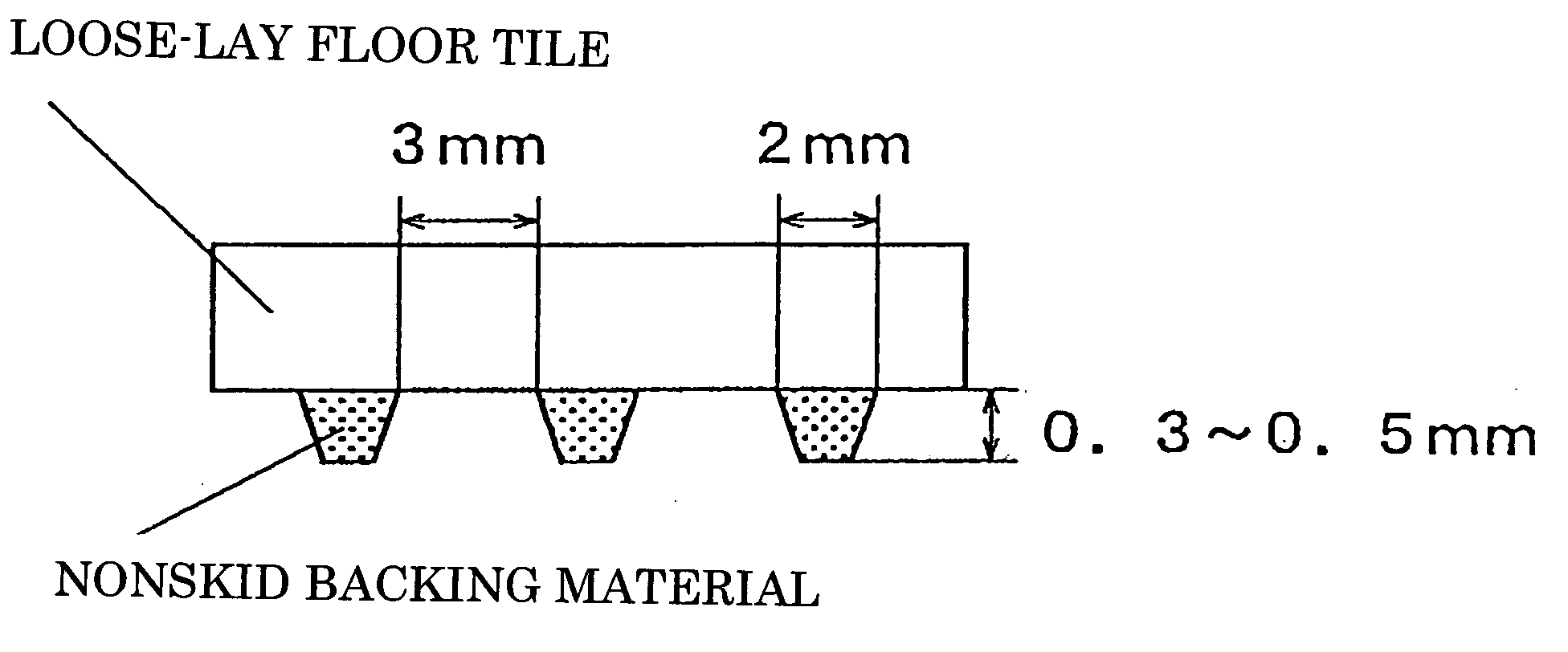

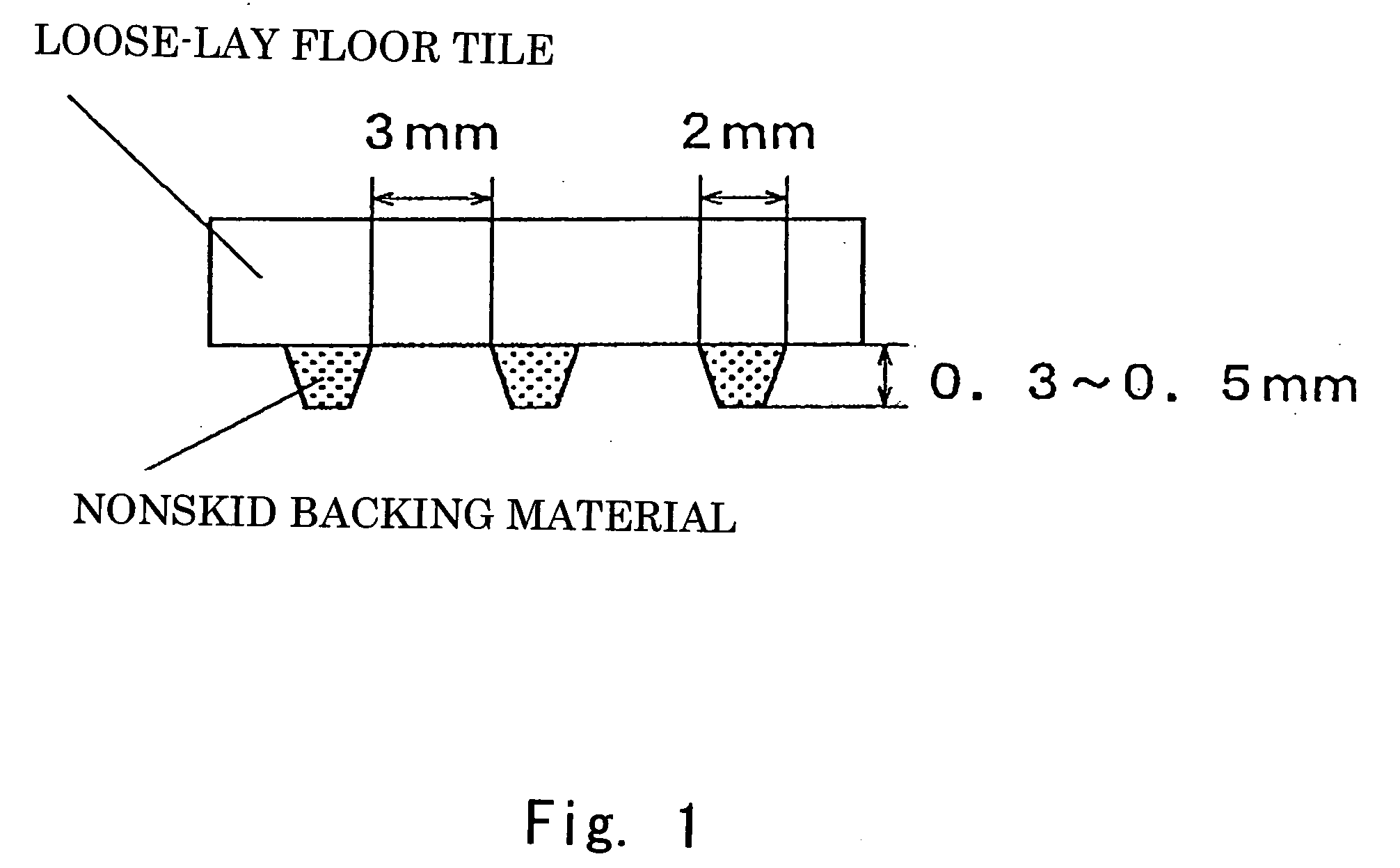

Free laying floor tile having pvc based backing material for preventing tile from slipping provided on back surface thereof

a backing material and free-laying technology, applied in the field of loose-leaf floor tiles, can solve the problems of poor water resistance, prone to fracture of foamed material sheets, and difficulty in separating sheets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0050] A nonskid backing material in accordance with the present invention was prepared by mixing the following components, followed by mechanically foaming the resultant mixture (the expansion rate: 2.8). As for the amount of the component, “part” means “part by weight”.

A paste of a PVC resin80parts(a copolymer containing 7% of vinyl acetate;the number-average molecular weight: 1,700)A PVC resin for blending20parts(a copolymer containing 5% of vinyl acetate;the number-average molecular weight: 1,100)A plasticizer (DOP)120partsCalcium carbonate treated with fatty10partsacids on the surfaceA silicone-based foam stabilizer7partsA modified urea-based thixotropy agent0.2parts

[0051] On the back face of one loose-lay floor tile which had a size of a 50 cm square and a thickness of 5 mm and made of a plastic, stripes were formed with 50 g of the nonskid backing material prepared above. The floor tile having the backing material was heated by an infra-heater at 165° C. for 5 seconds to so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com