Water permeable artificial turf and method of making same

a technology of artificial turf and permeable water, applied in the field of artificial turf, can solve the problems of water drainage, expensive and complex equipment, etc., and achieve the effect of cost saving in manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0072]A synthetic turf product is prepared in accordance with the present invention. The turf comprises a 2.5 inch pile height polyethylene face fiber tufted into a woven polypropylene primary backing. An aqueous dispersion of thermoplastic polymer particles is prepared having the following formulation as shown in Table 2:

TABLE 2IngredientPercent by WeightWater69.3Dispersion agent (xanthan gum)0.2Polyethylene particles (having an average30.0particle size of 80 microns)Sodium lauryl sulfate0.5

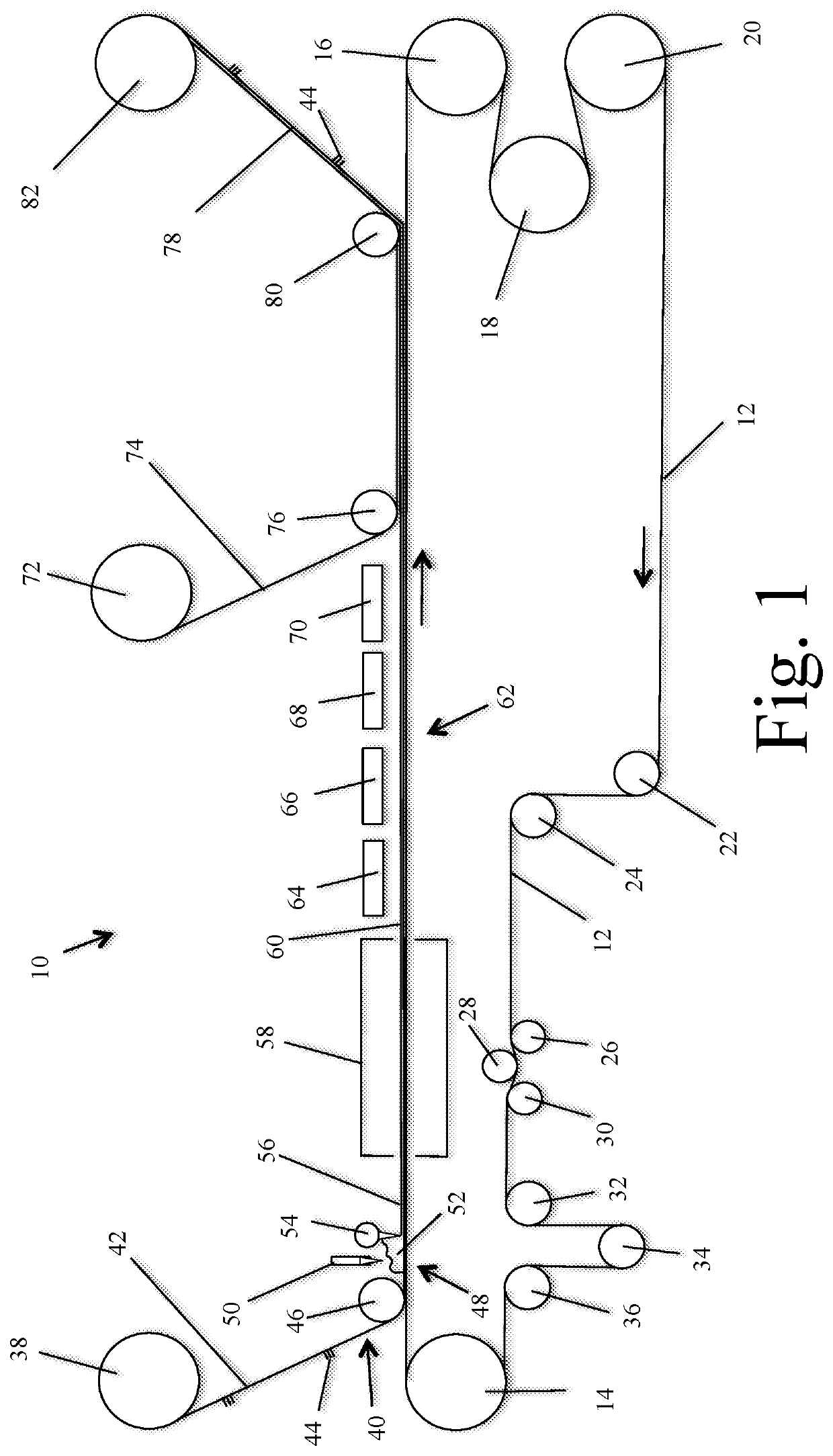

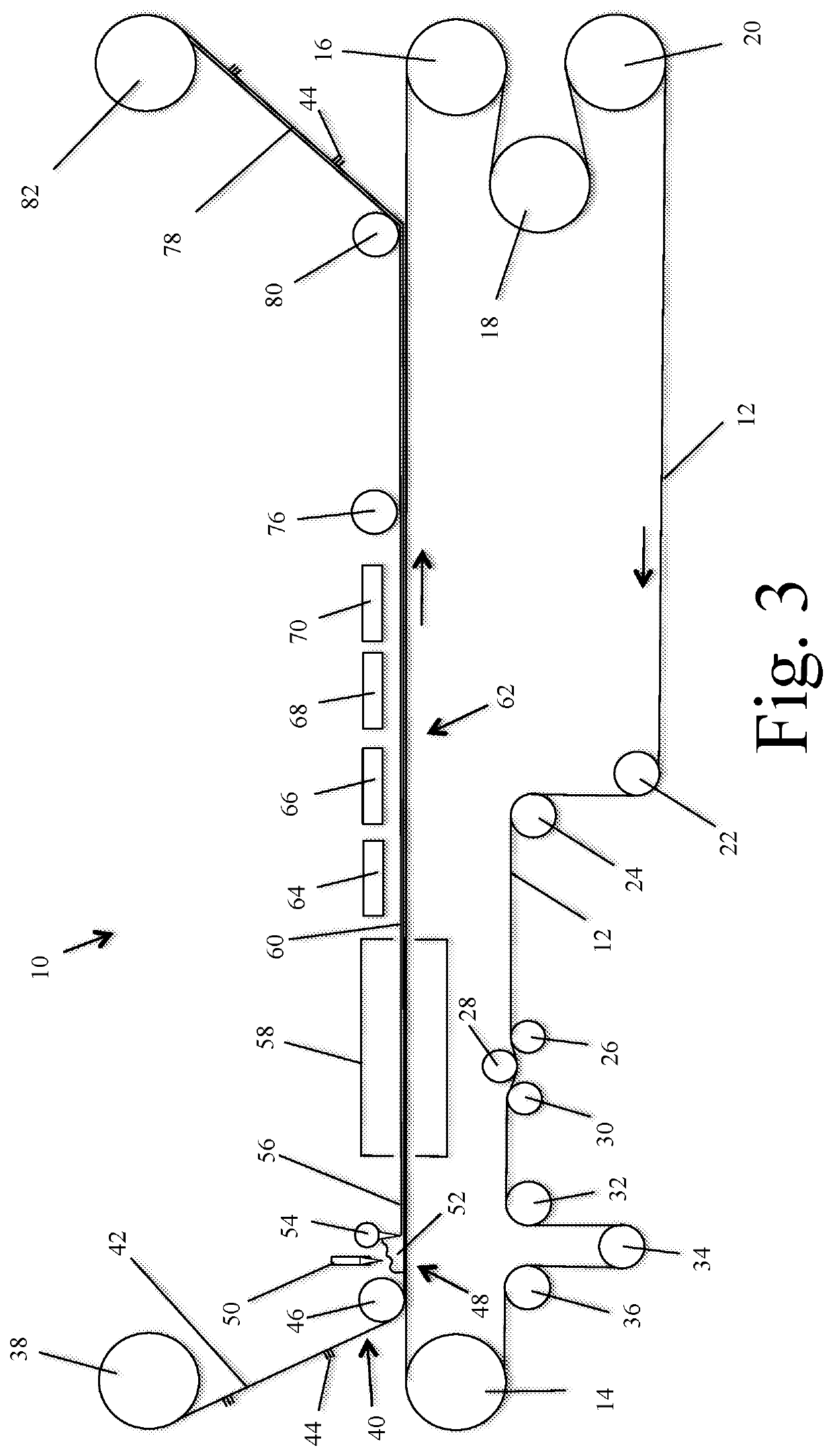

[0073]The synthetic turf is processed in accordance with the present invention as described above and shown in FIG. 1. The aqueous dispersion of Table 2 is converted to a foam in a frothing machine. The foamed aqueous dispersion of thermoplastic polymer particles is applied to the primary backing and formed into a uniform layer at the rate of 16 ounces of polymer per square yard and the resulting layer is approximately 0.25 inches thick. The foam coated polypropylene primary backing is heated in...

example 2

[0074]A synthetic turf product is prepared in accordance with the present invention. The synthetic turf comprises a 2.5 inch pile height polyethylene face fiber tufted into a woven polypropylene primary backing. An aqueous dispersion of thermoplastic polymer particles is prepared having the formulation as shown in Table 2 above.

