Horizontal brush roll forming machine

A technology of forming machine and brush roller, applied in metal processing equipment, grinding device, grinding/polishing equipment, etc., can solve the problems of difficult installation and lifting, high investment cost, unsafe operation, etc., and shorten auxiliary work. Time, easy installation, high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

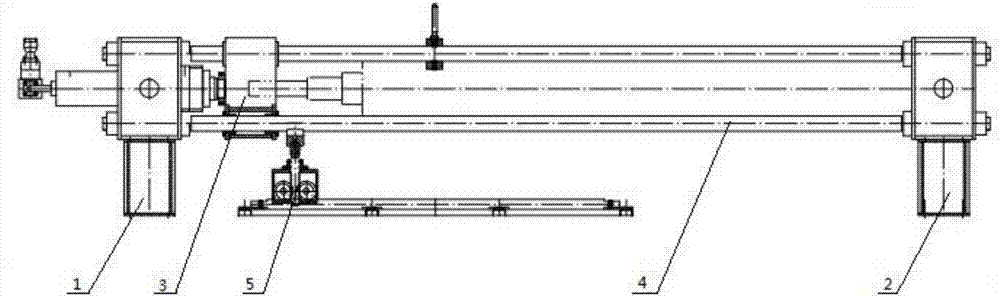

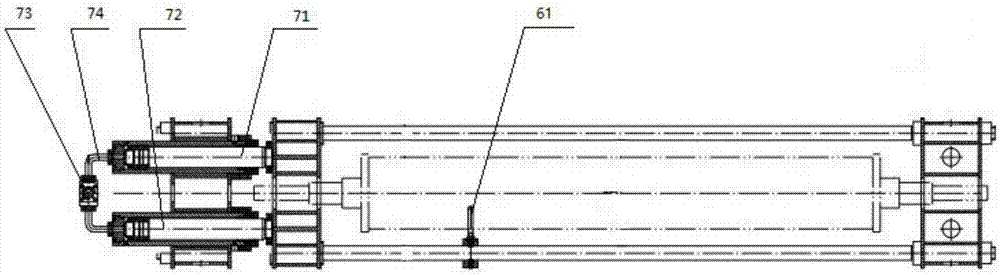

[0058] combine Figures 1 to 5 As shown, the present invention provides a horizontal brush roll forming machine, which includes a frame, a mobile platform 3, a guide assembly 4, a hydraulic system 7, a mobile trolley 5, an anti-tension mechanism 6 and a stroke limiting device.

[0059] Further, the guide assembly 4 is fixedly connected to the frame, the mobile platform 3 can move horizontally along the guide assembly 4, the hydraulic system 7 is used to drive the movement of the mobile platform 3, and the stroke limit The device 8 is used to limit the movement position of the mobile platform 3 .

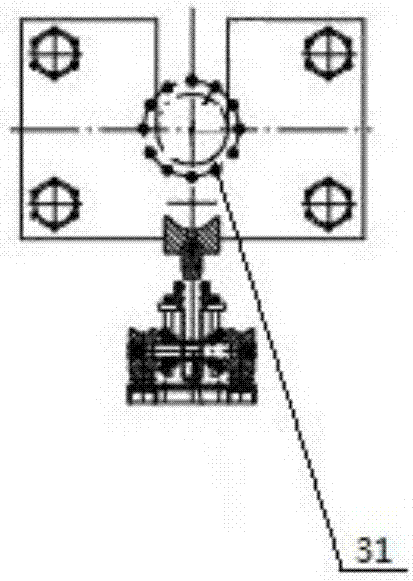

[0060] Further, the mobile trolley 5 is used to support the inner shaft of the roller, so as to facilitate the feeding of the inner shaft of the roller.

[0061] Further, the anti-tension mechanism 6 is used to restrain the expansion of the material ring.

[0062] Specifically, the frame includes a frame I (1) and a frame II (2), and the guide assembly 4 is several guide posts.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com