Adsorbing odor-removing environment-friendly fireproof coating and preparation method thereof

A kind of fire-resistant coating, environmental protection technology, applied in the direction of fire-proof coating, anti-fouling/underwater coating, cement coating, etc., can solve the problems of inability to purify the air, poor anti-contamination performance, etc., achieve the function of improving the absorption of peculiar smell, easy to clean , Good effect of oil resistance and anti-contamination performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

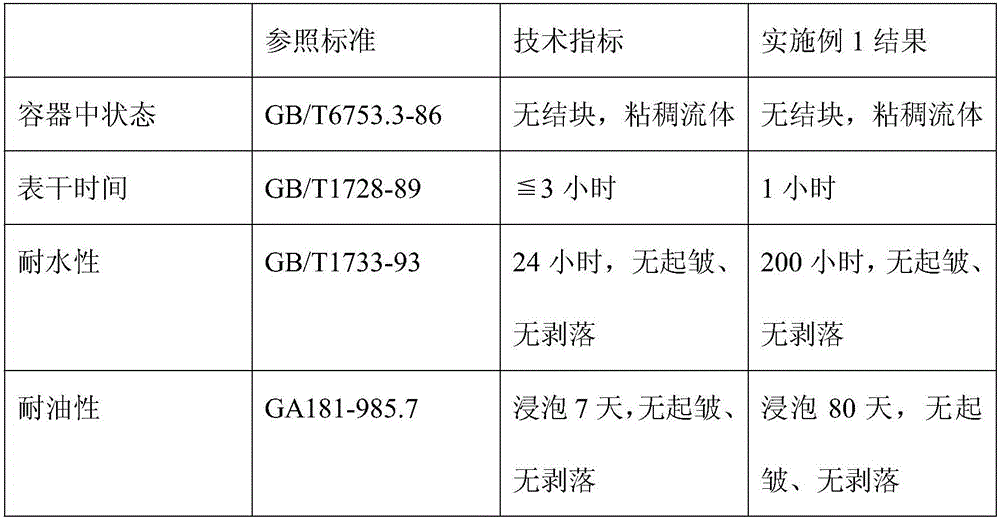

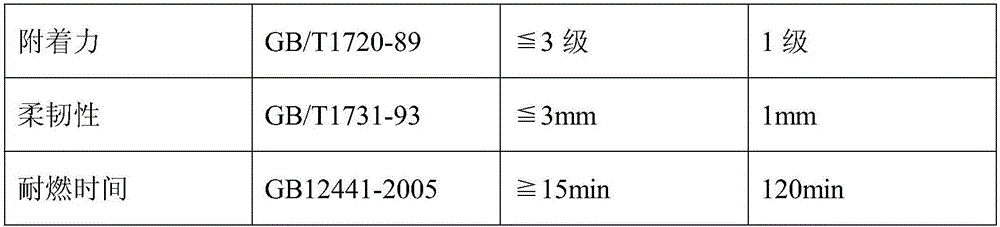

Examples

Embodiment 1

[0017] An environmentally friendly fireproof coating with adsorption and deodorization, made of the following raw materials in parts by weight: 30 parts of Portland cement, 15 parts of polyvinyl acetate emulsion, 8 parts of forsterite powder, 7 parts of high aluminum powder, modified attapulgite 5 parts of soil, 6 parts of white carbon black, 3 parts of epoxy soybean oil, 10 parts of acrylic resin, 15 parts of polytetrafluoroethylene emulsion, 5 parts of ammonium polyphosphate, 6 parts of pentaerythritol, 6 parts of porous starch, 6 parts of butyl latex , 2 parts of sodium fluorosilicate, 3 parts of sisal fiber, 5 parts of medical stone powder, 3 parts of bamboo powder, 5-7 parts of composite nanoemulsion.

[0018] The modified attapulgite is prepared by the following method: adjust the attapulgite to a slurry with a pH of 4 with oxalic acid, and add the prepared silane coupling agent KH550 / absolute ethanol solution at 75°C to react for 3-4 After one hour, take it out and wash...

Embodiment 2

[0025] An environmentally friendly fireproof coating with adsorption and deodorization, made of the following raw materials in parts by weight: 50 parts of Portland cement, 2 parts of polyvinyl acetate emulsion, 10 parts of forsterite powder, 6 parts of high alumina powder, modified attapulgite 6 parts of soil, 5 parts of white carbon black, 3 parts of epoxy soybean oil, 12 parts of acrylic resin, 20 parts of polytetrafluoroethylene emulsion, 5 parts of ammonium polyphosphate, 5 parts of pentaerythritol, 6 parts of porous starch, 7 parts of butyl latex , 2 parts of sodium fluorosilicate, 5 parts of sisal fiber, 6 parts of medical stone powder, 4 parts of bamboo powder, and 6 parts of composite nanoemulsion.

[0026] The modified attapulgite is prepared by the following method: adjust the attapulgite to a slurry with a pH of 4 with oxalic acid, and add the prepared silane coupling agent KH550 / absolute ethanol solution at 75°C to react for 3-4 After one hour, take it out and was...

Embodiment 3

[0033] An environmentally friendly fireproof coating with adsorption and clean odor, made of the following raw materials in parts by weight: 50 parts of Portland cement, 10 parts of polyvinyl acetate emulsion, 10 parts of forsterite powder, 5 parts of high alumina powder, modified attapulgite 7 parts of soil, 6 parts of white carbon black, 4 parts of epoxy soybean oil, 15 parts of acrylic resin, 30 parts of polytetrafluoroethylene emulsion, 6 parts of ammonium polyphosphate, 6 parts of pentaerythritol, 7 parts of porous starch, 8 parts of butyl latex , 3 parts of sodium fluorosilicate, 5 parts of sisal fiber, 8 parts of medical stone powder, 3 parts of bamboo powder, and 7 parts of composite nanoemulsion.

[0034] The modified attapulgite is prepared by the following method: adjust the attapulgite to a slurry with a pH of 4 with oxalic acid, and add the prepared silane coupling agent KH550 / absolute ethanol solution at 75°C to react for 3-4 After one hour, take it out and wash ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com