Flame-retardant waterproof material and preparation method thereof

A technology of waterproof materials and liquid materials, applied in fire prevention, building components, heat preservation, etc., can solve the problems of leakage heat preservation effect, easy fire, lowering, etc., achieve long-lasting heat preservation effect, solve fire prevention problems, and improve water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

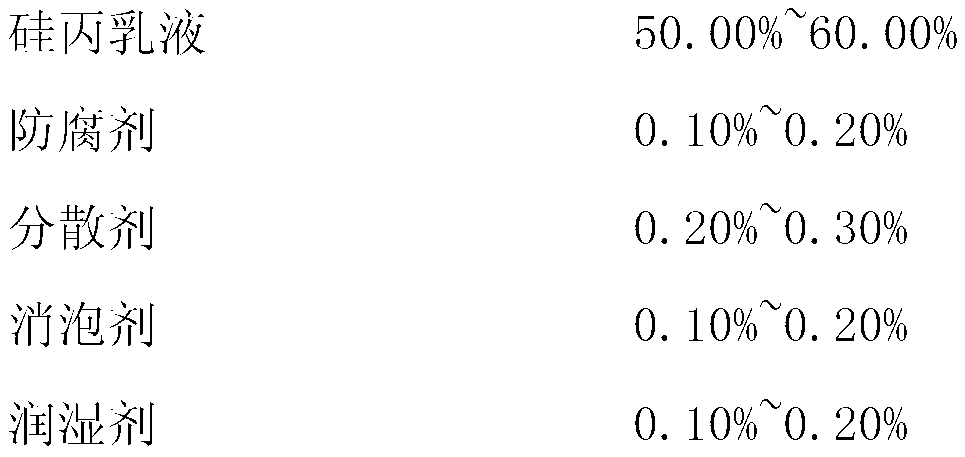

[0037] 1) Liquid material part

[0038] Silicone acrylic emulsion 52.00%;

[0039] Preservative 0.1%;

[0040] Wetting agent 0.1%;

[0041] Dispersant 0.2%;

[0042] Defoamer 0.2%;

[0043] Water 46.30%;

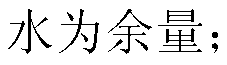

[0044] 2) Powder part:

[0045] Ordinary Portland cement 30.00%;

[0046] High alumina cement 14.77%;

[0047] Quartz sand 53.00%;

[0049] Water reducing agent 0.20%;

[0050] Decabromodiphenylethane 2.00%;

[0051] 3) The weight ratio of each component:

[0052] Liquid material: powder material = 1:3.5.

[0053] Among them, the preservative is concrete preservative, the wetting agent is HSH polyether polyol, the dispersant is sodium polyacrylate, the defoamer is mineral oil, the ordinary Portland cement is 42.5, the high alumina cement is 42.5, and the quartz The sand is 60 mesh, the cellulose ether is hydroxyethyl methyl cellulose ether with a viscosity of 11000, and the water reducing agent is a polycarboxylate water reducing ...

Embodiment 2

[0055] 1) Liquid material part

[0056] Silicone acrylic emulsion 48.00%;

[0057] Preservative 0.2%;

[0058] Dispersant 0.5%;

[0059] Defoamer 0.2%;

[0060] Wetting agent 0.1%

[0061] Water 51.00%;

[0062] 2) Powder part:

[0063] Ordinary Portland cement 33.00%;

[0064]High alumina cement 10.00%;

[0065] Quartz sand 54.77%;

[0066] Cellulose ether 0.03%;

[0067] Polycarboxylate water reducer 0.20%;

[0068] Decabromodiphenylethane 1.00%;

[0069] 3) The weight ratio of each component:

[0070] Liquid material: powder material = 1:3

[0071] Among them, the preservative is concrete preservative, the wetting agent is sorbitol, the dispersing agent is sodium polyacrylate, the defoamer is mineral oil, the ordinary Portland cement type is 42.5, the high alumina cement is 42.5, and the quartz sand is 70 For the purpose, the cellulose ether is hydroxyethyl methyl cellulose ether with a viscosity of 15000, and the water reducing agent is a polycarboxylate water...

Embodiment 3

[0073] 1) Liquid material part

[0074] Silicone acrylic emulsion 57.00%;

[0075] Preservative 0.2%;

[0076] Dispersant 0.1%;

[0077] Silicone defoamer 0.2%;

[0078] Wetting agent 0.1%

[0079] Water 42.40%;

[0080] 2) Powder part:

[0081] Ordinary Portland cement 33.50%;

[0082] High alumina cement 12.00%

[0083] Quartz sand 51.45%;

[0084] Cellulose ether 0.05%;

[0085] Water reducing agent 0.50%;

[0086] Decabromodiphenylethane 2.50%;

[0087] 3) The weight ratio of each component:

[0088] Liquid material: powder material = 1: 2.5

[0089] Among them, the preservative is concrete preservative, the wetting agent is Span, the dispersing agent is sodium polyacrylate, the defoaming agent is polysiloxane, the ordinary Portland cement is 42.5R, the high alumina cement is 42.5, and the quartz The sand is 100 mesh, the cellulose ether is hydroxypropyl methyl cellulose ether with a viscosity of 25000, and the water reducing agent is melamine water reducing a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com