Painting device, painting arrangement, method for painting a curved surface of an object, and use of an inkjet device for painting an aircraft

a technology for painting devices and aircraft, which is applied in the direction of coatings, typewriters, printing, etc., can solve the problems of affecting the appearance of aircraft, and requiring a complex and expensive suction of solvents and aerosols, so as to achieve the effect of painting aircraft in a very short time, low cost and few human resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

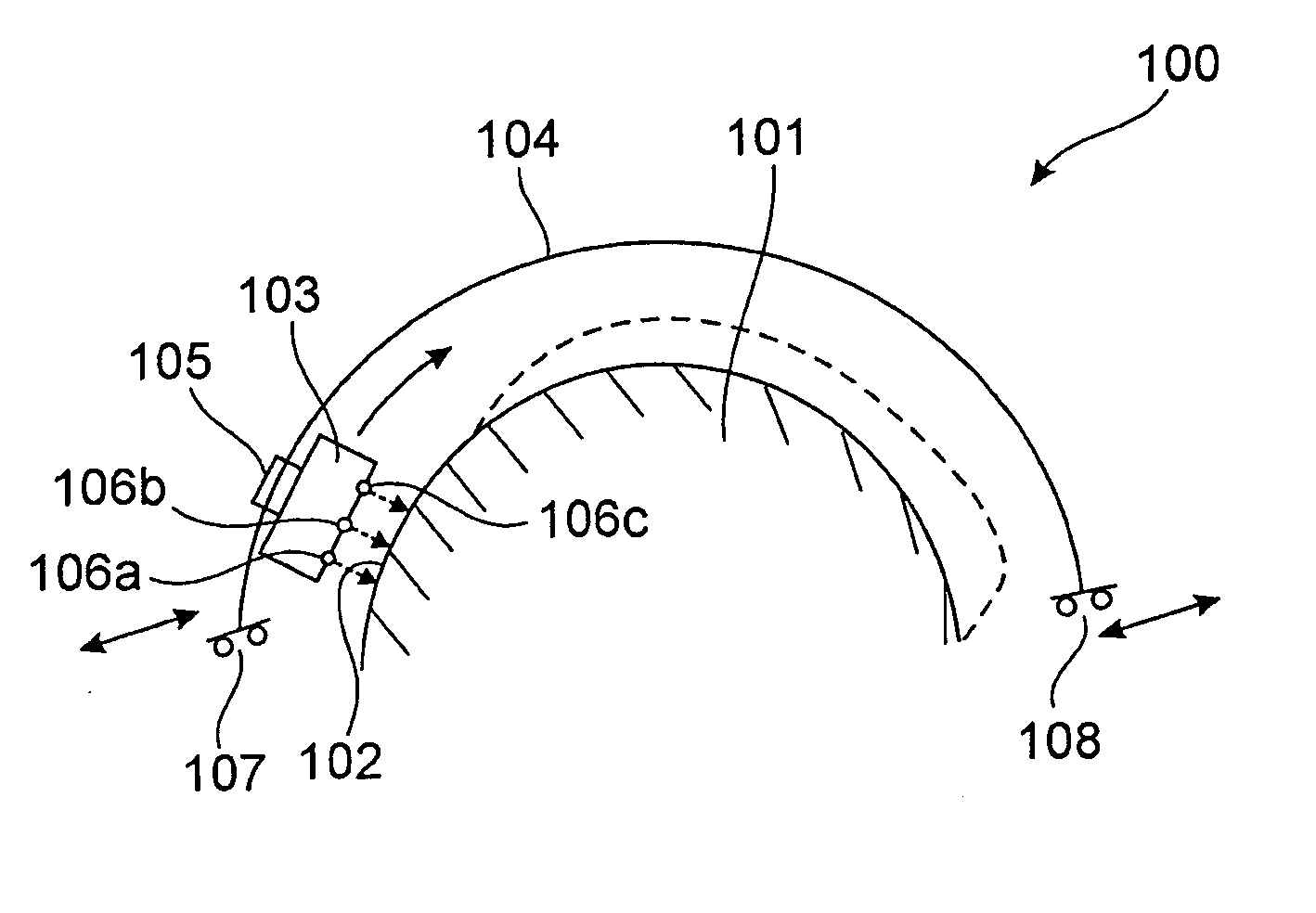

[0064] Below, with reference to FIG. 1, a painting arrangement 100 according to the invention is described.

[0065] The painting arrangement 100 comprises a fuselage 101 with a curved surface 102 to be painted and a painting device for painting the curved surface 102 of the fuselage 101.

[0066] The painting device of FIG. 1 comprises an inkjet device 103, i.e. an inkjet printing unit which is equipped for ejecting paint material. The inkjet device 103 comprises a first paint jet 106a for ejecting red paint,. a second paint jet 106b for ejecting yellow paint, and a third paint jet 106c for ejecting blue paint.

