Wall protecting device and hole-wall pressure testing method

A hole wall and pressure technology, which is applied in the field of wall protection device and hole wall pressure test, can solve the problem that the pressure distribution of the blast hole cannot be monitored in real time, and achieve the effect of reducing the damage of the reserved rock mass and reducing the blasting vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

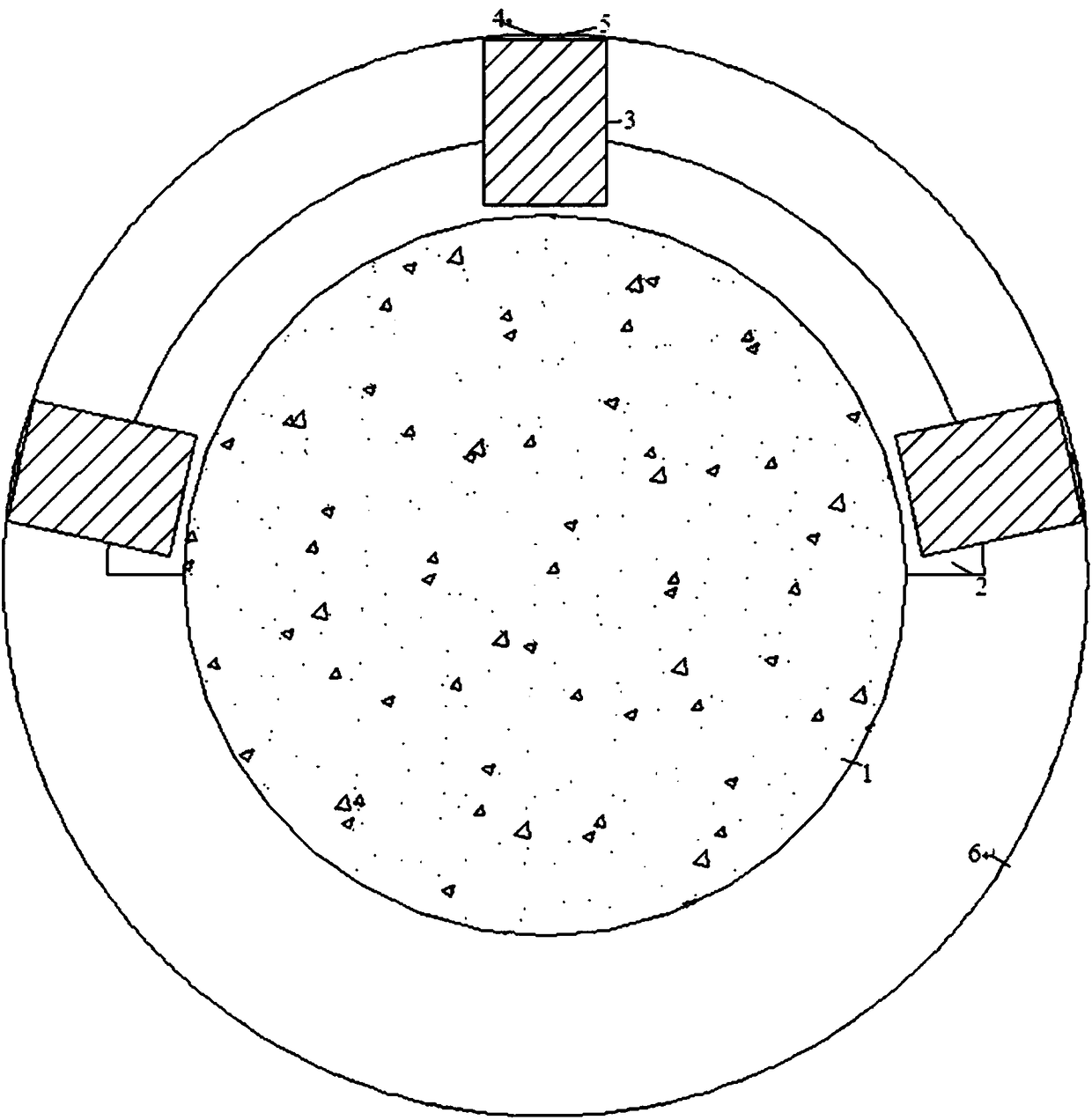

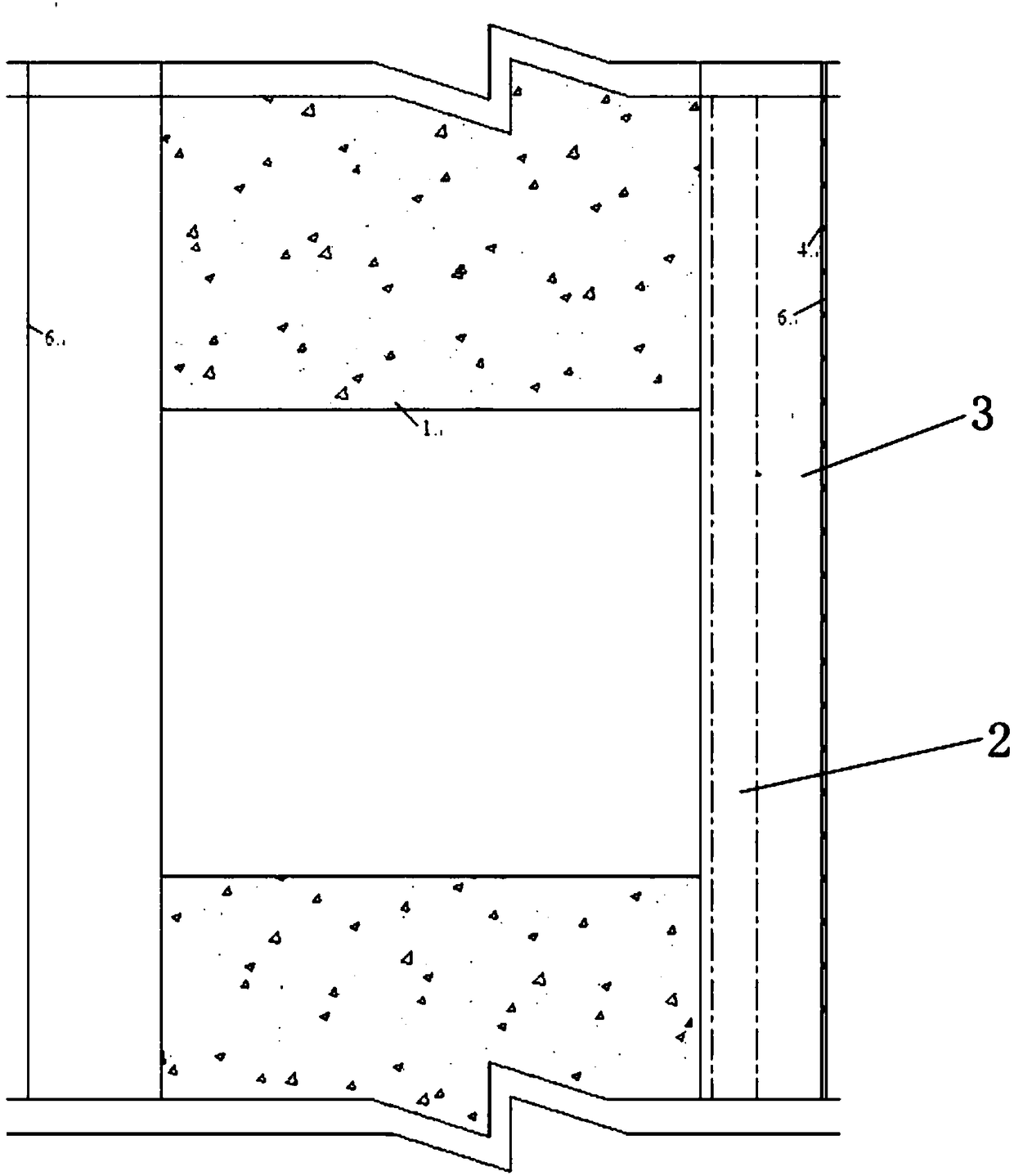

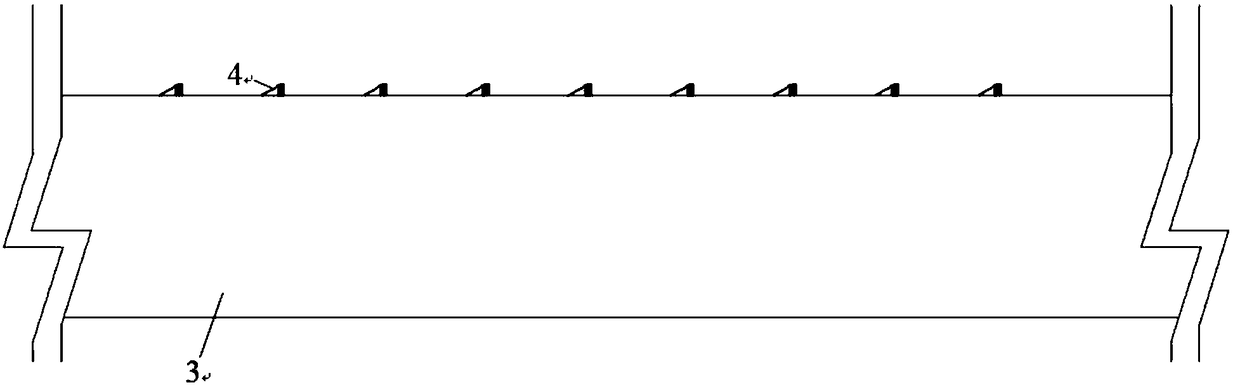

[0040] Such as figure 1 As shown, the wall protection device involved in this scheme includes energy-gathering wall protection half-circle sleeves, strain gauge drawers and dynamic stress sensors.

[0041] The half-circle sleeve of the energy-gathering wall is installed in the blast hole, which is mainly used to shift the energy generated during the explosive blasting toward the pre-excavated rock mass, play the role of energy-gathering blasting, and play a role in buffering the detonation wave directly to the reserved rock mass. The direct action of the body reduces the detonation gas wedged into the primary and secondary cracks of the hole wall, and crushes and destroys the reserved rock mass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com