Preparation method of polyester resin used in outdoor weatherable powder paint

A powder coating and polyester resin technology, applied in powder coatings, polyester coatings, coatings, etc., can solve problems such as no method and process, and achieve the effects of reducing production process costs, excellent leveling, and reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

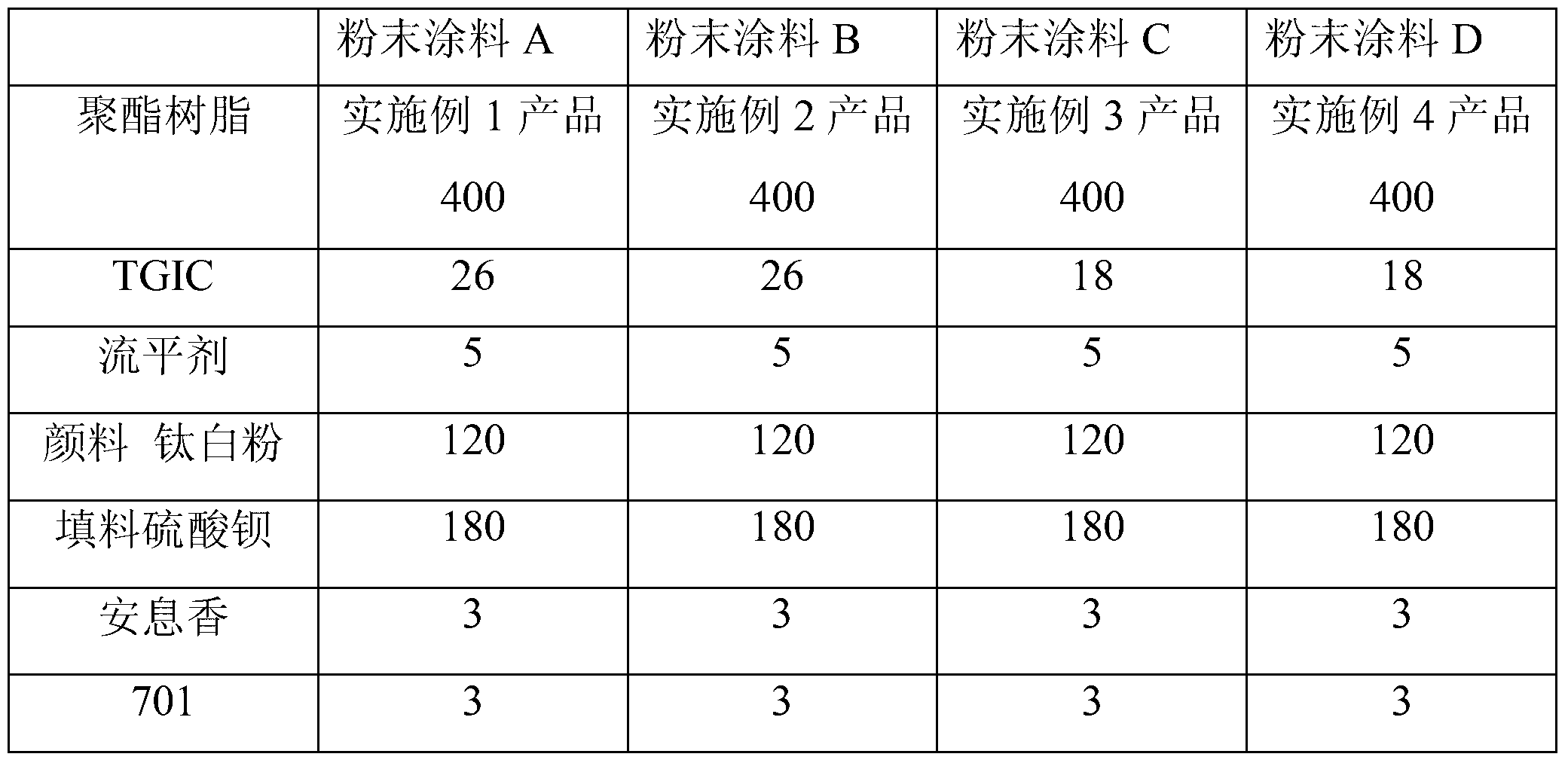

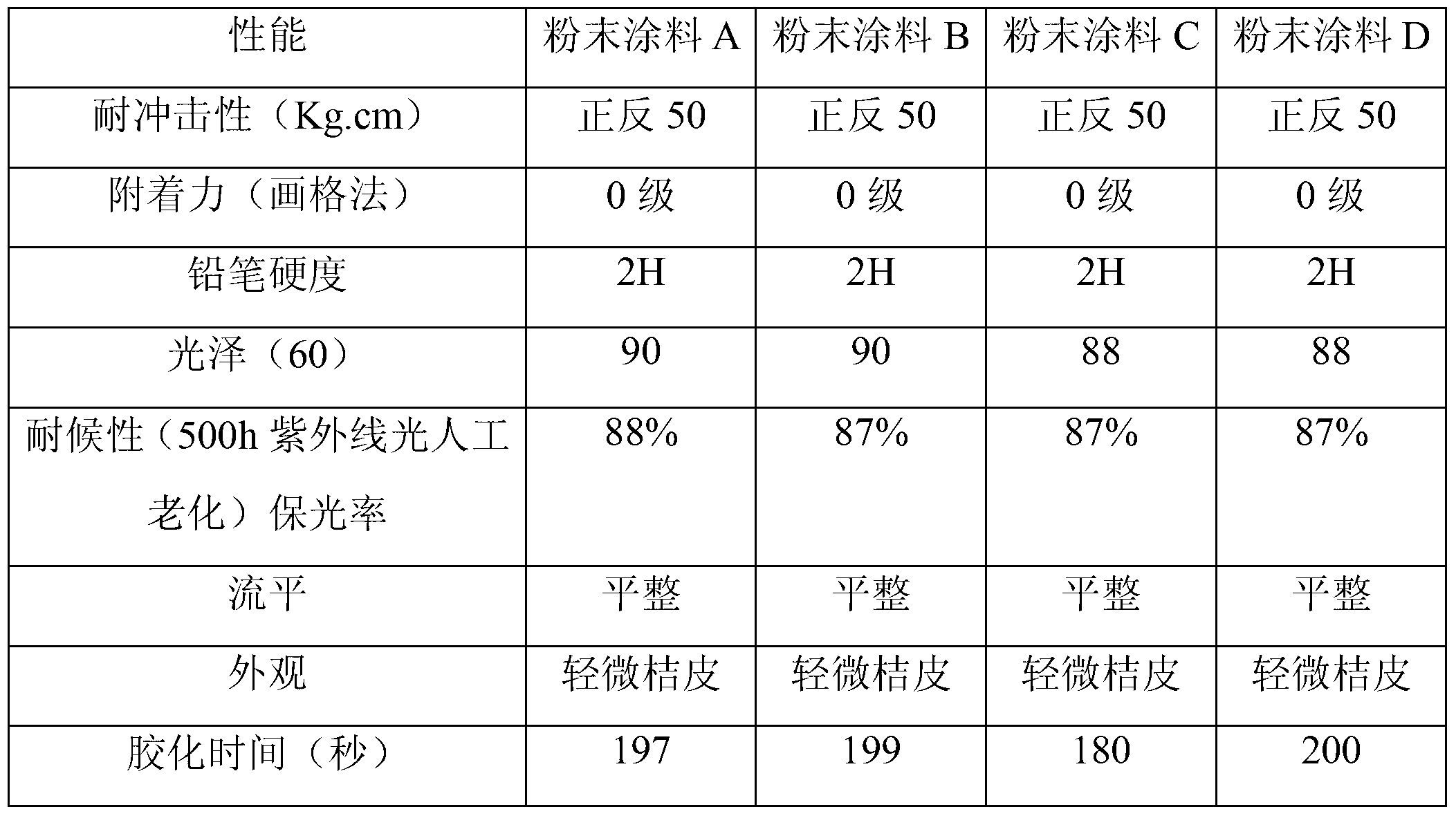

[0038] The polyester resin obtained in Example 1 can meet the standard general formulations of various properties of weather-resistant powder coatings. The present invention uses PET polyester waste to synthesize various comprehensive properties of polyester resins and use this formulation as a reference for comparison.

[0039] According to the formula requirement of embodiment 1 in table 1, in the 1500 liters of reactors that are equipped with agitator and precision fractionation column, add esterification catalyst monobutyltin oxide, neopentyl glycol, trimethylol propane successively, be warming up to Keep the stirrer running at 100°C, with a rotation speed of 1r~50r / min, then add terephthalic acid, adipic acid, and triphenyl phosphite in sequence, protect with nitrogen, continue to heat up the reaction, and start to form esters at 180°C±5°C Melt water, separate the system in time, control the temperature at the top of the process tower to be stable within 105°C, further rai...

Embodiment 2

[0041] Use PET bottle flakes for short fiber or long fiber as raw material, after washing and removing impurities, crush it to 10mm~40mm for later use;

