Fireproof glue liquid matrix and preparation method thereof, and fireproof glue liquid and preparation method thereof

A glue and matrix technology, used in chemical instruments and methods, adhesives, graft polymer adhesives, etc., can solve the problems of high viscosity of fireproof glue, inability to prepare ultra-thin composite fireproof glass with fireproof layer, etc. Good denaturation, high thixotropy, and the effect of increasing thixotropy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067] This embodiment provides a method for preparing a fireproof glue matrix, comprising the following steps:

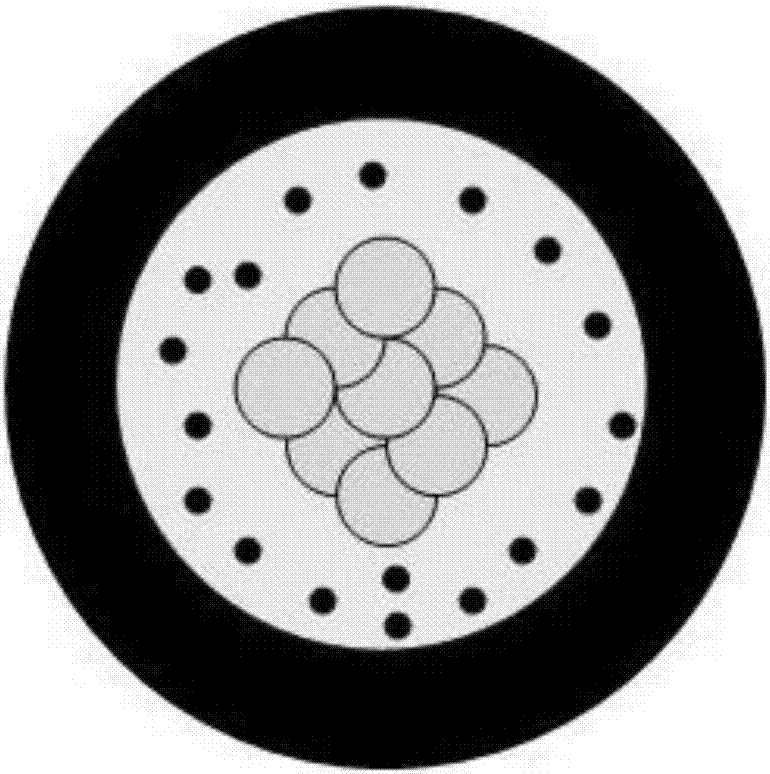

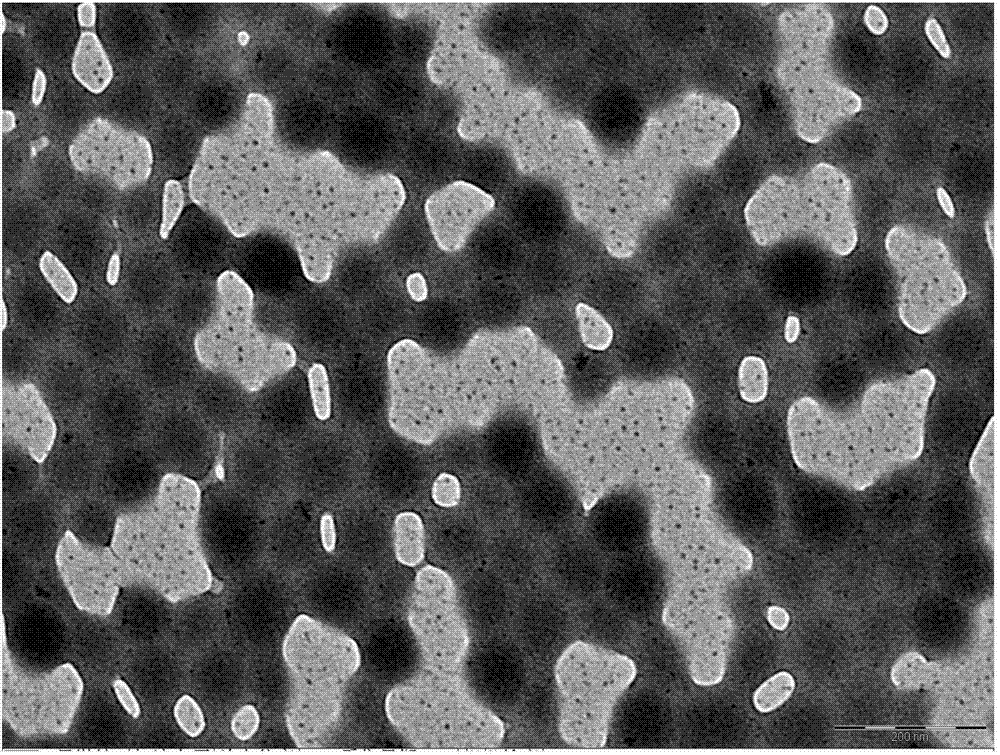

[0068] (1) Mix glycerin, polymerized monomers, and deionized water at a mass ratio of 15:2:50, stir evenly, and prepare a mixed solution of inner shell materials. In this step, the polymerized monomers include a mass ratio of 2:0.01 : 0.01 of acrylic acid, methacrylic acid and polyacrylamide;

[0069] (2) Mix nano-silica particles with a particle size of 60nm and the inner shell material mixture, after ultrasonic dispersion, let stand for 24 hours, heat up to 60°C, and add a redox trigger agent, polymerized for 30min, and polymerized monomers were polymerized under the action of a redox initiator, and formed an inner shell by polymerizing outside the nano-silica particles to obtain a soap-free seed emulsion. In this step, the inner shell material mixed solution, The mass ratio of nano silicon dioxide particles to redox initiator is 30:60:0.01;

[0070] (3) Mix th...

Embodiment 2

[0073] This embodiment provides a method for preparing a fireproof glue matrix, comprising the following steps:

[0074] (1) Mix glycerin, polymerized monomer and deionized water in a mass ratio of 20:25:35, stir evenly, and prepare a mixed solution of inner shell material. In this step, the polymerized monomer includes a mass ratio of 10:10 :5 acrylic acid, methacrylic acid and polyacrylamide;

[0075] (2) Mix nano-silica particles with a particle size of 100nm and the inner shell material mixture, after ultrasonic dispersion, let stand for 24 hours, raise the temperature to 65°C, and add a redox trigger agent, polymerized for 30min, and polymerized monomers were polymerized under the action of a redox initiator, and formed an inner shell by polymerizing outside the nano-silica particles to obtain a soap-free seed emulsion. In this step, the inner shell material mixed solution, The mass ratio of nano silicon dioxide particles to redox initiator is 50:20:0.04;

[0076] (3) M...

Embodiment 3

[0079] This embodiment provides a method for preparing a fireproof glue matrix, comprising the following steps:

[0080] (1) The mass ratio of glycerin, polymerized monomer, sucrose, polyol, heat stabilizer, sodium fluorosilicate, potassium hydroxide and deionized water is 15:25:2:2:0.3:0.05:0.1: 40 to mix and stir evenly to prepare the inner shell material mixture. In this step, the polymerized monomers include acrylic acid, methacrylic acid and polyacrylamide with a mass ratio of 10:0.01:5, and polyols include acrylic acid with a mass ratio of 1:1. xylitol and pentaerythritol, heat stabilizer includes borax and boric acid with a mass ratio of 1:1;

[0081] (2) Mix silica particles with a particle size of 60nm and the inner shell material mixture, after ultrasonic dispersion, let it stand for 24 hours, heat up to 65°C, and add a redox initiator after filling nitrogen protection at a speed of 250rmp , polymerized for 30 minutes, so that the polymerized monomers undergo a poly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com