Low-temperature ceramic permeable bricks and production method thereof

A technology of low-temperature ceramics and production methods, applied in the field of building materials, can solve problems such as inability to absorb precipitation, environmental pollution, and house collapse, and achieve the effects of high waste utilization rate, no environmental pollution, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

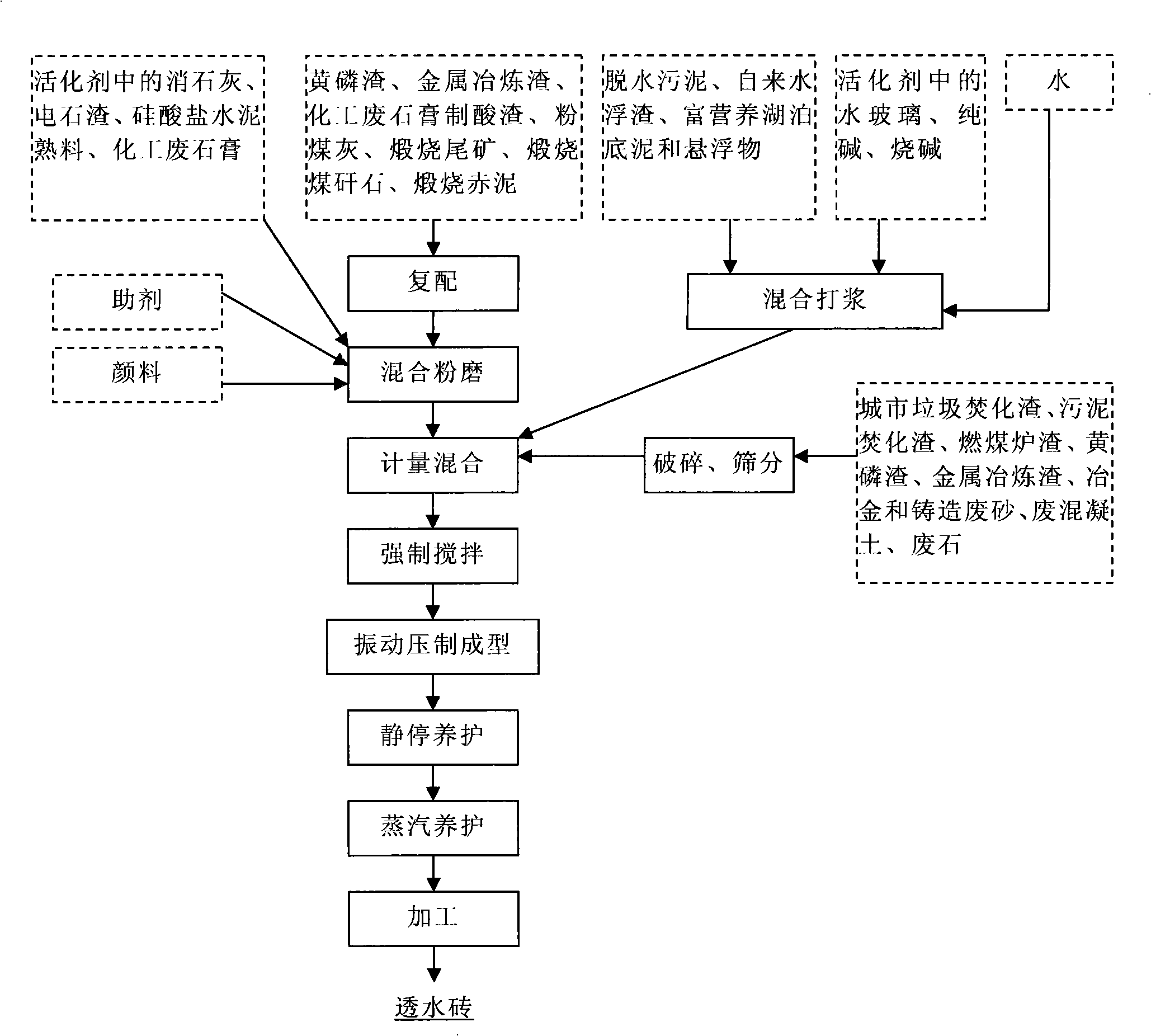

Method used

Image

Examples

Embodiment 1

[0040] 1) Formula composition (substance measurement units are parts by mass):

[0041] (1) Cementitious material: 70 parts of yellow phosphorus slag, 20 parts of fly ash, 10 parts of blast furnace slag;

[0042] (2) Aggregate composition: 150 parts of yellow phosphorus slag, 50 parts of sodium silicate waste sand;

[0043] (3) Porogen: 12 parts of dewatered sludge, 10 parts of bottom mud of Dianchi Lake;

[0044] (4) Activator: 7 parts of water glass, 0.5 part of sodium carbonate, 0.5 part of caustic soda, 2 parts of desulfurized gypsum, 3 parts of clinker;

[0045] (5) Additives: 1.0 parts of calcium lignosulfonate, 0.4 parts of sodium humate, 0.5 parts of borax, 0.3 parts of sodium phosphate, 0.5 parts of calcium fluoride, 0.1 parts of sodium fluoride, and 0.2 parts of calcium fluorosilicate;

[0046] (6) Pigment: 5 parts of iron red;

[0047] (7) Water: 20 parts of red mud attached liquid.

[0048] 2) Process:

[0049] Measure yellow phosphorus slag, fly ash, sodium c...

Embodiment 2

[0054] 1) Formula composition (substance measurement units are parts by mass):

[0055] (1) Cementitious material: 40 parts of blast furnace slag, 20 parts of fly ash, 20 parts of calcined red mud, 20 parts of calcined alumina tailings;

[0056] (2) Aggregate composition: 100 parts of cinder, 700 parts of waste rock;

[0057] (3) porogen: 40 parts of tap water scum (moisture content 80%);

[0058] (4) Activator: 30 parts of water glass, 6 parts of caustic soda, 5 parts of clinker;

[0059] (5) Additives: 1.0 part of naphthalenesulfonate, 0.1 part of sodium phosphate;

[0060] (6) Pigment: 0.1 part of iron red;

[0061] (7) Water: no addition.

[0062] 2) Process:

[0063] Measure blast furnace slag, fly ash, calcined red mud, calcined alumina tailings, clinker, naphthalene sulfonate, sodium phosphate, and iron red according to the formula, and blend and grind them into a powder with a particle size of less than 0.08mm accounting for 92%;

[0064] Aggregate preparation: C...

Embodiment 3

[0068] 1) Formula composition (substance measurement units are parts by mass):

[0069] (1) Cementitious material: 40 parts of thermal manganese slag, 20 parts of phosphogypsum acid slag, 20 parts of calcined coal gangue, and 20 parts of steel slag;

[0070] (2) Aggregate composition: 50 parts of municipal waste incineration slag, 50 parts of sludge incineration slag, 100 parts of copper slag, 100 parts of waste concrete, 100 parts of waste brick;

[0071] (3) porogen: 40 parts of Dianchi cyanobacteria residue (water content 95%);

[0072] (4) Activator: 5 parts of soda ash, 15 parts of slaked lime, 10 parts of carbide slag, 3 parts of Portland cement clinker, and 3 parts of phosphogypsum;

[0073] (5) Additives: 0.5 parts of naphthalenesulfonate, 0.75 parts of sodium phosphate;

[0074] (6) Pigments: 1.5 parts of iron black, 3.0 parts of iron yellow, 2.0 parts of chrome yellow, 0.5 parts of iron blue;

[0075] (7) Water: Contains 1 part of condensed water for steam curing ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com