the steam turbine through the fan 4 The exhaust steam outlet, the closed exhaust steam recovery tank maintains a pressure sufficient to convert at least part of the exhaust steam into liquid water.

[0017] The length of the jet pump is not less than 3 meters. The height drop of the jet pump itself can increase the jet velocity and jet pressure, thereby enhancing the suction such as the suction force at the mouth.

[0018]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com