High-temperature alloy for electronic firework push rod as well as preparation process and application of high-temperature alloy

A high-temperature alloy and fireworks technology, which is applied in the manufacture of tools, metal processing equipment, fireworks, etc., can solve the problems of poor mechanical properties, not suitable for the use of electronic fireworks, and low service life, and achieve the effect of increasing solid solution strengthening elements

Active Publication Date: 2022-04-08

上海康晟航材科技股份有限公司

View PDF13 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0006]

However, the traditional GH3625 superalloy is mainly optimized for high-temperature chemical containers with heat-resistant corrosion requirements or turbine engine hot-end parts with thermal strength requirements, and has not been optimized for the use of electronic fireworks push rods. Under the

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

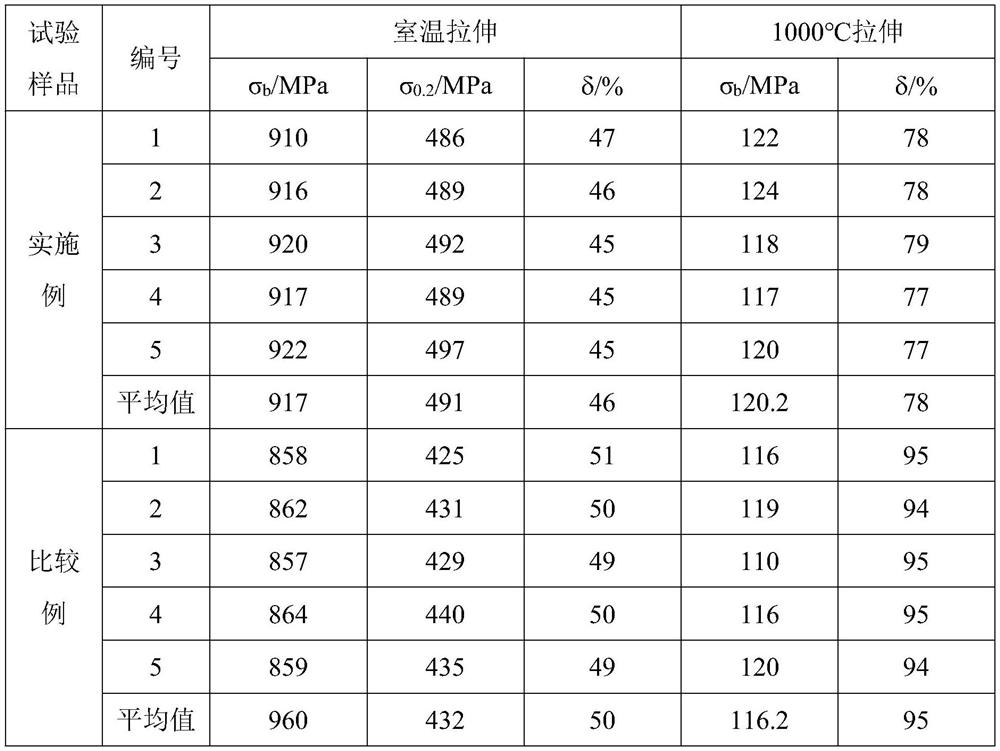

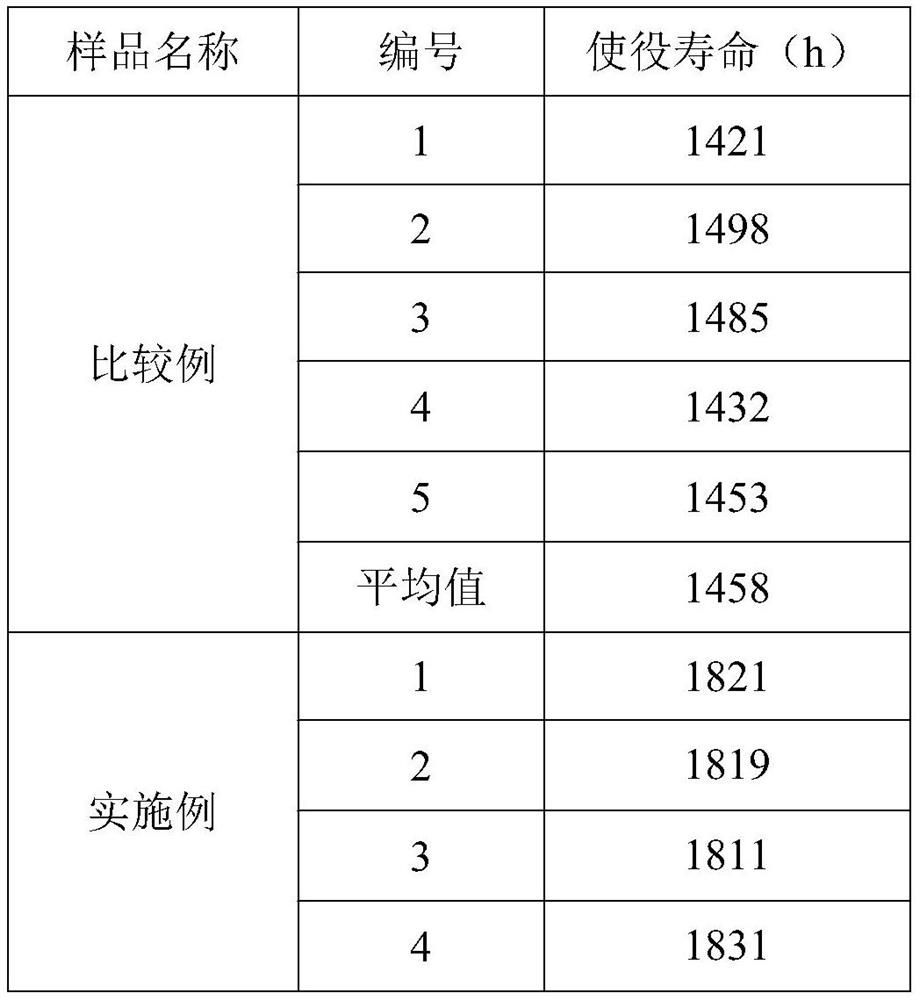

The invention provides a high-temperature alloy for an electronic firework push rod and a preparation process and application of the high-temperature alloy. The high-temperature alloy comprises the following chemical components in percentage by mass: 23-25% of Cr, not more than 1.0% of Fe, 3.15-4.15% of Nb, 10.0-12.0% of Mo, 1.0-2.0% of Co, not more than 0.06% of C, not more than 0.5% of Mn, not more than 0.5% of Si, not more than 0.015% of S, not more than 0.015% of P, not more than 0.07% of Cu, not more than 0.4% of Al, not more than 0.4% of Ti and the balance of Ni. The