[0075]The synthetic turf is processed in accordance with the present invention as described above. The aqueous dispersion of Table 2 is converted to a foam in a frothing machine. The foamed aqueous dispersion of thermoplastic polymer particles is applied to the synthetic turf polypropylene primary backing and formed into a uniform layer at the rate of 16 ounces per square yard and the resulting layer is approximately 0.25 inches thick. The foam coated polypropylene primary backing is heated in a heated oven at a temperature of 212° F. for a period of 4 minutes until the aqueous dispersion is substantially dry. In the heated oven the foam quickly collapses and...

example 3

[0076]A 2.5 inch pile height polyethylene face fiber synthetic turf with a polypropylene woven primary and a thermoset polyurethane precoat is selected for testing. The synthetic turf is comprised of 51% by weight polyethylene, 14% by weight polypropylene and 35% by weight thermoset polyurethane. The synthetic turf is removed from a sports facility using a Turf Muncher to strip the turf from the field, 95% by weight of the infill material is remove and the turf is rolled into a roll. The turf roll is cut into strips 36 inches wide. The strips are fed into a Series 14 Grinder from Jordon Reduction Solutions of Birmingham, Ala. where the turf strips are ground / cut into particles having a maximum dimension of ⅜ inch. The size reduced synthetic turf is processed through a 4 inch single screw extruder with a 26:1 L / D at 400° F., which is a sufficient temperature to melt the thermoplastic material from which the synthetic turf is made. The extruder is equipped with a 300 horsepower electr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com