Impact resistance detection equipment for automobile shock absorber support production

A technology for automobile shock absorbers and testing equipment, which is applied in vehicle suspension/shock absorbing mechanism testing, impact testing, machine/structural component testing, etc., and can solve the problem of single detection methods, inability to detect shock absorber bracket shocks, and detection efficiency Low-level problems, to achieve the effect of increasing stability, good anti-skid effect, and ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

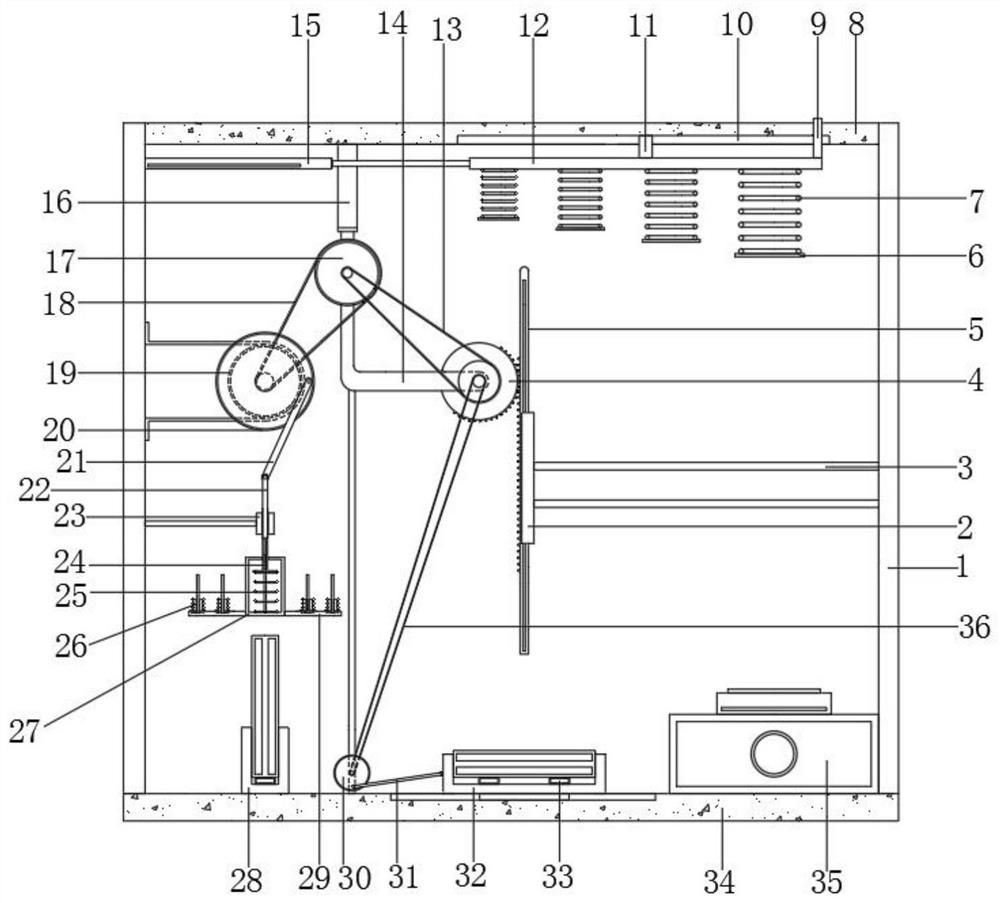

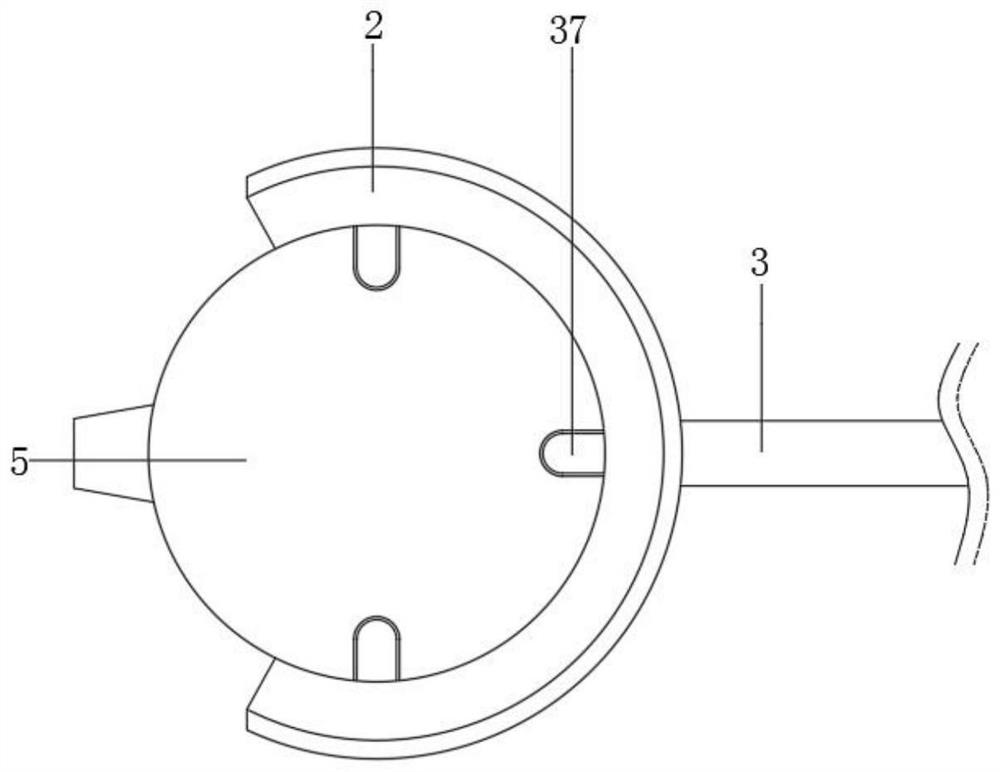

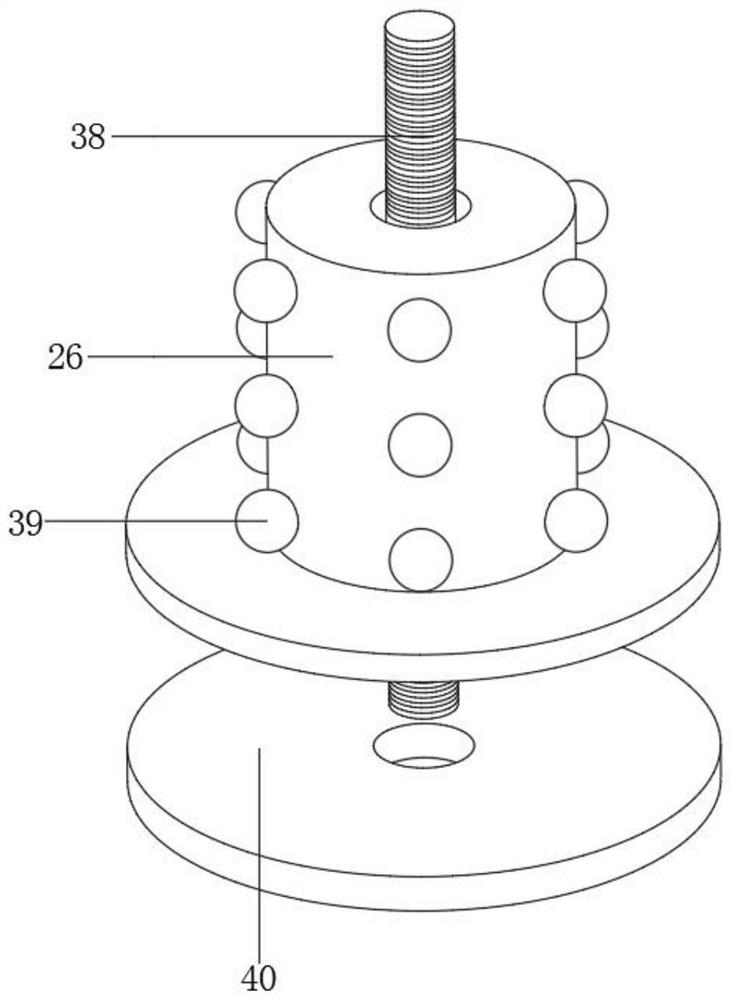

[0029] refer to Figure 1-4 , a kind of shock resistance testing equipment for the production of automobile shock absorber brackets, including a base plate 34, side support plates 1 are vertically welded on both sides of the top outer wall of the base plate 34, and the top of the side support plate 1 is welded with the same top plate 8. The two sides of the top outer wall of the base plate 34 are respectively fixedly installed with tooling 1 28 and slidingly connected with tooling 2 32, and the tops of tooling 1 28 and tooling 2 32 are respectively provided with adjustable impact mechanisms, and the adjustable impact mechanism is equipped with a transmission mechanism , and the adjustable impact mechanism includes a rotating motor 19 fixed to one side of the side support plate 1 by bolts, the transmission mechanism includes a runner 20 keyed to the output shaft of the rotating motor 19, and the bottom outer wall of the top plate 6 is welded with a U Shaped frame 16, the bottom...

Embodiment 2

[0040] refer to Figure 5 , a kind of anti-shock detection equipment for the production of automobile shock absorber brackets. Compared with Embodiment 1, this embodiment also includes a magnetic block 41 fixedly installed on the opposite side of the top plate 6 and the mounting plate 12, and corresponds to two magnetic blocks. The blocks 41 repel each other; the magnetic blocks 41 repelling each other can generate a corresponding repulsive force during the upward movement of the top plate 6 .

[0041] When the present invention is used: mutually repulsive magnetic blocks 41 are set, and corresponding repulsive force can be generated during the upward movement of the top plate 6, thereby further increasing the kinetic energy of the punch rod 5 to achieve the purpose of ensuring the detection effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com