High-damp rubber supporting seat compositing high-strength fine steel wire mesh with reinforced steel fibers

A high-damping rubber layer and rubber bearing technology, applied in bridge parts, bridges, buildings, etc., can solve problems such as insufficient shear capacity of high-damping rubber bearings, and achieve optimal internal stress distribution, light weight, and weight reduction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

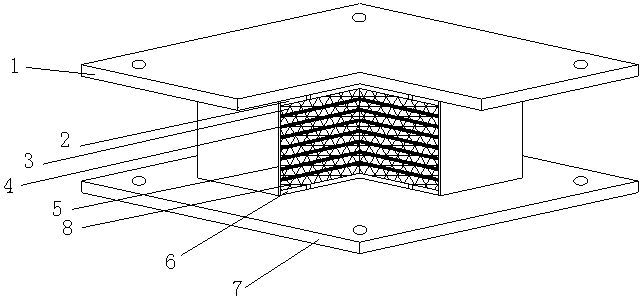

[0028] Example 1: A high-strength fine-density steel wire mesh reinforced steel fiber composite high-damping rubber bearing, consisting of an upper connecting steel plate 1, an upper sealing plate 2, a high-damping rubber layer 3, a high-strength fine-density steel mesh layer 4, a rubber protection layer 5, and a lower The sealing plate 6, the lower connecting steel plate 7 and the steel fiber 8 are composed. The high-strength fine-density steel wire mesh layer 4 is fully bonded and vulcanized to form a reliable bond with the high-damping rubber layer 3, and the rubber protective layer 2 is wrapped outside the high-damping rubber layer 3, and the high-strength steel wire close to the rubber protective layer can be used as a hook; The upper sealing plate 2 and the lower sealing plate 6 are respectively bonded to the upper and lower surfaces of the high damping rubber layer, and the upper and lower sealing plates are connected to the upper and lower connecting steel plates throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com