[0067] Furthermore, the painting device comprises a travelling element 105 and a semicircular guide rail 104, along which the travelling element 105 is movably attached. Thus the travelling element 105 can be moved along the guide rail 104, which according to FIG. 1 is semicircular in shape, so as to be able to scan different surface regions of the curved fuselage 101, or to prov...

second embodiment

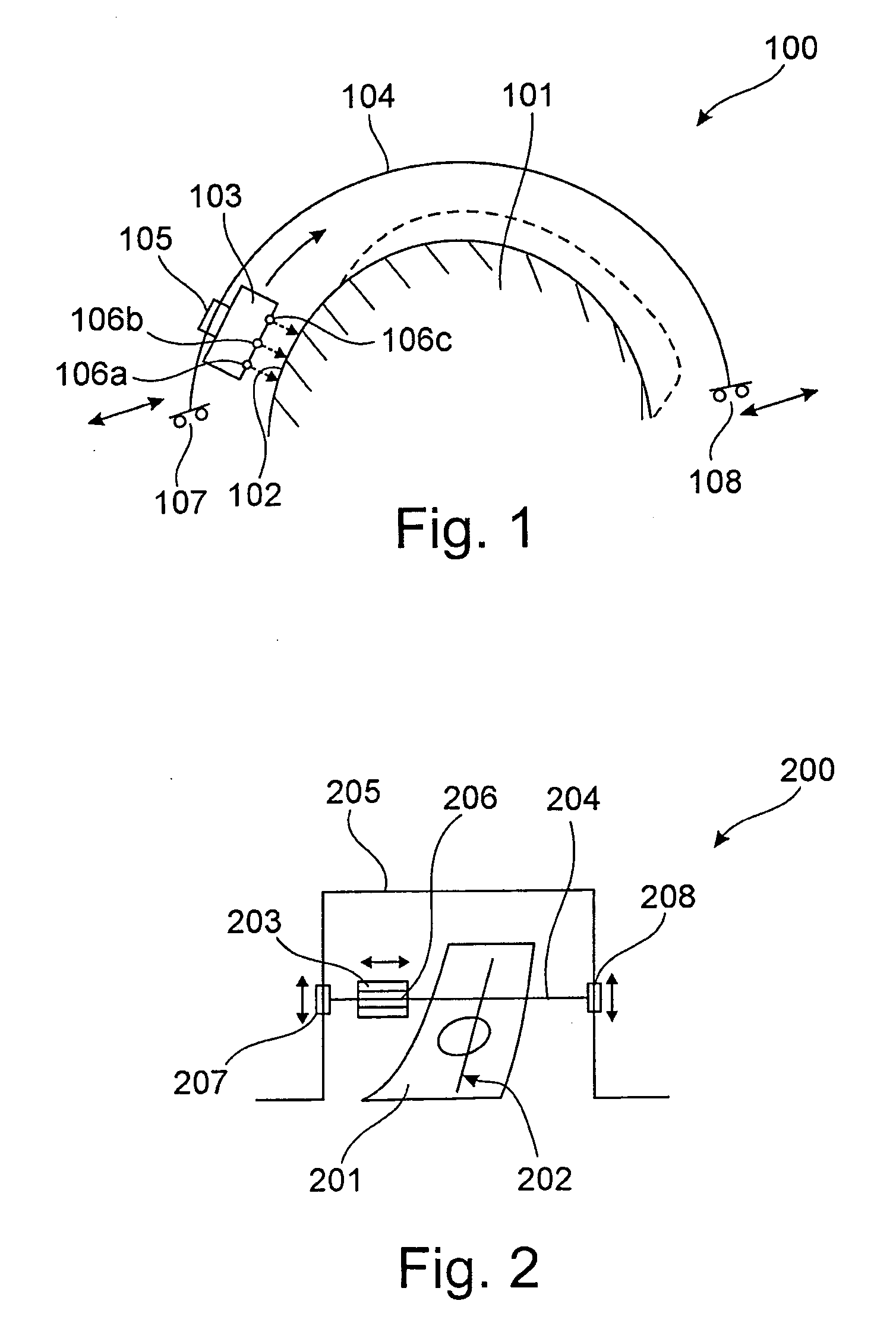

[0072] Below, with reference to FIG. 2 a painting arrangement 200 according to the invention is described.

