Method for stripping and removing coating on surface of base body

A surface coating and coating technology, applied in the direction of cleaning methods and utensils, chemical instruments and methods, etc., can solve problems such as substrate damage, achieve the effects of ensuring service life, improving stripping efficiency, and prolonging action time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

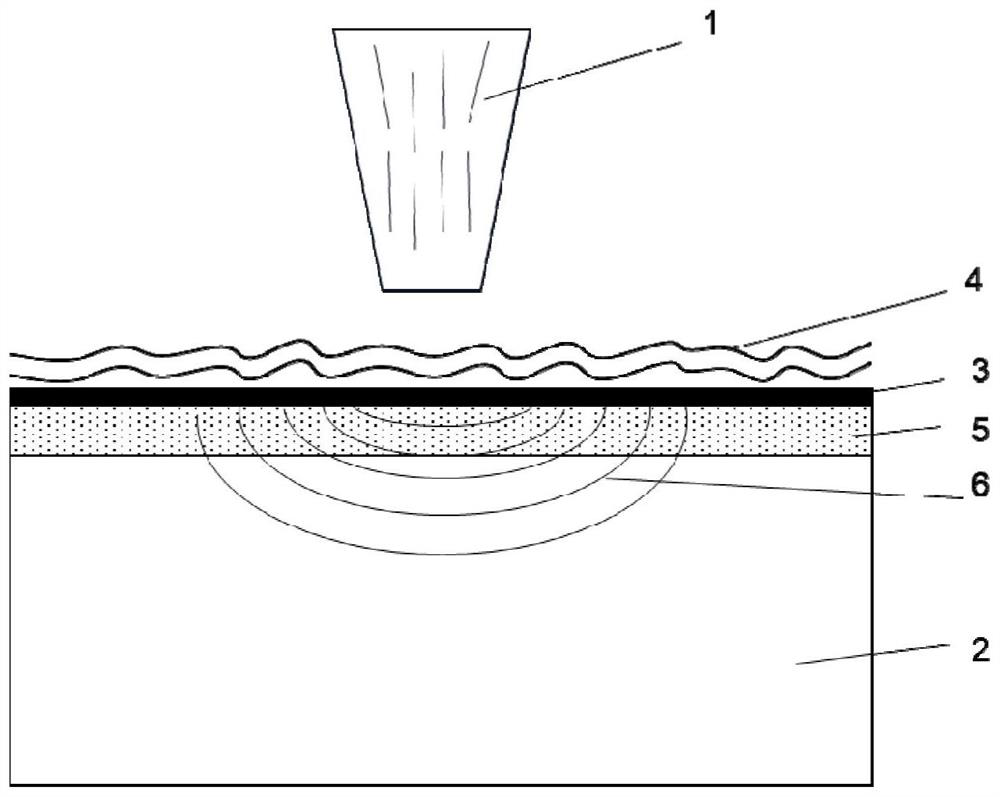

[0039] The peeled coating of the present application is prepared by cold spraying method. The preparation method of the coating includes: using inert gas as the accelerating gas, the gas pressure is 0.5-5MPa, the gas temperature is 100-1000°C, and the moving speed of the spray gun is 10-1000mm / s, the sprayed powder particle size is 10-70μm. In some embodiments of the present application, the accelerating gas is nitrogen or helium. The coating prepared by the preparation method is well bonded to the metal substrate and is not easily peeled off by mechanical means. Therefore, the coating is more suitable for removing the coating on the surface of the substrate by the stripping method provided in the present application. It should be noted that the method for stripping and removing the coating on the surface of the substrate provided in this application is also applicable to coatings prepared by other preparation methods, not limited to the cold spray preparation process.

[0...

