Cut, slash and/or abrasion resistant protective fabric and lightweight shaped knit garment made therefrom having improved appearance and cut resistance

a protective fabric and lightweight technology, applied in the direction of protective garments, knitwear, overgarments, etc., can solve the problems of garments that cannot provide a satisfactory level of protection to the wearer of the garment, other known such garments suffer from numerous disadvantages, and can easily be damaged, so as to achieve a satisfactory level of cut

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

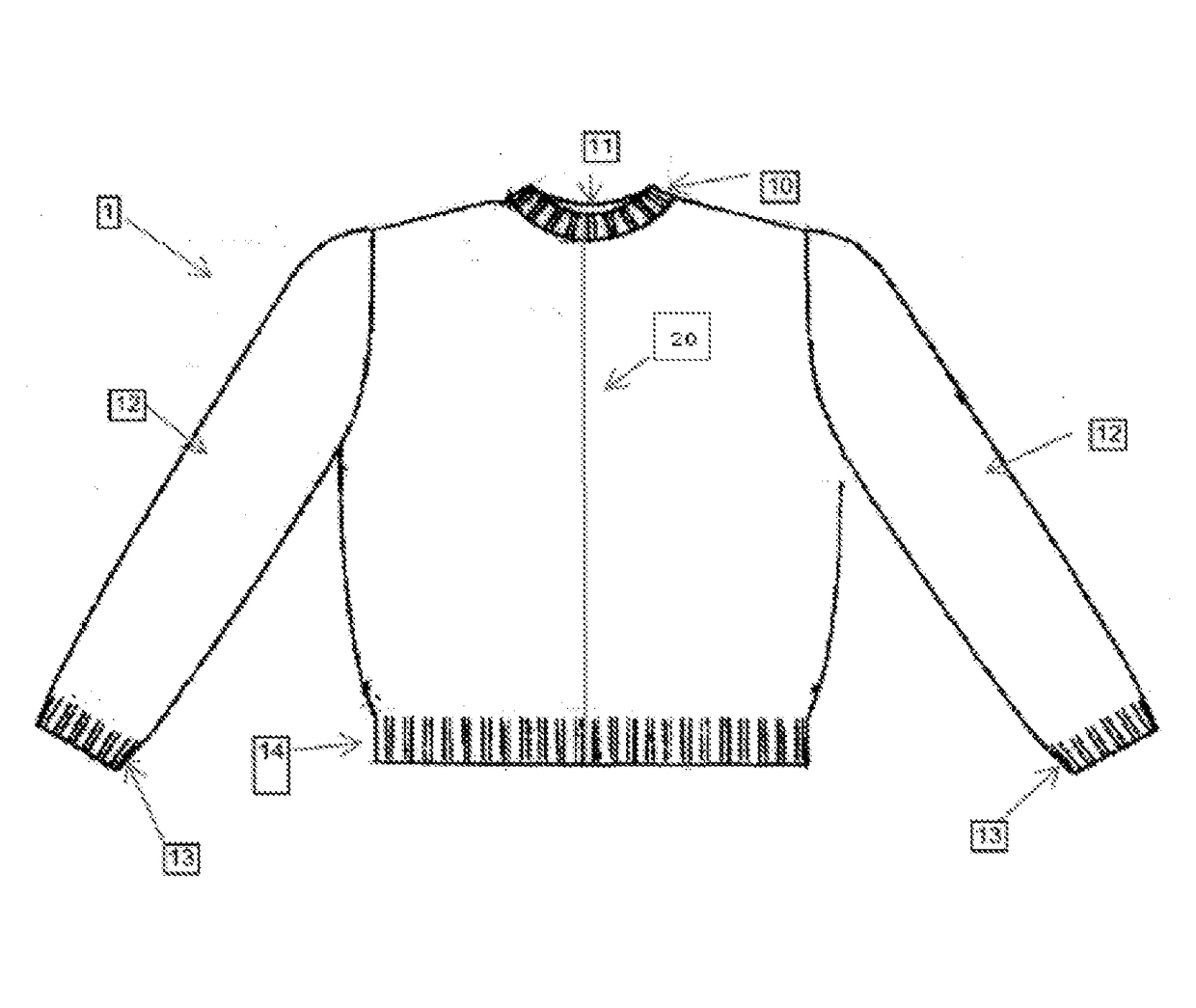

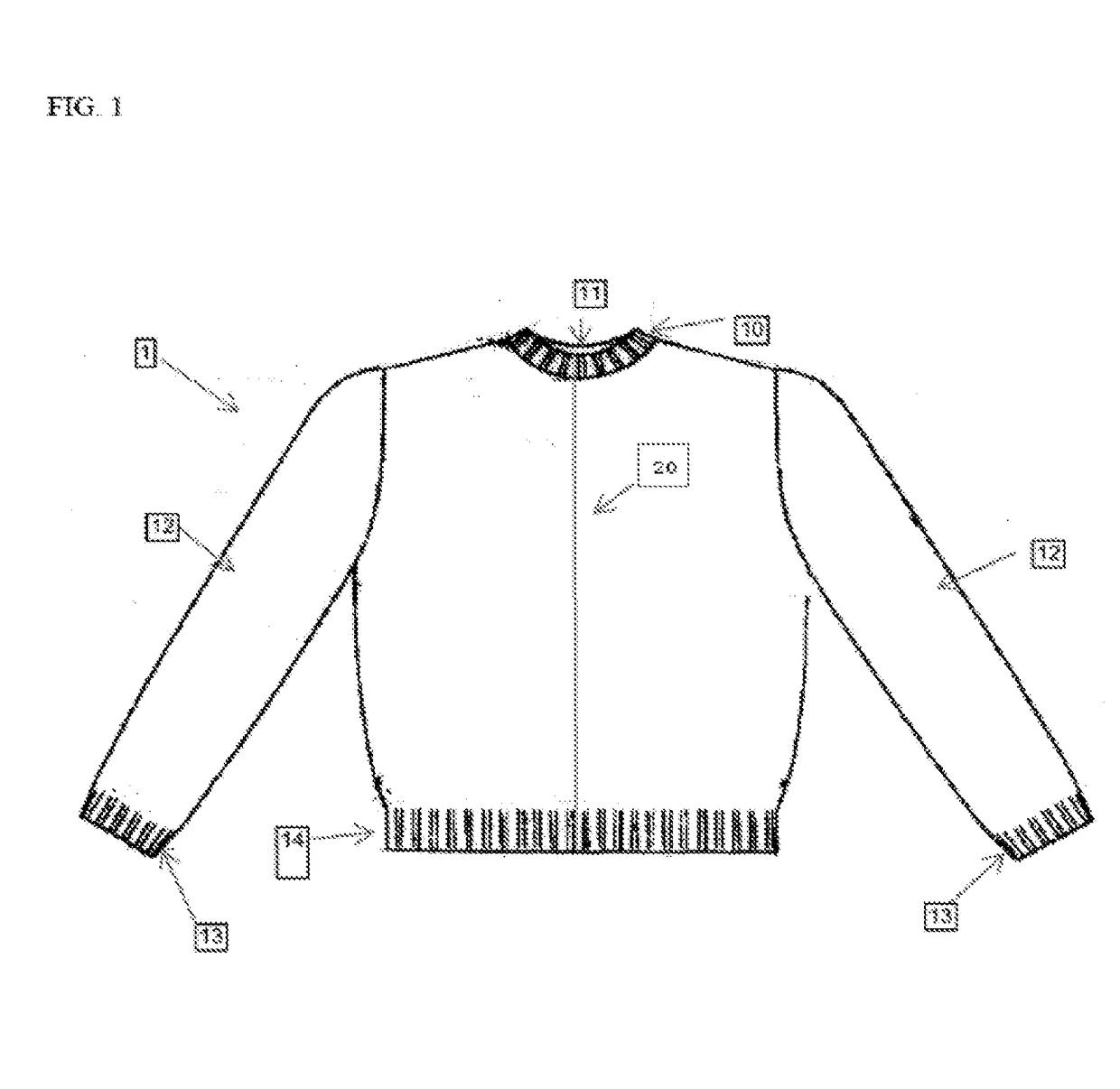

[0056]As an example of a garment prepared according to the present invention, FIG. 1 shows an example of a knit sweater or jacket construction. The sweater can have any desired measurements, depending on the size of the intended wearer. Such sizes and the needed measurements are well known in the art. For example, a knit sweater (1) as shown in FIG. 1 would typically have a rib (10) around the neck opening (11) approximately 1 inch wide, with a front neck drop of 4-4.75 inches and a back neck drop of about 1 inch. The sleeves (12) would typically have a rib (13) at the end approximately 2.5 inches wide. The bottom of the sweater torso would likewise have a rib (14) of approximately 2.5 inches width. The line indicates as (20) represents a zipper, which may optionally be present, depending on whether the garment is a sweater (no zipper) or a jacket (with zipper).

