Horizontal joint fissure tunnel-smooth-excavation blasting method

A horizontal joint, smooth blasting technology, applied in blasting and other directions, can solve the problems of low blasting energy utilization rate, poor tunnel smooth blasting effect, and low blasting footage, so as to improve blasting effect, energy utilization rate and blasting. The effect of driving footage and improving the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments, and the content of the present invention is not limited to the following embodiments.

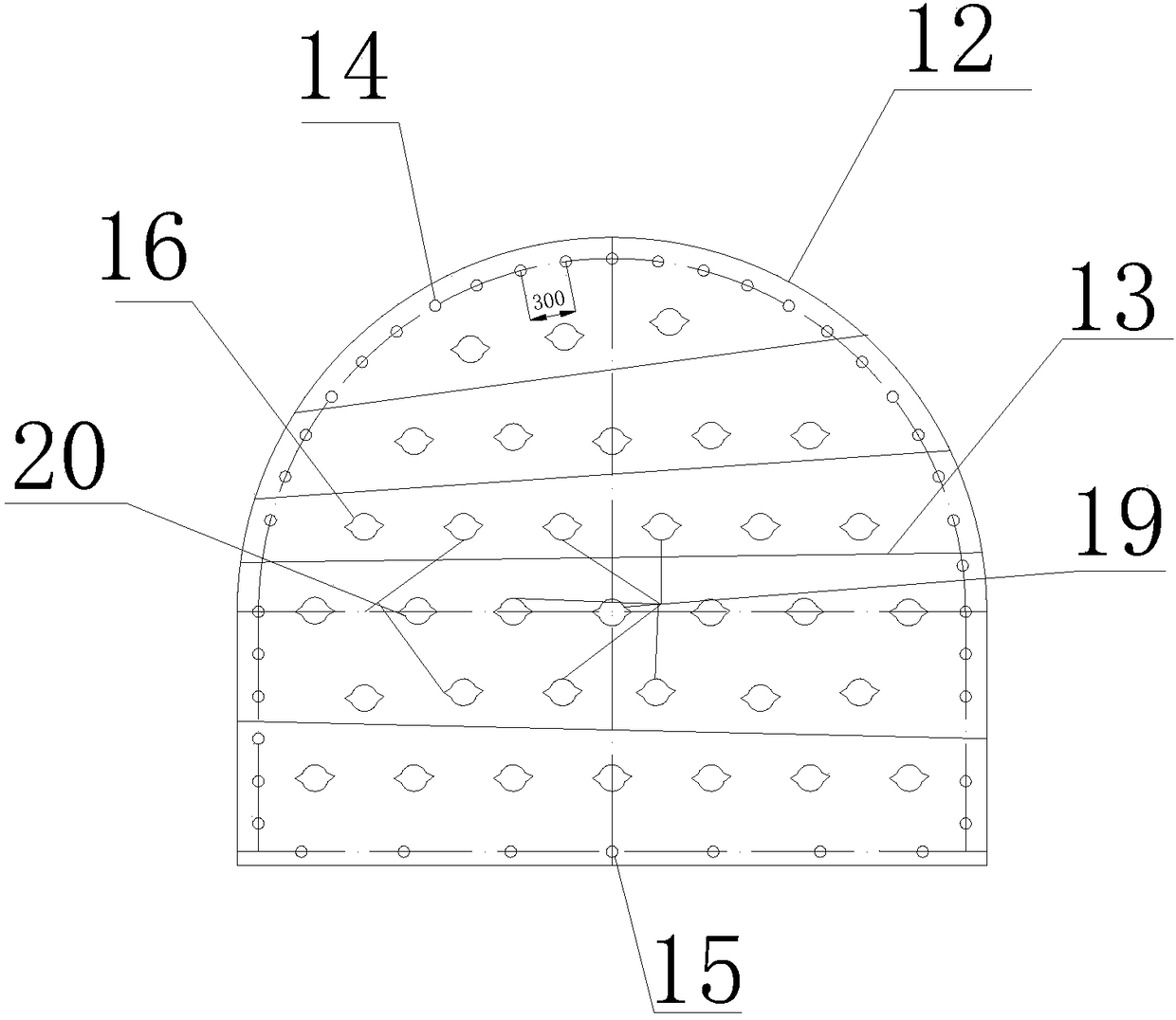

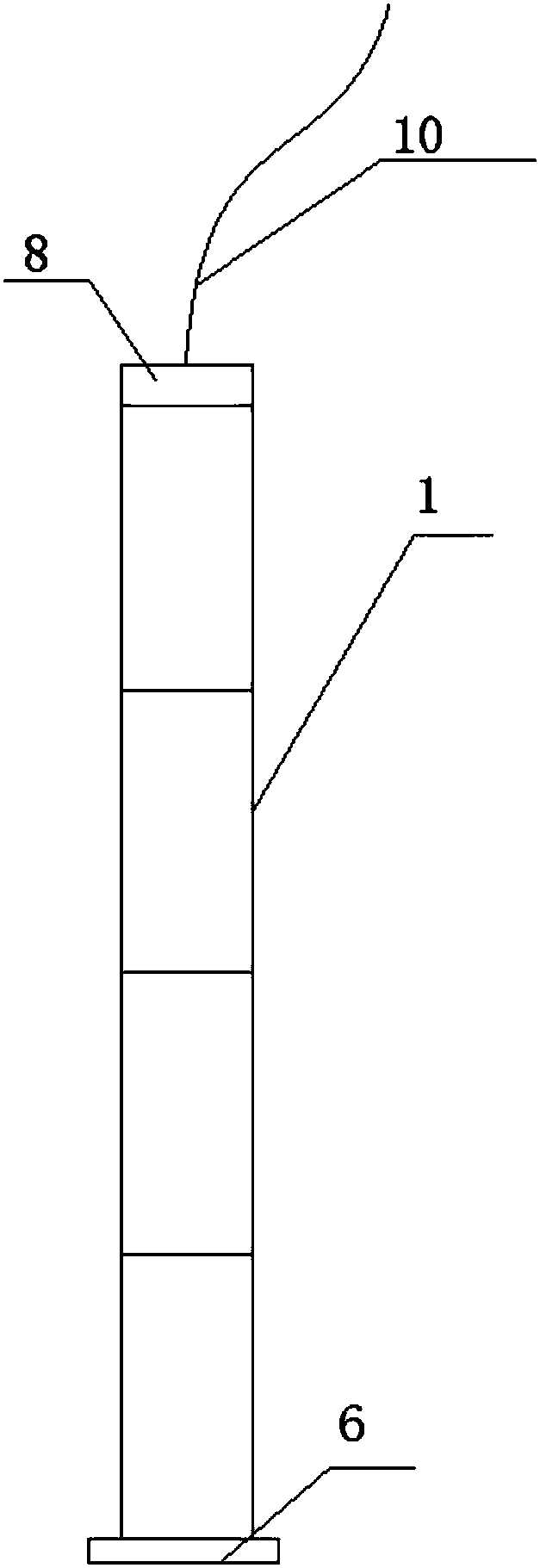

[0035] A blasting method for smooth surface excavation of a tunnel with horizontal joints and fissures, which includes