Numerical control electric cloth cutter

A cutting machine and electric technology, which is applied in the direction of shearing equipment, shearing devices, and accessories of shearing machines, can solve problems such as unstable operation and single function in operation, and achieve the effect of large torque and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

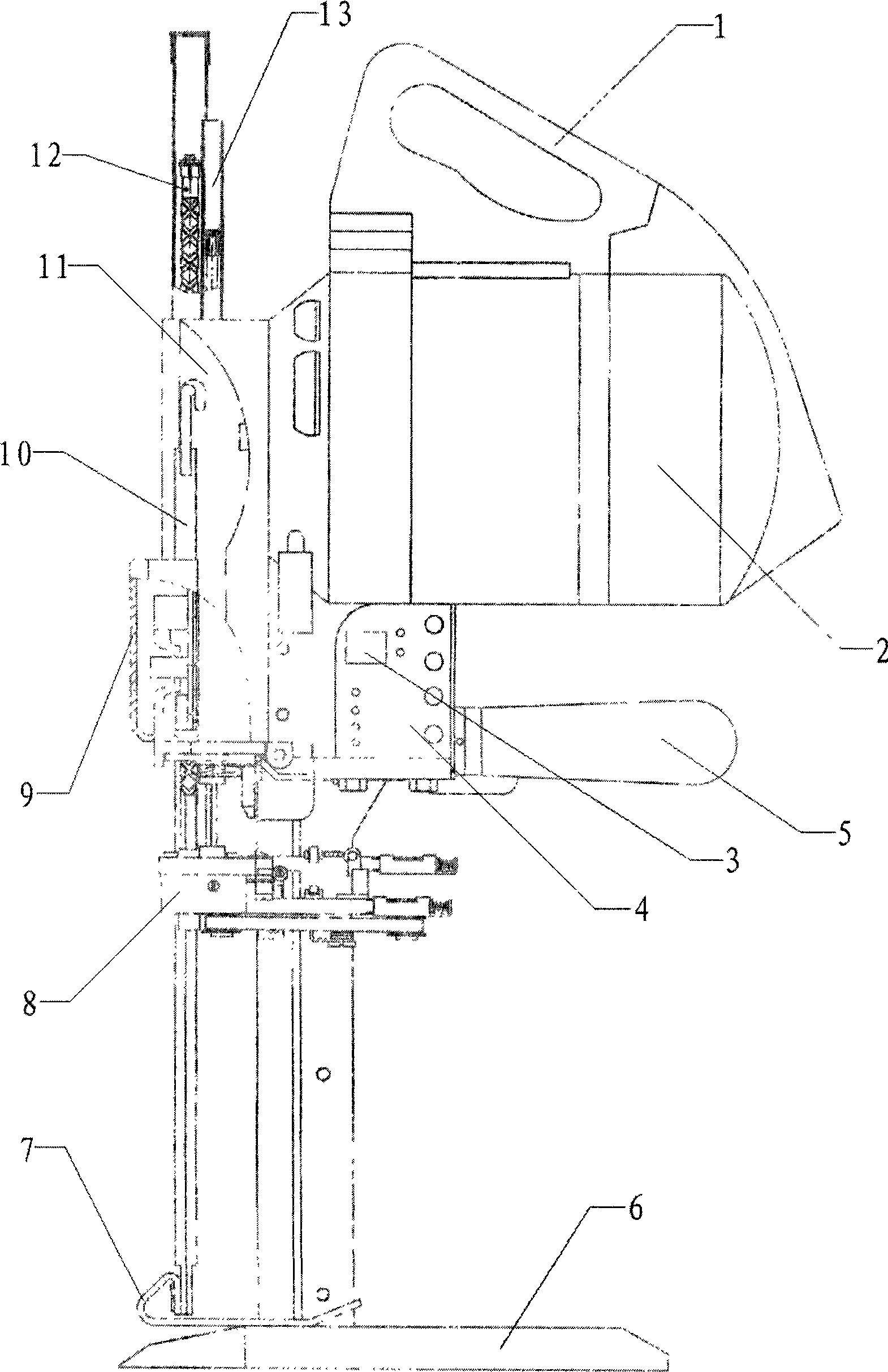

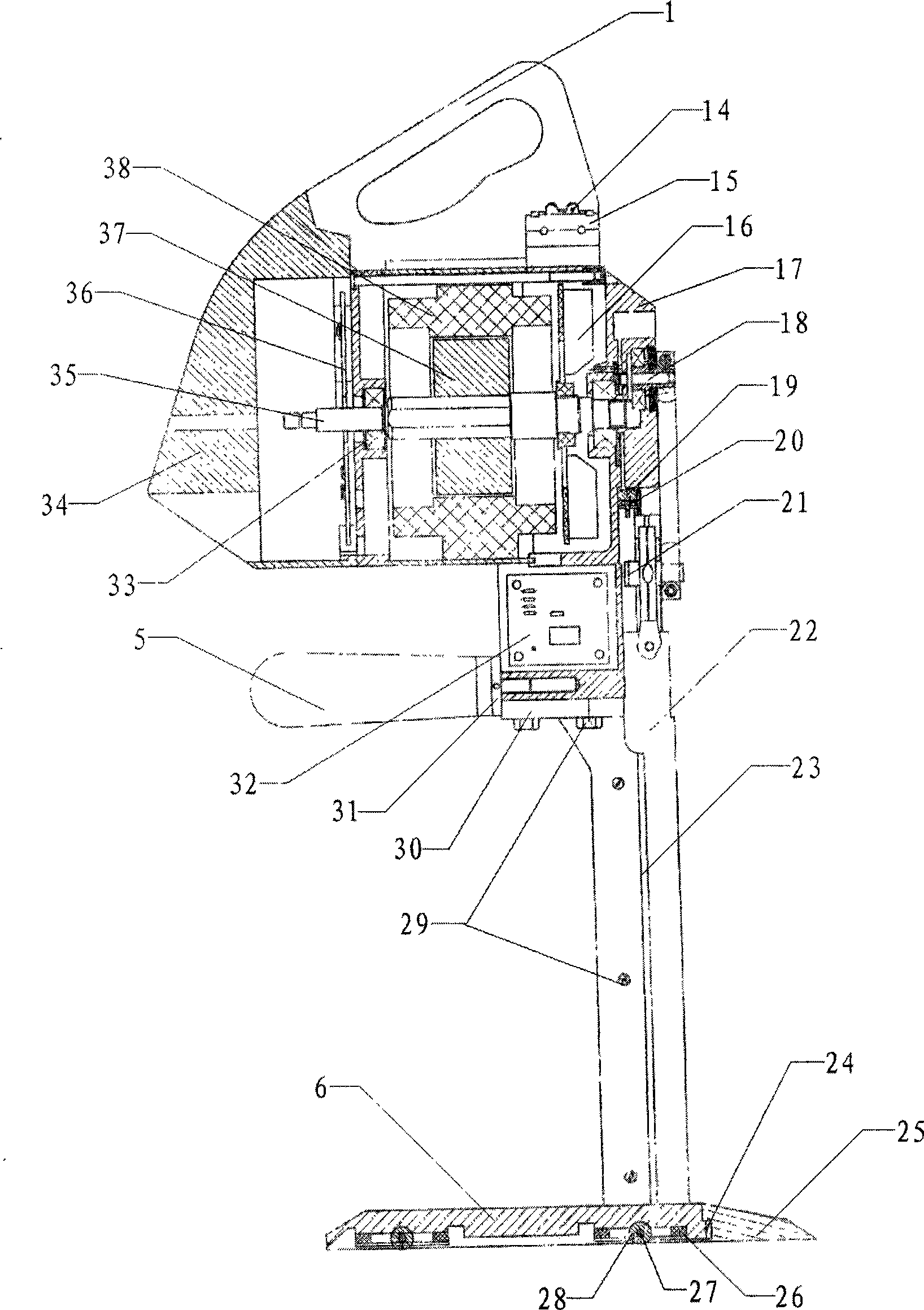

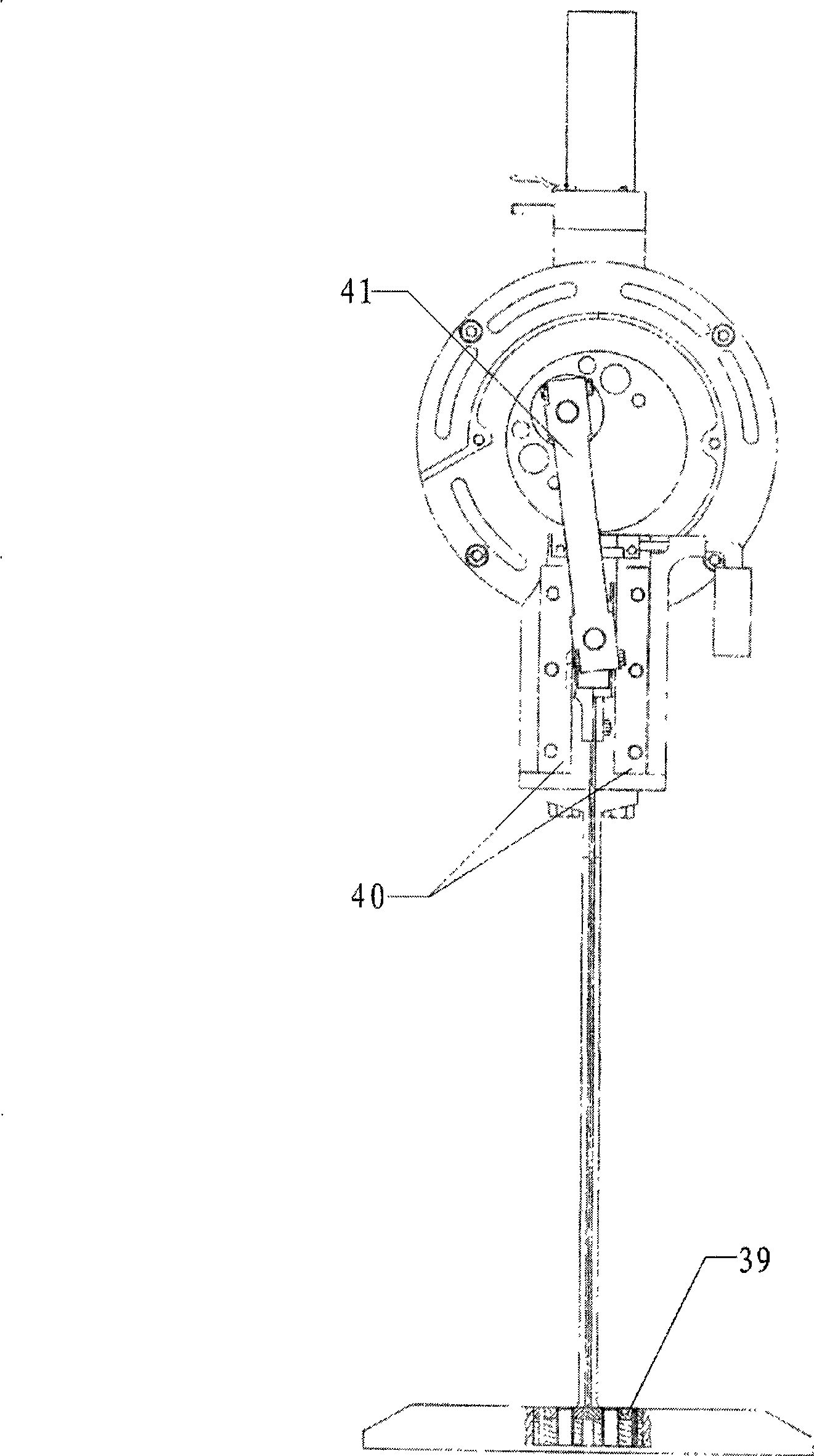

[0013] Such as figure 1 As shown, the numerical control electric cutting machine described in the embodiment of the present invention includes a handle 1, a drive mechanism 2, a chassis 6, and an adjustment mechanism 12. The lower part of the handle 1 is a drive mechanism 2, and the drive mechanism 2 adopts an AC permanent magnet synchronous motor. The bottom of the driving mechanism 2 is provided with a control panel 4 with an indicator screen 3, which can adjust the speed and gear position. The inner side of the control panel 4 is connected to the lower handle 5, and the driving mechanism 2 and the control panel 4 are connected as one and installed On the adjustment mechanism 12 with the guide rod, one side of the adjustment mechanism 12 is provided with a guide column 13 connected with the drive mechanism 2; Vertically, presser foot bar 10, cam cover 9 and abrasive belt wheel grinding assembly 8 are successively arranged from top to bottom. The bottom of the whole device is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com