Device and method for testing impact resistance of plastic pipe

A technology for capacity testing and plastic pipes, which is applied in the direction of measuring devices, using repeated force/pulsation force to test the strength of materials, and analyzing materials, etc., can solve the problems of incomplete test results, troublesome operation, high equipment cost, etc., and achieve convenient test methods Implementation, comprehensive testing results, comprehensive testing results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

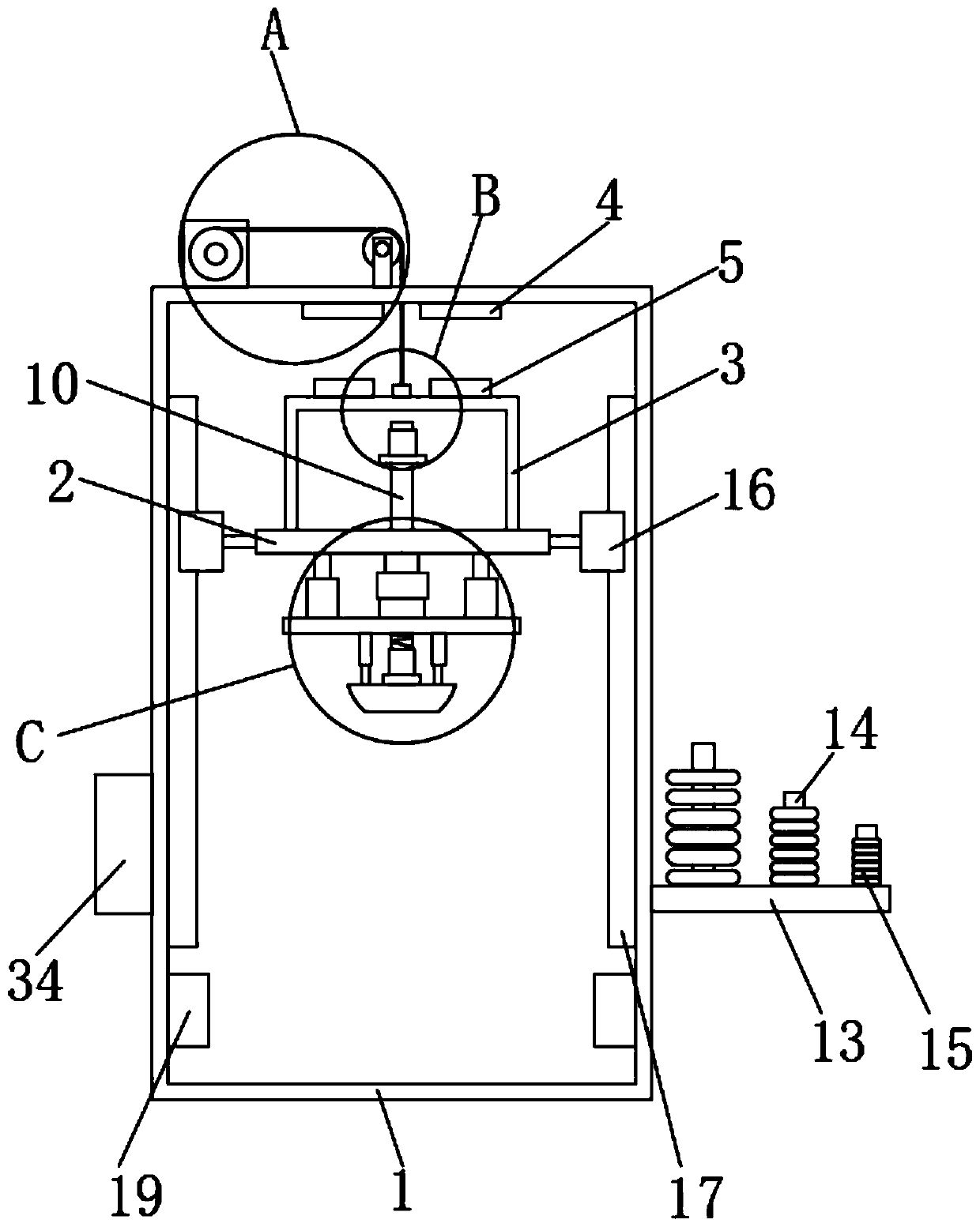