a blasting device controlled by cutting grooves and an axially uncoupled rapid chemical transfer device for smooth blasting;

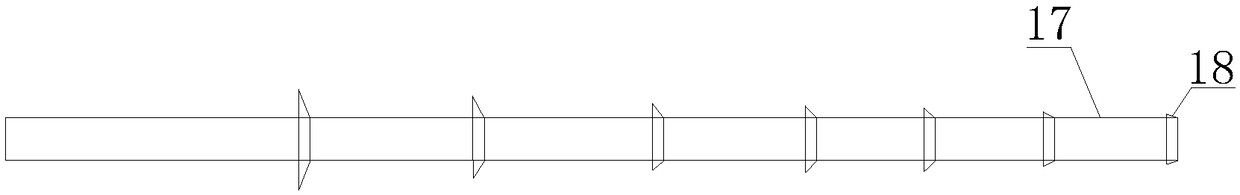

[0036] The grooving control blasting device includes a percussive rock drilling rod 17 and a V-shaped drill bit 18. The percussive rock drilling rod 17 is threadedly connected by a steel pipe, and each section of the steel pipe is equipped with a V of different sizes. Font drill bit 18, the size of described V font drill bit 18 is constantly enlarged, can reduce a grooving occurrence resistance is big, the problems such as poor groove quality, described V font drill bit 18 and steel pipe are connected by thread;

[0037]The s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com