[0073] The painting arrangement 200 is arranged for painting a curved surface 202 to be painted of a rudder unit 201 of an aircraft. To this effect an inkjet device 203 comprising paint jets (not shown in FIG. 2) is moved along the curved surface 202 to be painted, and paint materials of different colours are ejected from the paint jets so as to apply a desired texture to the curved surface 202 to be painted. In a direction that is horizontal according to FIG. 2 the inkjet device can be slid along a first guide rail 204 by means of a first travelling element 206. Furthermore, the first guide rail 204 in two edge sections comprises a second travelling element 207 and a third travelling element 208, respectively which are attached to a second guide rail 205 so as to be slidable in vertical direction according to FIG. 2. Thus, by sliding the travelling elements 206 to 208 along the...

third embodiment

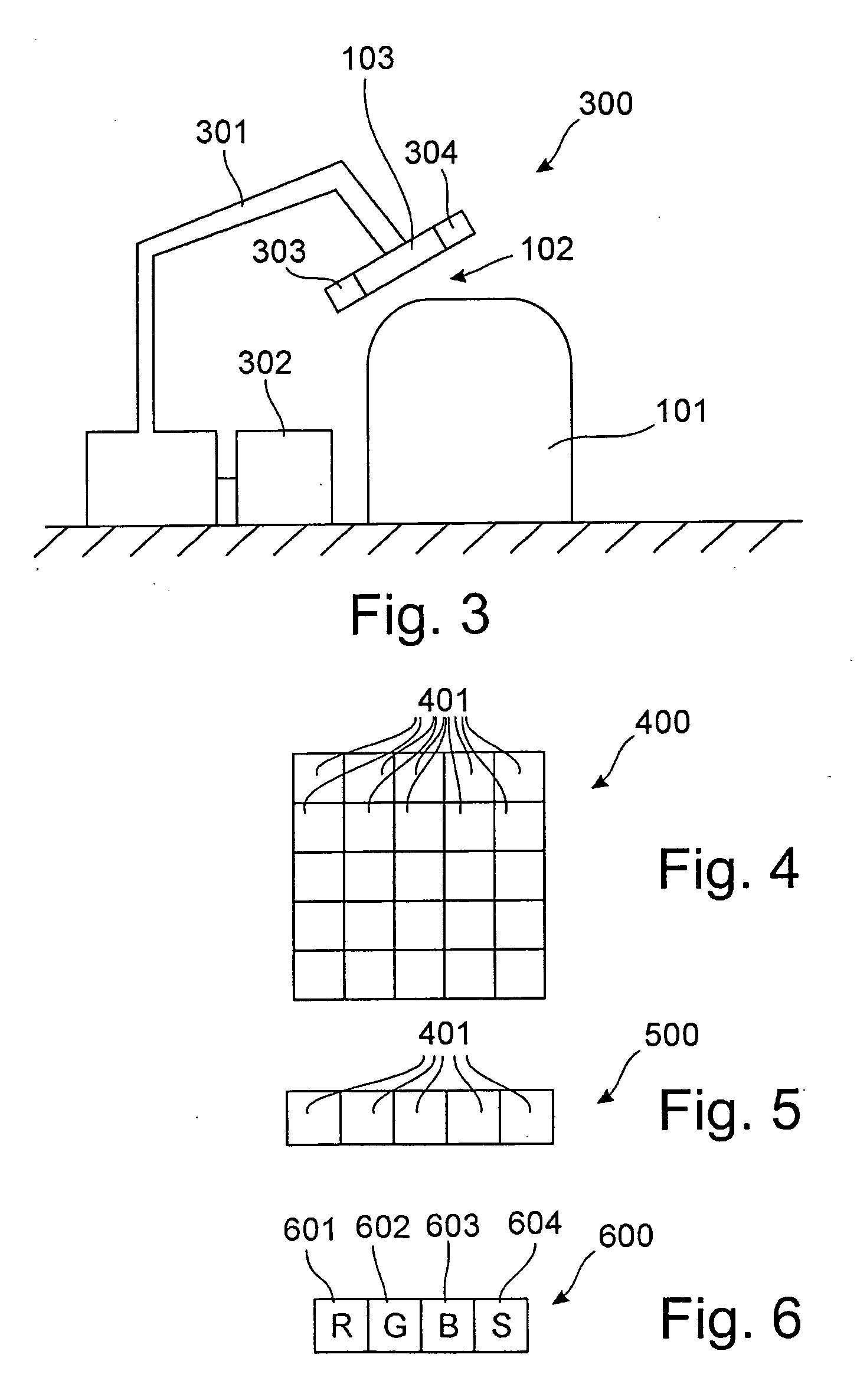

[0075] Below, with reference to FIG. 3 a painting arrangement 300. according to the invention is described.

[0076] The painting arrangement 300 is equipped for painting a curved surface region 102, to be painted, of a fuselage 101 shown in cross section in FIG. 3. To this purpose the painting arrangement 300 comprises an inkjet device 103 with a plurality of spray jets by means of which the surface 102 to be painted can be covered with paint. The inkjet device 103 is attached to a guide robot 301 which can be controlled by means of a control computer 302. The guide robot 301 can guide the painting arrangement 300 along the surface region 102 to be painted so that the paint jets of the inkjet device 103 scan the surface 102 to be painted and cover said surface with paint according to a predefinable sequence.

[0077] The control computer 302 controls not only the timing of the ejection of paint from each of the paint jets of the inkjet device 103 but also mechanical guidance of the inkj...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com