high-temperature alloy for the electronic firework push rod solves the problems of poor high-temperature mechanical property and short service life of the high-temperature alloy in the prior art, has good thermal stability and mechanical property at room temperature and 1100 DEG C, and can be used for the electronic firework push rod.

Description

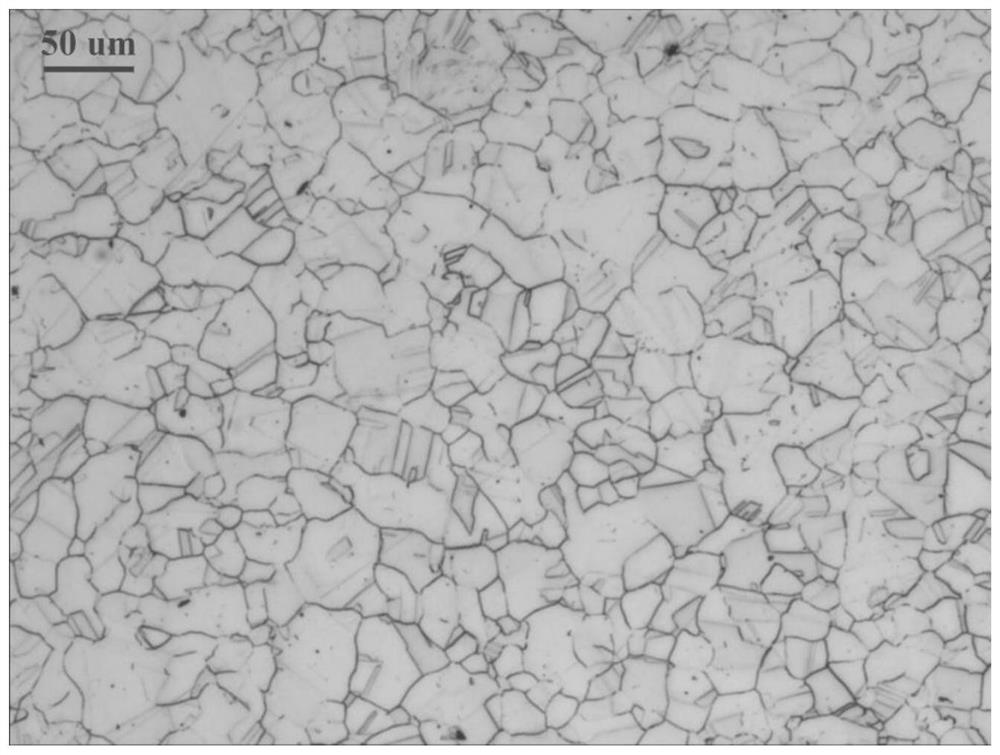

Technical field [0001] The present invention relates to the field of nickel-based high-temperature alloys, and more particularly to a high temperature alloy for electronic fireworks and its preparation processes and applications. Background technique [0002] Under the national ban on fireworks and firecrackers, the fireworks fireworks firecrackers have an extremely large blank market, while electronic fireworks are excellent alternative products. Electronic fireworks belong to environmentally friendly fireworks, and the discharge process does not produce toxic and harmful gases and will not pollute the environment. [0003] Electronic fireworks are generally made of cold flame, using a lower metal powder with a combustion point, a cold light smokeless firework, a cold light smokeless firework, a cold flame full of fire, only 30 ~ 50 ° C, the external temperature is not harmful to the human body, suitable for Stage performances and various styles design. [0004] Although the col...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C22C19/05C22C1/02B22D7/00B22D43/00C21D9/00C22B9/18C22F1/10B21J5/00F42B4/00

CPCY02P10/25

Inventor 汪晶王艳芳汪东

Owner 上海康晟航材科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com