[0042]The injection temperature of neopentyl glycol is around the boiling point of neopentyl glycol at 190°C to 220°C. After preheating, the neopentyl glycol is injected by a high temperature resistant pump with pressure at a pressure of 0.1Mpa to 10Mpa. The injection of high-pressure neopentyl glycol vapor and liquid is used to resist the high-resistance pressure generated during the extrusion process. The speed is 1000Kg per hour. The total residence time of the material in the twin-screw is 1-30min, and the screw speed is 5r ~30r / min.

[0043] Under the above conditions, PET gets a rapid alcohol degradation reaction. The neopentyl glycol injected through the screw at high temperature is 50.00Kg, and the mixed melt that has undergone preliminary alcohol degradation is extruded at a speed of 1000Kg per hour. In the 1500-lit...

Embodiment 3

[0047] Use short fiber or long fiber PET bottle flakes as raw materials, and crush the washed and impurity-removed PET raw materials to 10mm-40mm for later use;

[0048] The injection temperature of neopentyl glycol is around the boiling point of neopentyl glycol at 190°C to 220°C. After preheating, the neopentyl glycol is injected by a high temperature resistant pump with pressure at a pressure of 0.1Mpa to 10Mpa. The injection of high-pressure neopentyl glycol vapor and liquid is used to resist the high-resistance pressure generated during the extrusion process. The speed of extrusion is 1000Kg per hour. The total residence time of the material in the twin-screw is 1-30min, and the screw speed is 5r- 30r / min.

[0049] Under the above-mentioned conditions, PET obtains fast alcohol degradation reaction, and the addition of embodiment 3 PET is 628.75Kg, and the neopentyl glycol that injects by screw high temperature is 50.00Kg, the mixed melt that will be through initial alcoho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com