Side slope excavation smooth-surface blasting-method construction method

A technology of smooth blasting and construction method, applied in the field of blasting, can solve the problems of large damage to the retained rock mass, inability to carry out high slope trimming, poor slope forming quality, etc., so as to improve the quality and progress of the project and reduce the harmful effects of blasting. , reduce the effect of over-digging and under-digging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

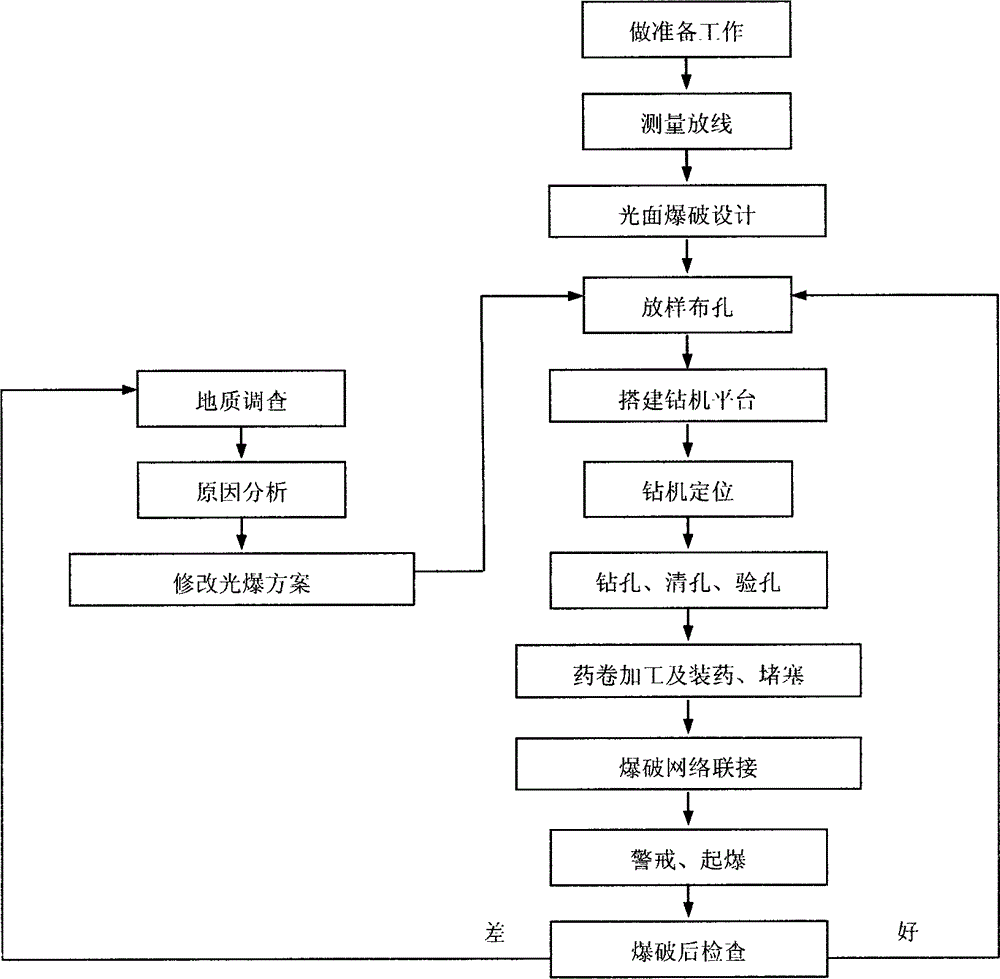

[0040] The present invention is described in further detail now in conjunction with accompanying drawing. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

[0041] Such as figure 1 The smooth surface blasting construction method for slope excavation shown includes:

[0042] (1) Study the design drawings and geological information, and clean up the slope top and uphill road;

[0043] (2) Measure the steps of setting out;

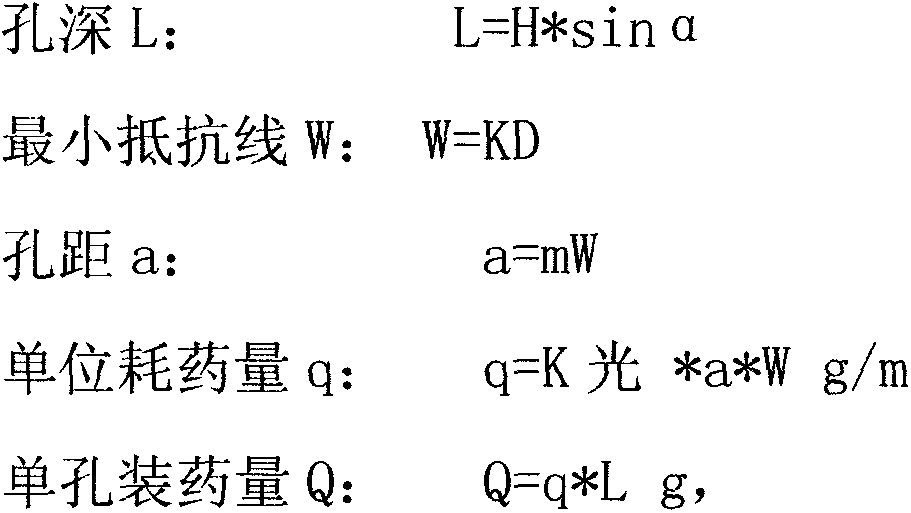

[0044] (3) Steps of smooth blasting parameter design;

[0045] (4) The step of setting out the holes;

[0046] (5) Steps of building the drilling rig platform and positioning the drilling rig platform;

[0047] (6) The steps of drilling, clearing and inspecting holes;

[0048] (7) Steps of drug coil processing, charging, and plugging the top of the hole;

[0049] (8) The steps of detonatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com