High-flexibility fireproof cable and preparation method thereof

A fire-resistant cable, high flexibility technology, applied in the direction of cable/conductor manufacturing, insulated cables, bendable cables, etc., can solve the problems of weak fire resistance, low flexibility, short service life, etc., and achieve good insulation effect and high flexibility , long service life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

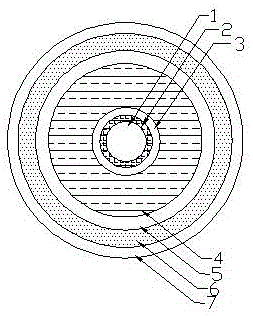

[0060] A method for preparing a highly flexible fireproof cable of this embodiment comprises the following steps:

[0061] (1) Preparation of copper conductor 1: preparation of copper conductor 1: the copper rod is drawn and annealed to obtain annealed copper wire, and at least two annealed copper wires are twisted to form copper conductor 1;

[0062] (2) Prepare the cable core: Wrap the ceramic composite tape 2 on the outer surface of the pretreated copper conductor 1, and then extrude a layer of ceramic polyolefin material on the outer surface of the ceramic composite tape 2 to obtain the cable core;

[0063] (3) Prepare the filling layer 4: fill the outer periphery of the cable core with an organic fireproof mud material to obtain the filling layer 4;

[0064] (4) Wrap mica tape on the outer surface of the filling layer 4 to obtain a mica tape wrapping layer 5;

[0065] (5) Coating the thin copper wire braiding layer 6 on the outer surface of the mica tape wrapping layer 5...

Embodiment 2

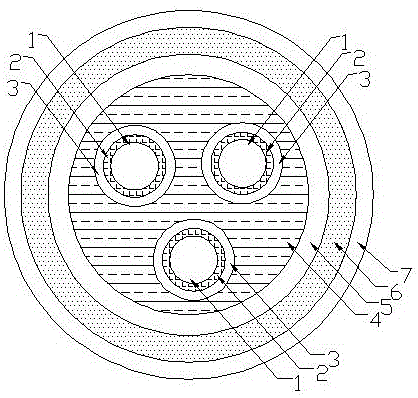

[0081] A method for preparing a highly flexible fireproof cable of this embodiment comprises the following steps:

[0082] (1) Preparation of copper conductor 1: the copper rod is drawn and annealed to obtain annealed copper wire, and at least two annealed copper wires are twisted to form copper conductor 1;

[0083] (2) Prepare the cable core: Wrap the ceramic composite tape 2 on the outer surface of the pretreated copper conductor 1, and then extrude a layer of ceramic polyolefin material on the outer surface of the ceramic composite tape 2 to obtain the cable core;

[0084] (3) Prepare the filling layer 4: fill the outer periphery of the cable core with an organic fireproof mud material to obtain the filling layer 4;

[0085] (4) Wrap mica tape on the outer surface of the filling layer 4 to obtain a mica tape wrapping layer 5;

[0086] (5) Coating the thin copper wire braiding layer 6 on the outer surface of the mica tape wrapping layer 5;

[0087] (6) Cover the sheath la...

Embodiment 3

[0102] The difference between this embodiment and Embodiment 1 or 2 is that the method for preparing copper conductor 1 in this embodiment is specifically: a copper rod with a diameter of 9 mm is subjected to large wire drawing and annealing to obtain an annealed copper wire with a diameter of 2.5 mm. At least seven annealed copper wires are tightly twisted to form a copper conductor 1; steam is used as a protective gas during the large wire drawing process, and antioxidants are added to the cooling water for annealing treatment. The compression coefficient of the tight twisting is ≥ 0.9, and the steam pressure is 2 atmospheres, the annealing temperature is 370°C.

[0103] Preferably, the copper rod is copper material of TU1, and the purity of the copper is more than 99.97%. Specifically, the addition amount of the oxidant is 3% of the total mass of the cooling water, and the oxidant is antioxidant 1010 and antioxidant Agent 168 is a mixture with a mass ratio of 2:1.

[0104]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Dielectric strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com