A combination fixing device for high temperature pipelines

A technology for fixing devices and pipelines, which is applied in pipeline protection, pipeline support, and pipeline protection through heat insulation, etc. It can solve problems such as support failure, fixed support failure, and large thermal stress, so as to improve the ability to withstand moments and improve reliability. and safety, the effect of reducing stress levels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with accompanying drawing:

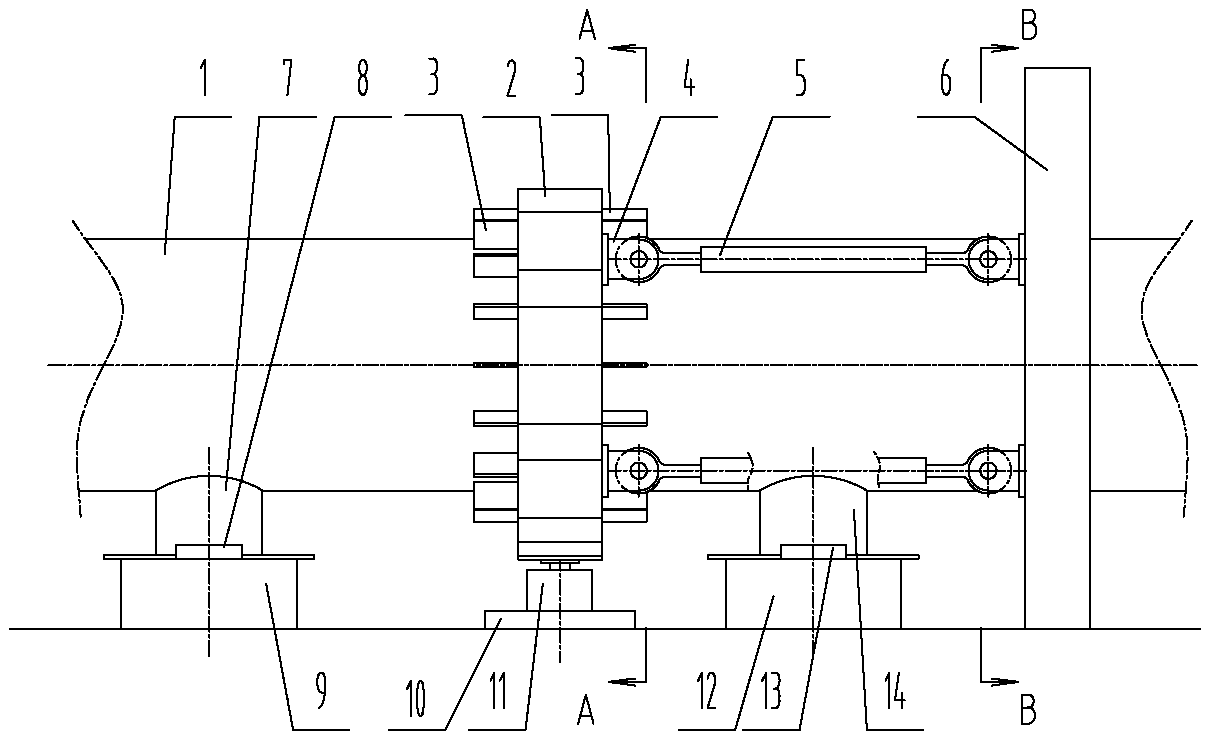

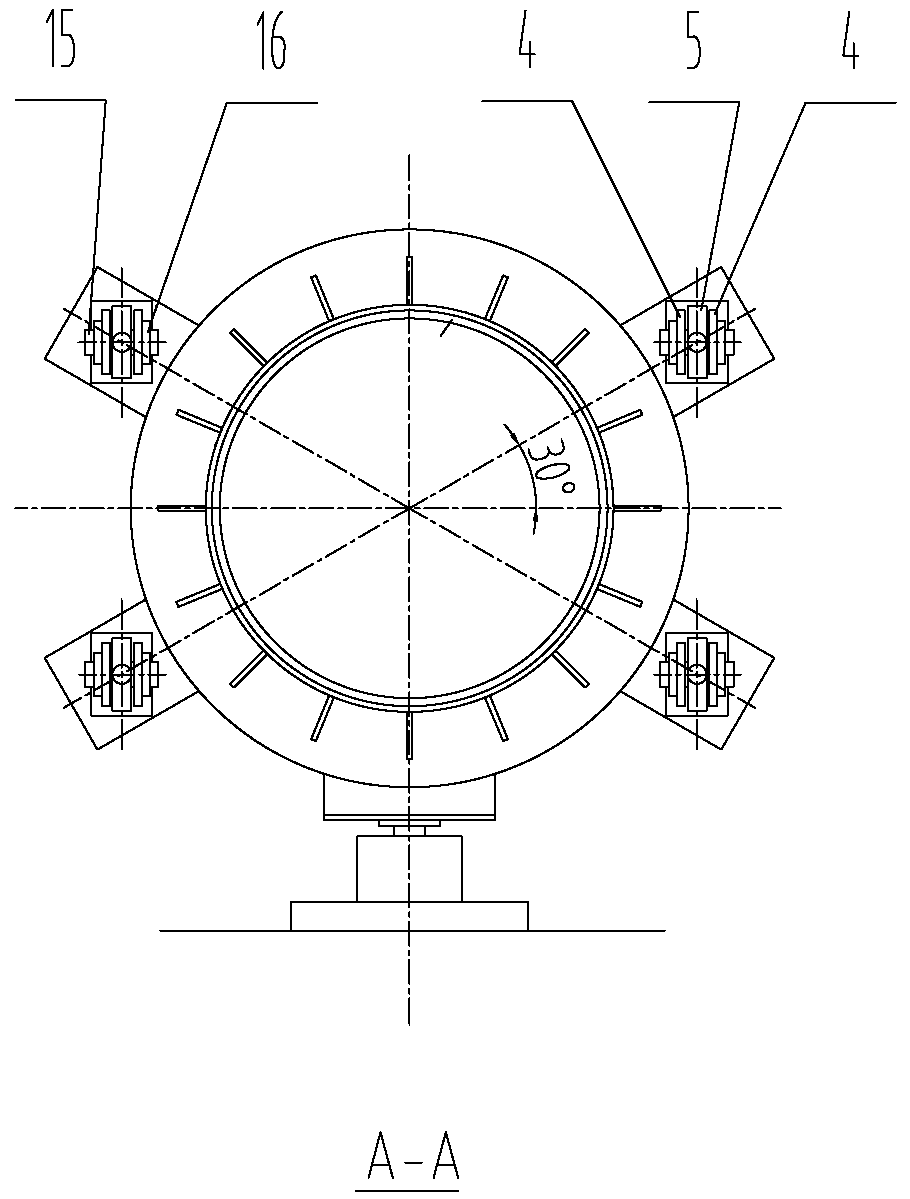

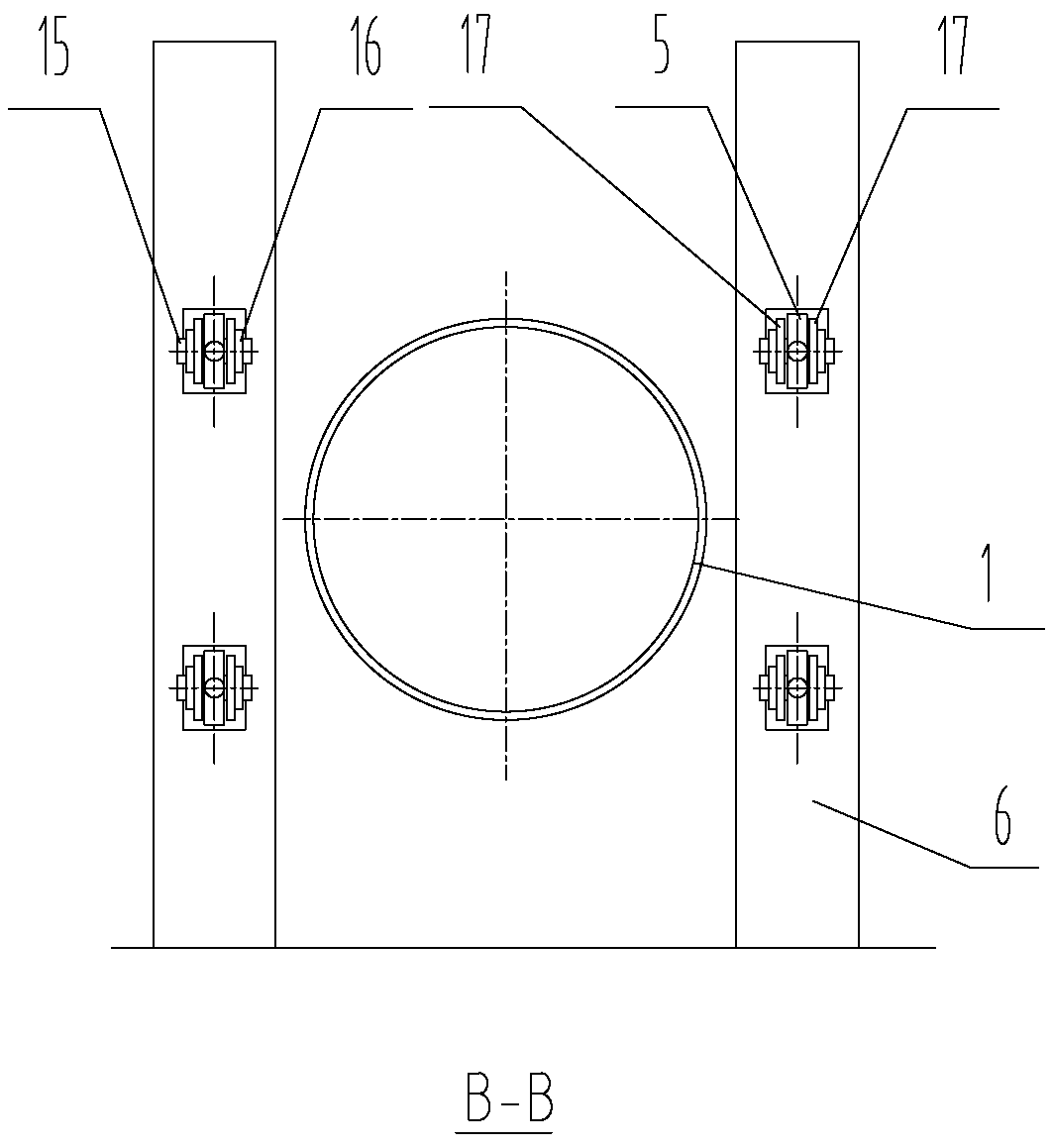

[0030] Such as figure 1 As shown, the present invention includes a pipeline 1, and a floating structure 2 is arranged outside the place where the pipeline 1 needs to be fixed. The floating structure 2 is composed of two box-type semi-rings with a rectangular cross section, and the inside of the rectangular frame of the two semi-rings is filled along the circumference. The heat insulation material wrapped by steel wire is connected by bolts and nuts to form an integral ring. The floating structure 2 is set on the pipe 1. There is a space between the inner diameter of the floating structure 2 and the outer diameter of the pipe 1 that is greater than the radial expansion of the pipe 1. gap. Weld evenly distributed baffles 3 along the circumference of the pipeline 1. If the pipeline 1 is only under one-way force during system operation, the baffles 3 are only arranged on the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com