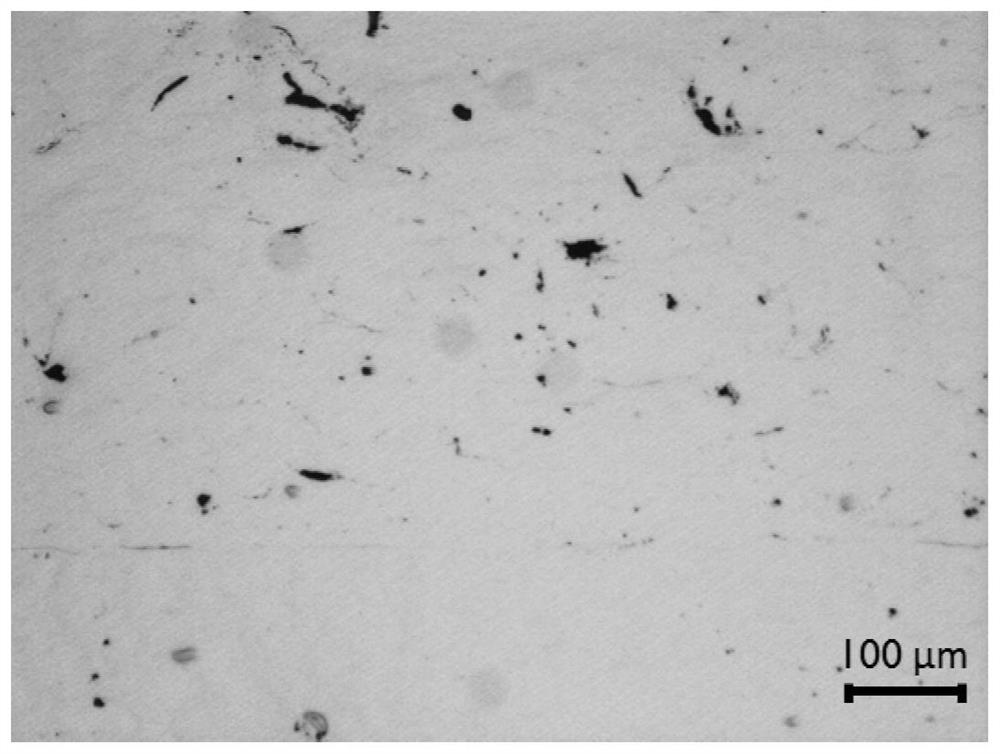

Embodiment 1

[0050] The present embodiment provides a method for stripping and removing the substrate surface coating, including:

[0051] Select the IN718 substrate with IN718 coating, the coating is made by cold spraying, and the thickness of the coating is 1.5mm. A black adhesive tape is set on the surface of the coating as a protective layer, and K9 glass is set on the surface of the protective layer as a constraining layer.

[0052] A laser is used to align the coating, wherein the distance between the source of the laser beam and the coating is 0.2 mm. The laser beam is irradiated vertically on the surface of the coating.

[0053] Turn on the laser and scan the surface of the coating with laser irradiation. Among them, the energy of the laser beam is 10J, the frequency is 10Hz, and the energy density is 8GW / cm 2 . The spot of the laser beam used in the embodiment of the present application is circular, and the laser beam scans row by row or column by row. In order to make the las...

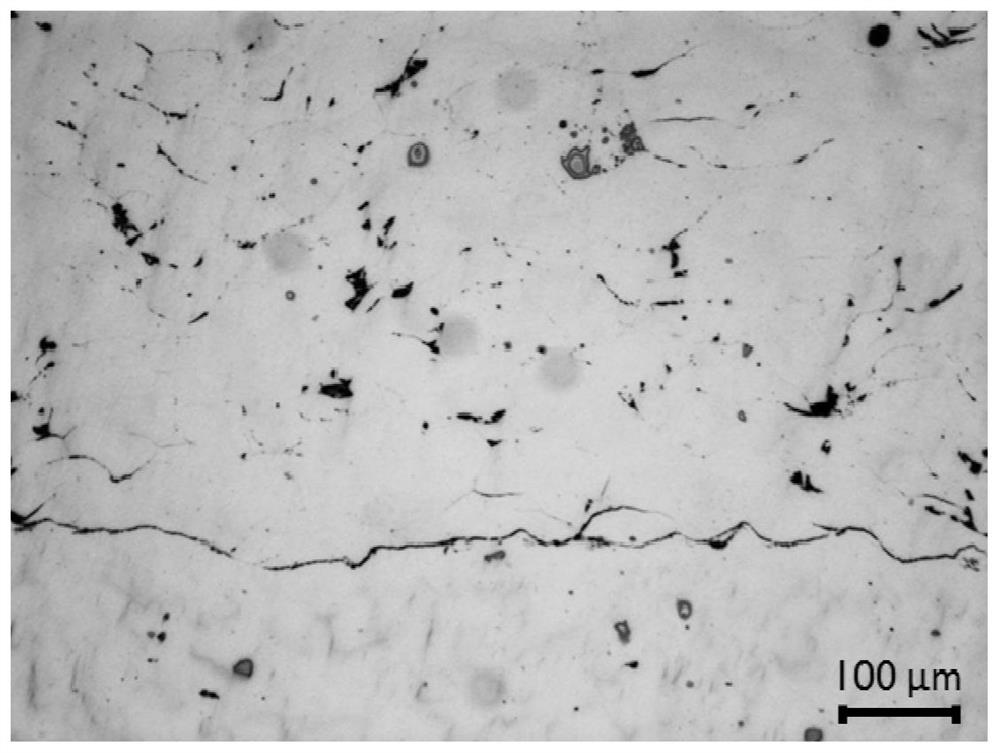

Embodiment 2

[0057] The present embodiment provides a method for stripping and removing the substrate surface coating, comprising:

[0058] Select with Ti 6 Al 4 V-coated Ti 6 Al 4 V substrate, the coating is made by cold spraying, the thickness of the coating is 0.5mm. A black adhesive tape is set on the surface of the coating as a protective layer, and a transparent water layer is set on the surface of the protective layer as a constraint layer.

[0059] A laser is used to align the coating, wherein the distance between the source of the laser beam and the coating is 0.2 mm. The laser beam is irradiated vertically on the surface of the coating.

[0060] Turn on the laser and scan the surface of the coating with laser irradiation. Among them, the energy of the laser beam is 10J, the frequency is 4Hz, and the energy density is 4.43Gw / cm 2 . The spot of the laser beam used in the embodiment of the present application is circular, and the laser beam scans row by row or column by row....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com