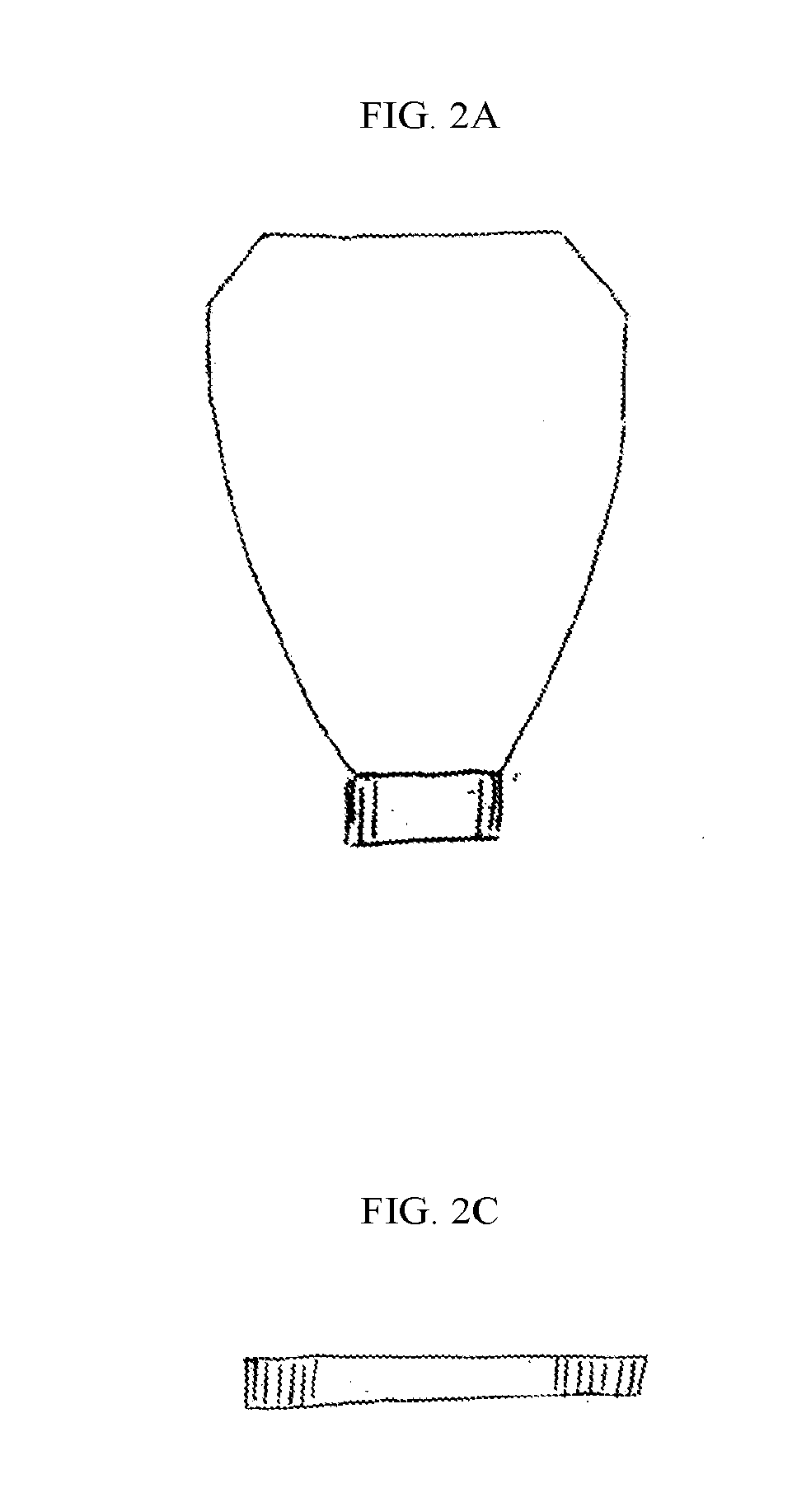

[0057]FIGS. 2A-2C show the shaped knit fabric panels that would be used to prepare a preferred embodiment of sweater simila...

embodiment 1

[0059]A shaped knit garment, comprising:

[0060]one or more fabric panels prepared from at least one cut, slash and / or abrasion resistant composite yarn, wherein the composite yarn comprises a core yarn and one or more wrapped yarn layers, wherein when more than one wrap layer is present, each wrap layer is wrapped in a direction opposite any adjacent wrap layer, wherein the shaped knit garment has a cut resistance of at least 5 (as measured by ASTM-F1790-97).

embodiment 2

[0061]The shaped knit garment of embodiment 1, wherein the fabric weight is no more than 27.9 OPSY.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| cut resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com