Phosphorus-containing catalyst composition and hydroformylation process using the same

A hydroformylation and catalyst technology, applied in the field of hydroformylation, can solve the problems of catalyst deactivation, expensive catalyst and the like, and achieve the effect of high catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~11

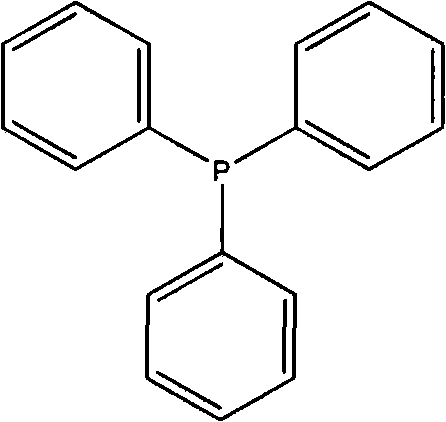

[0060] use acetylacetonate carbonyltriphenylphosphine rhodium (Rh(AcAc)(CO)(TPP), ROPAC) catalyst, triphenylphosphine compound, monodentate phosphine compound and monodentate phosphine oxide compound Propylene hydroformylation reaction

[0061] 0.010 mg of ROPAC (0.390 mmol) as catalyst; TPP as triphenylphosphine compound L1; TMTP, BDPP, TCHP, TBP, DPMPP, TMSTP, DPPTP or TDMPP as monodentate phosphine compound L2; and TMTPO, BDPPO, TCHPO, DPMPPO, TMSTPO, DPPTPO or TDMPPO of the phosphine oxide compound L3 according to the molar ratio (L / Rh) of the ligand to the metal (Rh) of the ROPAC described in Table 1 in a high pressure reactor with a volume of 20 ml Dissolve in toluene solvent so that the total volume of the solution is 10 ml, then add. Propylene (olefin):CO:H 2 Injected into the above reaction solution, and reacted for 2.5 hours, at this time, the pressure of the reactor was maintained at 8 bar, and stirring was performed at 85°C.

[0062] The catalyzer of above-ment...

Embodiment 12~14

[0069] include acetylacetonate carbonyltriphenylphosphine rhodium (Rh(AcAc)(CO)(TPP), ROPAC) catalyst, triphenylphosphine compound, monodentate phosphine compound and monodentate phosphine oxide compound Stability Testing of Catalyst Compositions

[0070] 0.150 mg of ROPAC (0.390 mmol) as a catalyst; 0.3 ml of hexadecane as an internal standard for GC analysis; TPP as a triphenylphosphine compound (L1); TMTP as a monodentate phosphine compound (L2) , TCHP or TMSTP; and TCHPO or TMSTPO as a monodentate phosphine oxide compound in a high-pressure reactor with a volume of 300 ml according to the molar ratio (L / Rh) of ligand to metal (Rh) of ROPAC described in Table 2 below Dissolve in toluene solvent so that the total volume of the resulting solution is 150 ml, and then add. CO:H 2 Gas with a molar ratio of 1:1 was injected into the above solution for aging test. At this time, the pressure in the reactor was maintained at 6 bar and stirred at 105°C. About 30ml of the solution...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com