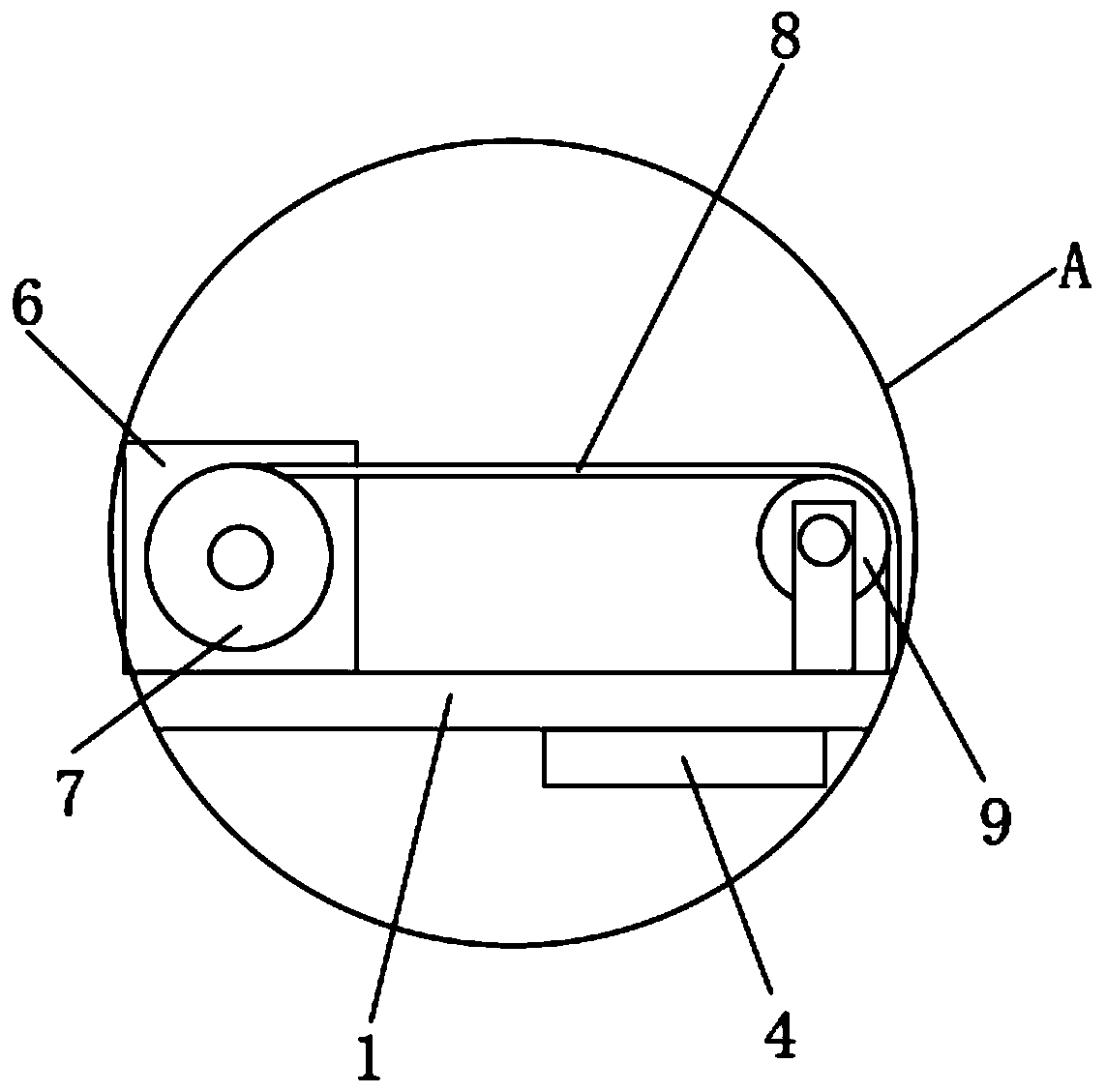

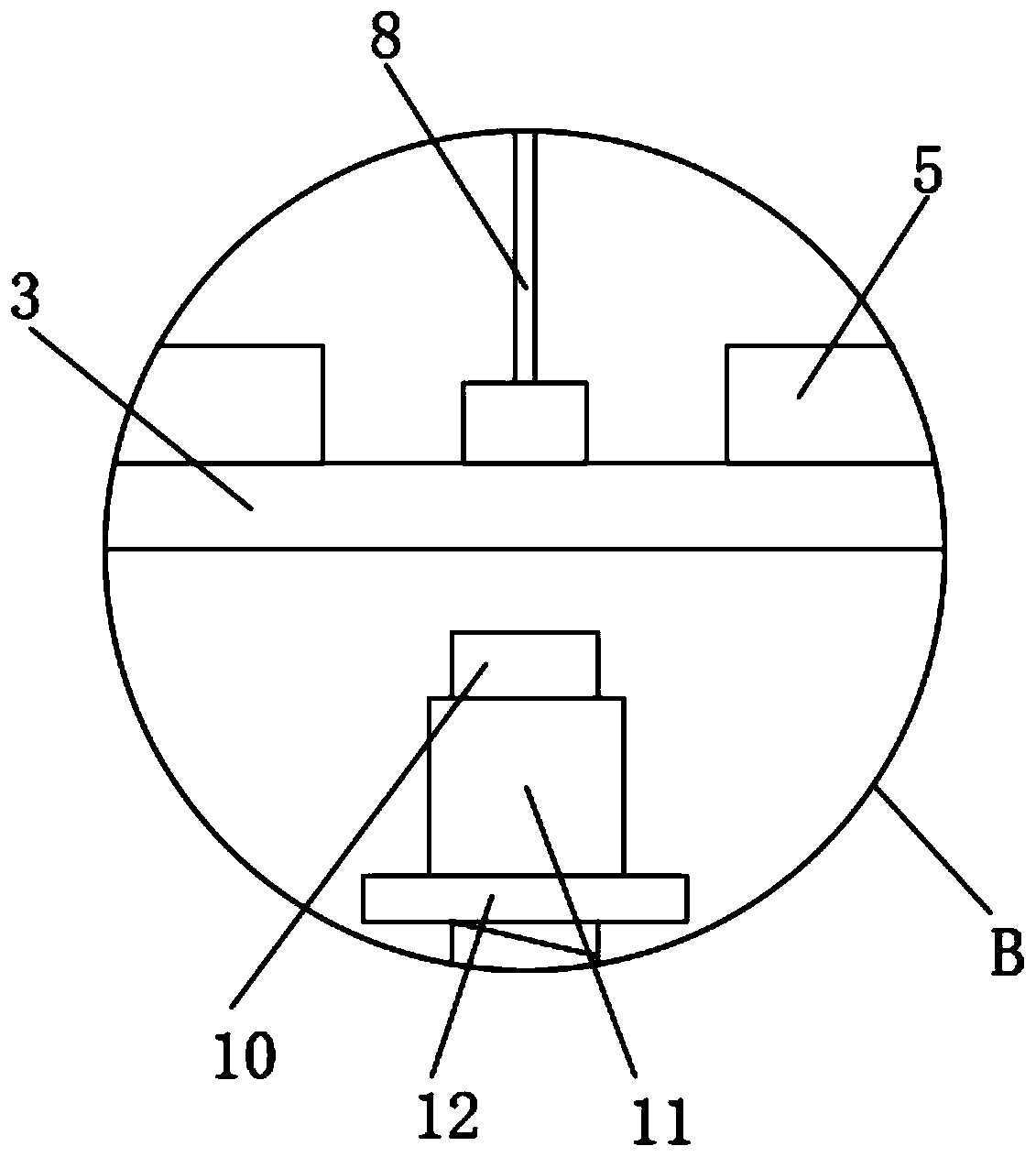

[0048] see Figure 1-3 and Figure 5 A device for testing the impact resistance of plastic pipes, comprising a device frame 1, a support plate 2 is movably installed in the device frame 1, the top of the support plate 2 is fixedly connected with a C-shaped suspender 3, and the device frame 1 Two electromagnets 4 are fixedly installed on the top inner wall, and two iron blocks 5 are fixedly connected to the top of the boom 3, and the two iron blocks 5 correspond to the two electromagnets 4 one by one, and the iron blocks 5 are located on the corresponding electromagnet 4 Directly below, when the electromagnet 4 is energized, it can absorb the iron block 5, and then fix the suspender 3 in the air, and after the electromagnet 4 is powered off, the magnetism disappears, causing the suspender 3 to fall downward, and then drives the impact block 22 Falling, the pipe to be tested can be impacted, so as to test the impact resistance of the pipe. The top of the device frame 1 is fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com