Facing expansion type silica solution water-based fireproof coating for woodware

A fire retardant coating, intumescent technology, applied in the direction of fire retardant coatings, coatings, etc., can solve problems such as poor thermal stability, and achieve the effects of good adhesion, improved blending effect, and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

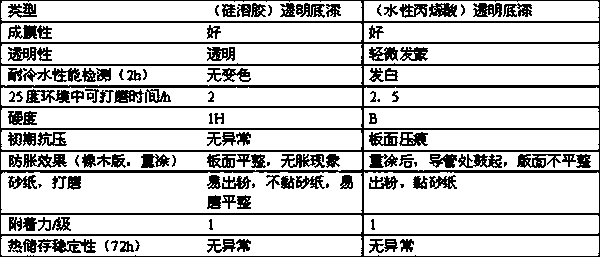

Image

Examples

Embodiment 1

[0025] A facing expansion type silica sol water-based fireproof coating for wood is characterized in that its raw materials include the following components in parts by weight: 100 parts of silica sol, 60 parts of hydroxyl polymer, 20 parts of ammonium polyphosphate, 8 parts of melamine, 5 parts of pentaerythritol, 8 parts of titanium dioxide, 10 parts of talc, 3 parts of dispersant, 0.1 part of rheological agent, 0.1 part of defoamer, 2 parts of thickener, 0.1 part of preservative, 1.0 part of film-forming aid, grinding 0.3 parts of additives, 0.1 parts of wetting agent, 0.8 parts of silane coupling agent, 0.8 parts of pH regulator, 20 parts of deionized water.

[0026] The titanium dioxide described is rutile titanium dioxide.

[0027] Described talcum powder is 1500 mesh sieve powders.

[0028] The dispersant sodium hexametaphosphate.

[0029] Described defoamer is methyl silicone oil.

[0030] The thickener is sodium carboxymethylcellulose (CMC).

[0031] The film-form...

Embodiment 2

[0038] A facing expansion type silica sol water-based fireproof coating for woodware is characterized in that its raw materials include the following components by weight: 180 parts of silica sol, 90 parts of hydroxyl polymer, 30 parts of ammonium polyphosphate, 12 parts of melamine, 8 parts of pentaerythritol, 12 parts of titanium dioxide, 20 parts of talc, 6 parts of dispersant, 0.3 parts of rheological agent, 0.3 parts of defoamer, 4 parts of thickener, 0.3 parts of preservative, 2.5 parts of film-forming aid, grinding 0.6 parts of additives, 0.3 parts of wetting agent, 1.5 parts of silane coupling agent, 1.5 parts of pH regulator, 50 parts of deionized water.

[0039] The titanium dioxide described is rutile titanium dioxide.

[0040] Described talcum powder is 1500 mesh sieve powders.

[0041] The dispersant sodium hexametaphosphate.

[0042] Described defoamer is methyl silicone oil.

[0043] The thickener is sodium carboxymethylcellulose (CMC).

[0044] The film-for...

Embodiment 3

[0051] A facing expansion type silica sol water-based fireproof coating for woodware is characterized in that its raw materials include the following components by weight: 120 parts of silica sol, 80 parts of hydroxyl polymer, 25 parts of ammonium polyphosphate, 9 parts of melamine, 6 parts of pentaerythritol, 10 parts of titanium dioxide, 16 parts of talc, 5 parts of dispersant, 0.2 parts of rheological agent, 0.2 parts of defoamer, 3 parts of thickener, 0.2 parts of preservative, 1.5 parts of film-forming aid, grinding 0.5 parts of additives, 0.2 parts of wetting agent, 1.0 parts of silane coupling agent, 1.2 parts of pH regulator, 30 parts of deionized water.

[0052] The titanium dioxide described is rutile titanium dioxide.

[0053] Described talcum powder is 1500 mesh sieve powders.

[0054] The dispersant sodium hexametaphosphate.

[0055] Described defoamer is methyl silicone oil.

[0056] The thickener is sodium carboxymethylcellulose (CMC).

[0057] The film-formin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com