Flame-retardant rigid polyurethane foam of hydrophobic graphene aerogel coating and preparation method of flame-retardant rigid polyurethane foam

A graphene aerogel, rigid polyurethane technology, applied in coatings, fire-resistant coatings, etc., can solve problems such as being unsuitable for large-scale promotion, strict preparation environment requirements, complex preparation processes, etc. The effect of simple process and low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

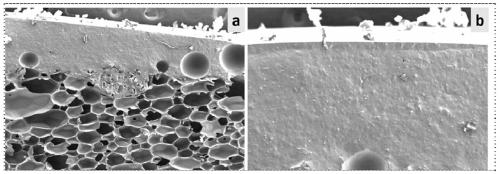

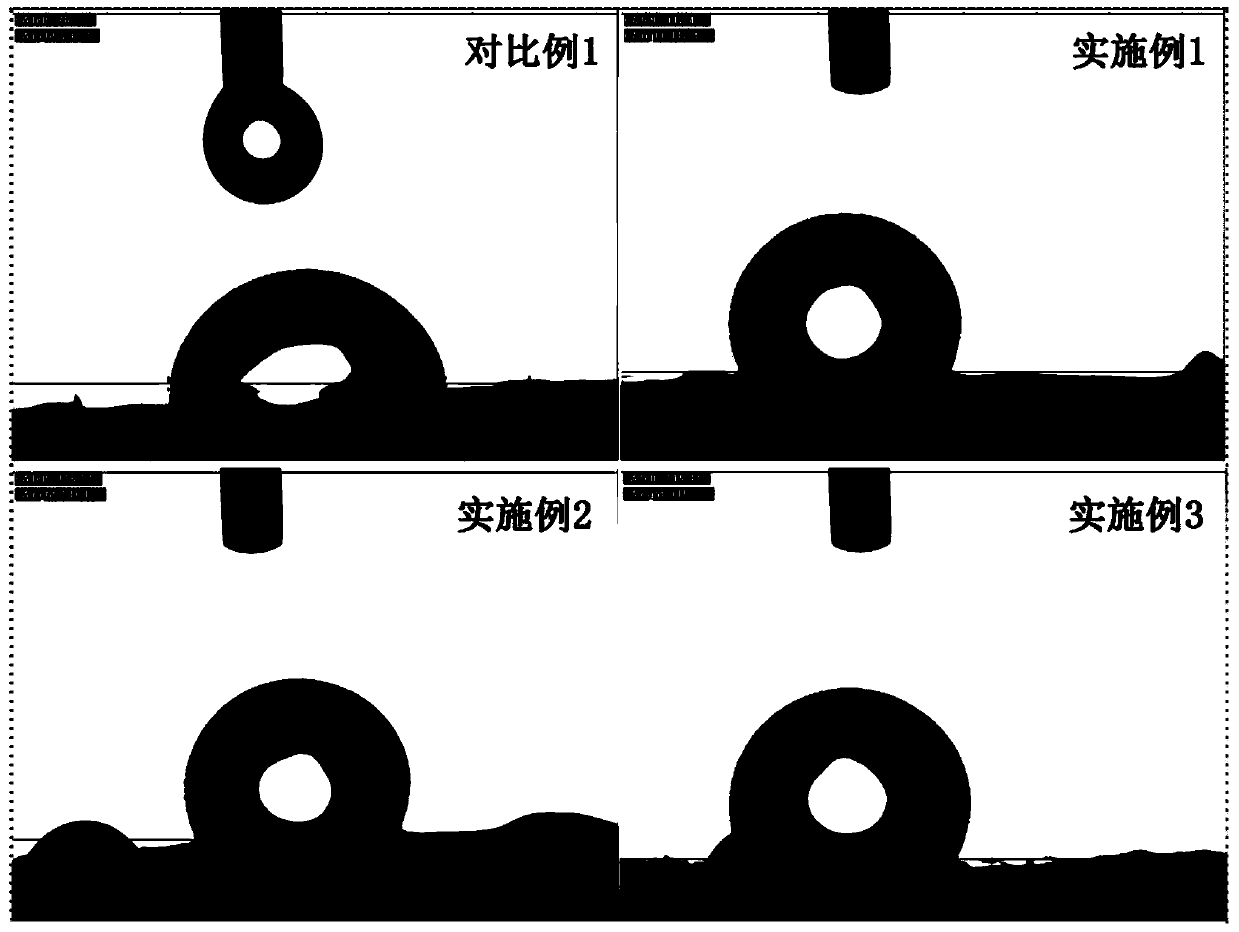

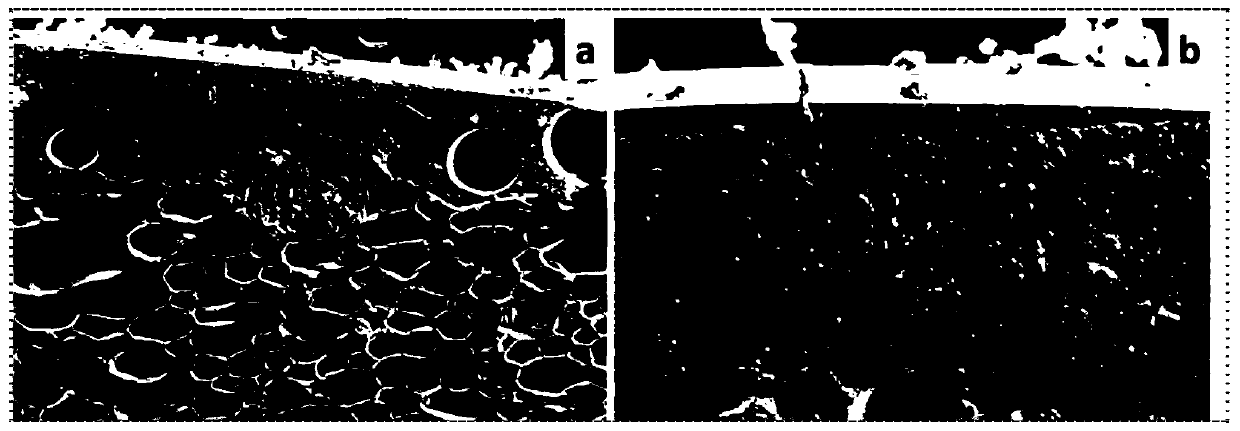

[0045] Embodiment 1 prepares a kind of method of hydrophobic graphene aerogel coating flame retardant rigid polyurethane foam, comprises the steps:

[0046](1) Weigh 26g ethyl orthosilicate, 28.57g ethanol and 2.25g distilled water and mix evenly (the molar ratio of orthosilicate to ethanol is 1:5, and the molar ratio of ethanol to water is 5:1) to obtain a solution , use 0.1mol / L hydrochloric acid solution to adjust the pH value of the solution to 4.0, stir, the stirring rate is 200rpm, the stirring time is 20min, then seal and stand for 18h to carry out the hydrolysis reaction to obtain the hydrolyzate;

[0047] (2) 25g concentration of reduced graphene oxide solution that is 1mg / mL is added to the 60g hydrolyzate described in step (1) (the mass ratio of reduced graphene oxide solution to hydrolyzate is 1:2.4), ultrasonic dispersion treatment, ultrasonic The ultrasonic frequency of the treatment is 30kHz, and the ultrasonic treatment time is 30min to obtain a mixed solution,...

Embodiment 2

[0056] Embodiment 2 prepares the method for a kind of hydrophobic graphene airgel coating flame-retardant rigid polyurethane foam, comprises the steps:

[0057] (1) Weigh 26g of tetraethyl orthosilicate, 34.29g of ethanol and 2.25g of distilled water and mix evenly (the molar ratio of tetraethyl orthosilicate to ethanol is 1:6, and the molar ratio of ethanol to water is 6:1) to obtain a solution , use 0.1mol / L hydrochloric acid solution to adjust the pH value of the solution to 3.5, stir, the stirring rate is 150rpm, the stirring time is 30min, then seal and stand for 24h to carry out the hydrolysis reaction to obtain the hydrolyzate;

[0058] (2) 17g concentration of reduced graphene oxide solution that is 3mg / mL is added to the 66.3 hydrolyzate described in step (1) (the mass ratio of reduced graphene oxide solution to hydrolyzate is 1:3.9), ultrasonic dispersion treatment, ultrasonic The ultrasonic frequency of treatment is 25kHz, and the time of ultrasonic treatment is 45m...

Embodiment 3

[0067] Embodiment 3 prepares the method for a kind of hydrophobic graphene airgel coating flame-retardant rigid polyurethane foam, comprises the steps:

[0068] (1) Weigh 26g of tetraethyl orthosilicate, 40g of ethanol and 2.25g of distilled water and mix evenly (the molar ratio of tetraethyl orthosilicate to ethanol is 1:7, and the molar ratio of ethanol to water is 7:1) to obtain a solution, Use 0.1mol / L hydrochloric acid solution to adjust the pH value of the solution to 3.0, stir it, the stirring rate is 100rpm, and the stirring time is 40min, then seal it and let it stand for 30h to carry out the hydrolysis reaction to obtain the hydrolyzed solution;

[0069] (2) The reduced graphene oxide solution that is 5mg / mL is added to the 85g hydrolyzate described in step (1) by 10g concentration (the mass ratio of reduced graphene oxide solution and hydrolyzate is 1:8.5), ultrasonic dispersion treatment, ultrasonic The ultrasonic frequency of the treatment is 20kHz, and the ultras...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com