Anti-corrosion anti-permeability fire-retardant coating

A fire retardant coating and impermeability technology, applied in the field of fire retardant coatings, can solve the problems of poor antistatic performance, rough and uneven coal wall, slow deformation of coal wall, etc. shrinking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

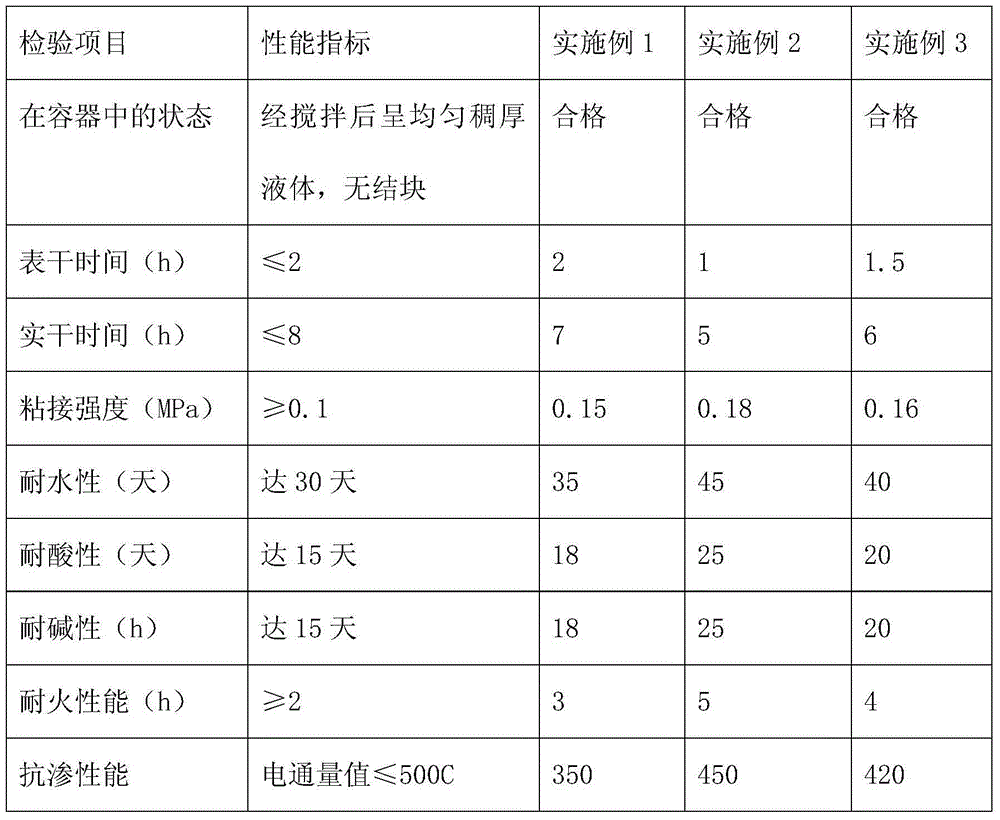

Examples

Embodiment 1

[0015] An anti-corrosion and anti-seepage fireproof coating, made of the following raw materials in parts by weight: 50 parts of Portland cement, 15 parts of flexible styrene-acrylic emulsion, 15 parts of expanded perlite, 10 parts of talcum powder, 6 parts of granite, graphite 10 parts of powder, 5 parts of magnesium hydroxide, 7 parts of aluminum hydroxide, 0.3 parts of silane powder, 3 parts of pentaerythritol, 2 parts of concrete expansion agent, 6 parts of mica powder, 3 parts of aluminum dioxide tripolyphosphate, 1 part of zinc borate . The particle size of the mica powder is 100 mesh. The preparation method of the anti-corrosion and anti-seepage type fireproof coating is to mix the polymer emulsion and water in a ratio of 1:2, and then add Portland cement, expanded perlite, talcum powder, granite, graphite powder, mica Stir and mix the powder for 15 minutes, then add magnesium hydroxide, aluminum hydroxide, silane-based powder, pentaerythritol, concrete expansion agent...

Embodiment 2

[0017] An anti-corrosion and anti-seepage fireproof coating, made of the following raw materials in parts by weight: 60 parts of Portland cement, 13 parts of flexible pure acrylic emulsion, 18 parts of expanded perlite, 15 parts of talcum powder, 5 parts of granite, graphite 12 parts of powder, 6 parts of magnesium hydroxide, 6 parts of aluminum hydroxide, 1.0 parts of silane powder, 4 parts of pentaerythritol, 2.5 parts of concrete expansion agent, 7 parts of mica powder, 2 parts of aluminum dioxide tripolyphosphate, 2 parts of zinc borate . The particle size of the mica powder is 200 mesh. The preparation method of the anti-corrosion and anti-seepage type fireproof coating is to mix the polymer emulsion and water in a ratio of 1:3, and then add Portland cement, expanded perlite, talcum powder, granite, graphite powder, mica Stir and mix the powder for 20 minutes, then add magnesium hydroxide, aluminum hydroxide, silane-based powder, pentaerythritol, concrete expansion agent...

Embodiment 3

[0019] An anti-corrosion and anti-seepage fireproof coating, made of the following raw materials in parts by weight: 80 parts of Portland cement, 10 parts of polyvinyl acetate emulsion, 20 parts of expanded perlite, 20 parts of talcum powder, 6 parts of granite, 15 parts of graphite powder, 7 parts of magnesium hydroxide, 5 parts of aluminum hydroxide, 1.5 parts of silyl powder, 5 parts of pentaerythritol, 3 parts of concrete expansion agent, 8 parts of mica powder, 3 parts of aluminum tripolyphosphate, 1 part of zinc borate share. The particle size of the mica powder is 300 mesh. The preparation method of the anti-corrosion and anti-seepage type fireproof coating is to mix the polymer emulsion and water in a ratio of 1:3, and then add Portland cement, expanded perlite, talcum powder, granite, graphite powder, mica Stir and mix the powder for 20 minutes, then add magnesium hydroxide, aluminum hydroxide, silane-based powder, pentaerythritol, concrete expansion agent, aluminum ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com