Thick-thin composite fireproof coating and preparation method thereof

A kind of fireproof coating and composite technology, which is applied in the direction of fireproof coating, coating, cement coating, etc., can solve the problems of few researches on the compounding of fireproof coating, achieve low cost of raw materials and environmental protection, improve fireproof effect, and excellent fireproof and heat insulation performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

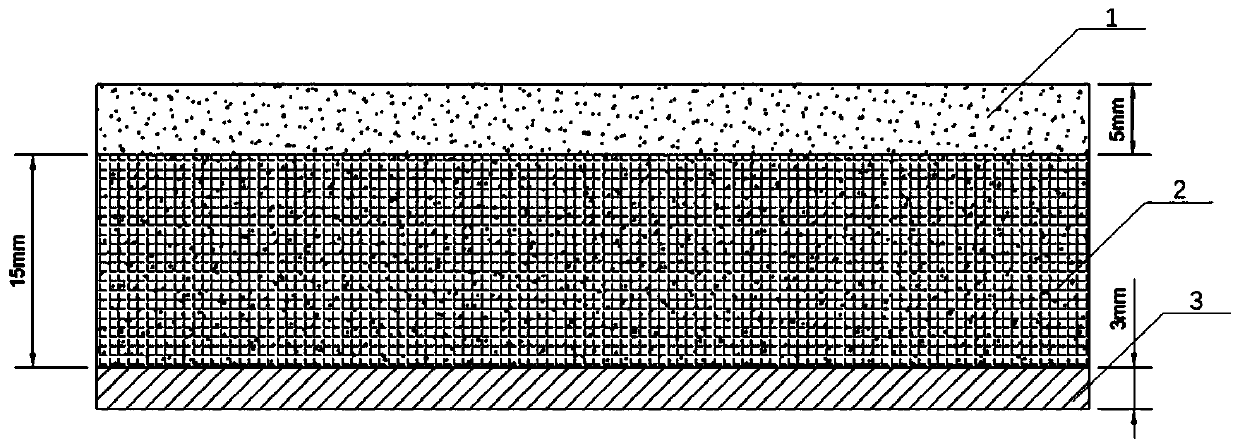

[0033] A kind of thick-thin composite type fireproof coating of this embodiment, its structure schematic diagram is as follows figure 1 shown. Consists of a thick non-intumescent fire protection coating and a thin intumescent fire protection coating on a sheet metal substrate. The base material is Q235 steel plate; the component content of thick non-intumescent fireproof coating (calculated based on 42.5 type Portland cement): 100 parts of 42.5 type Portland cement, 22 parts of high alumina cement, 36 parts of refractory soil, 80 parts of expanded vermiculite, 47 parts of perlite, 27 parts of sepiolite, 30 parts of ceramic fiber, 6 parts of polyethylene glycol-2000, 6 parts of high-efficiency water repellent, 1 part of sodium carboxymethyl cellulose, redispersible 2 parts of latex powder; the component content of thin intumescent fireproof paint (by weight): 10 parts of water, 25 parts of acrylic acid emulsion, 28 parts of ammonium polyphosphate, 15 parts of melamine, 8 parts...

Embodiment 2

[0049] A kind of thick-thin composite type fireproof coating of this embodiment, its structure schematic diagram is as follows figure 1 shown. Consists of a thick non-intumescent fire protection coating and a thin intumescent fire protection coating on a sheet metal substrate. The base material is Q235 steel plate; the component content of thick non-intumescent fireproof coating (calculated based on 42.5 type Portland cement): 100 parts of 42.5 type Portland cement, 22 parts of high alumina cement, 27 parts of refractory soil, 66 parts of expanded vermiculite, 20 parts of perlite, 27 parts of sepiolite, 30 parts of ceramic fiber, 6 parts of polyethylene glycol-2000, 6 parts of high-efficiency water repellent, 1 part of carboxymethyl cellulose, redispersible latex 2 parts of powder; the component content of thin intumescent fireproof coating (by weight): 10 parts of water, 25 parts of acrylic acid emulsion, 28 parts of ammonium polyphosphate, 15 parts of melamine, 8 parts of p...

Embodiment 3

[0065] A kind of thick-thin composite type fireproof coating of this embodiment, its structure schematic diagram is as follows figure 1 shown. Consists of a thick non-intumescent fire protection coating and a thin intumescent fire protection coating on a sheet metal substrate. The base material is Q235 steel plate; the component content of thick non-intumescent fireproof coating (calculated based on 42.5 type Portland cement): 100 parts of 42.5 type Portland cement, 22 parts of high alumina cement, 27 parts of refractory soil, 66 parts of expanded vermiculite, 20 parts of perlite, 27 parts of sepiolite, 30 parts of ceramic fiber, 6 parts of polyethylene glycol-2000, 6 parts of high-efficiency water repellent, 1 part of sodium carboxymethyl cellulose, dispersible latex 2 parts of powder; the component content of thin intumescent fireproof coating (by weight): 20 parts of water, 25 parts of acrylic acid emulsion, 21 parts of ammonium polyphosphate, 10 parts of melamine, 6 parts...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com