Comprehensive damping method for mixed explosion of hard rock tunnel closely attaching to existing underground building

A technology with existing structures and close to the ground, applied in blasting and other directions, can solve the problems of inaccessibility, long cycle time, difficult practical application, etc., and achieve the effect of reducing damage, reducing damage and avoiding damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

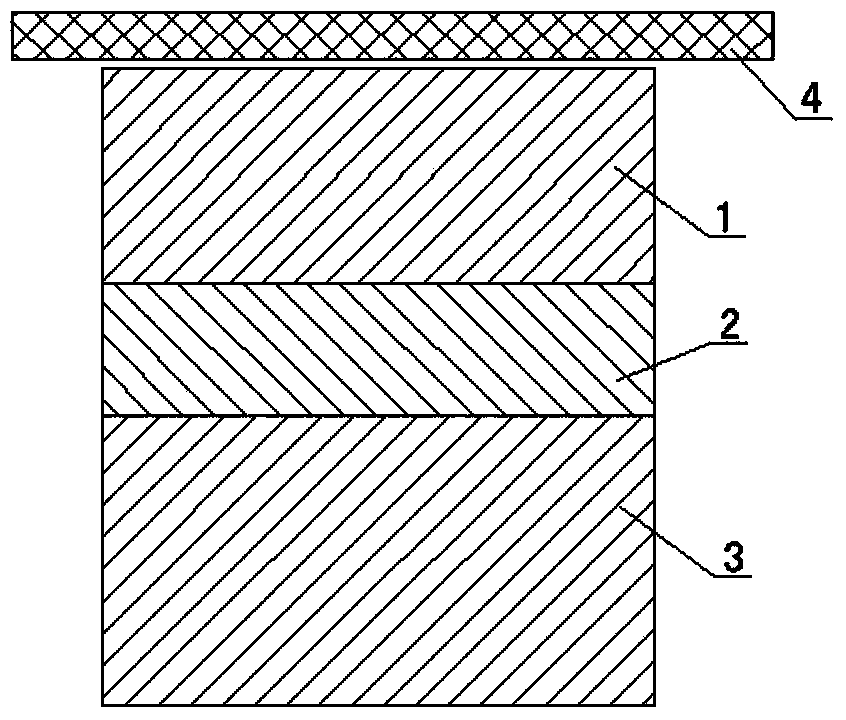

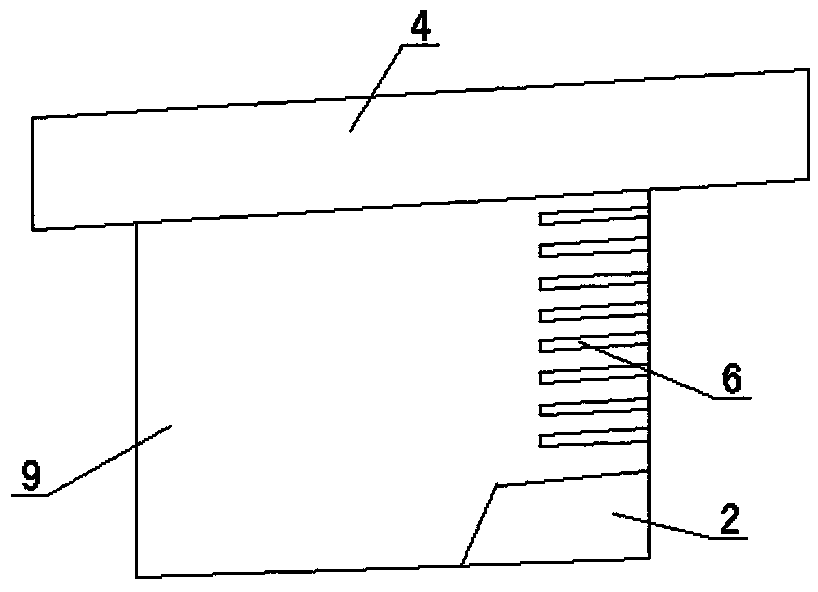

[0036] see figure 1 , figure 2 , image 3 and Figure 4 In this embodiment, the division area of the mixed blasting of the hard rock tunnel close to the existing underground structure is: below the existing structure floor 4 of the existing structure, the blasting operation surface is divided into areas in sequence in the direction of depth: the metal expansion blasting area 1. Emulsion explosive cutting area 2 and emulsion explosive blasting area 3.

[0037] Among them, the metal expansion blasting area 1 is within the depth range of 3m below the existing structural bottom plate 4; the emulsion explosive cutting area 2 is within the depth range of 1m below the metal expansion blasting area 1; the emulsion explosive blasting Zone 3 is within the depth range of 4m below the emulsion explosive cut zone 2.

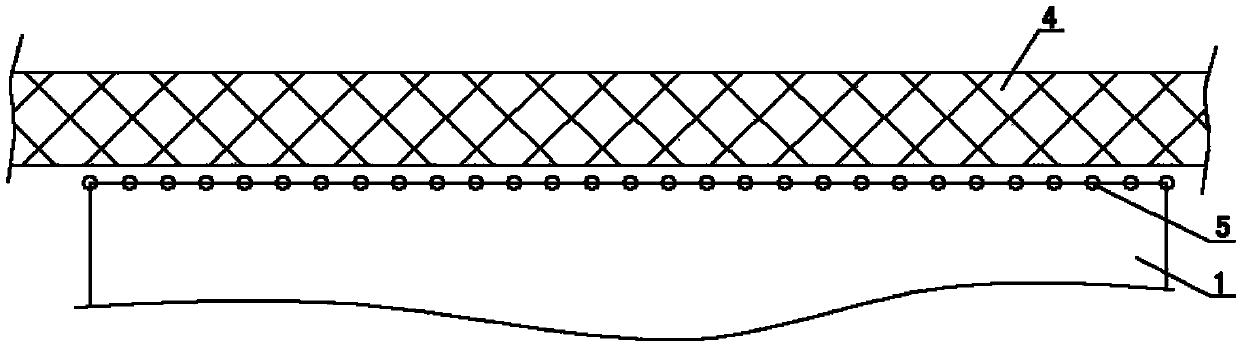

[0038] figure 2 As shown, in this embodiment, a row of vibration isolation holes 5 parallel to the existing structure bottom plate 4 is formed at a position 150 mm b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com