Subway foundation pit blasting method

A technology for subways and foundation pits, applied in blasting and other directions, can solve problems such as earthquake damage, affecting the structural stability of buildings, smooth traffic operation, personnel and property losses, etc., to reduce damage, protect safety, and reduce blasting vibration. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

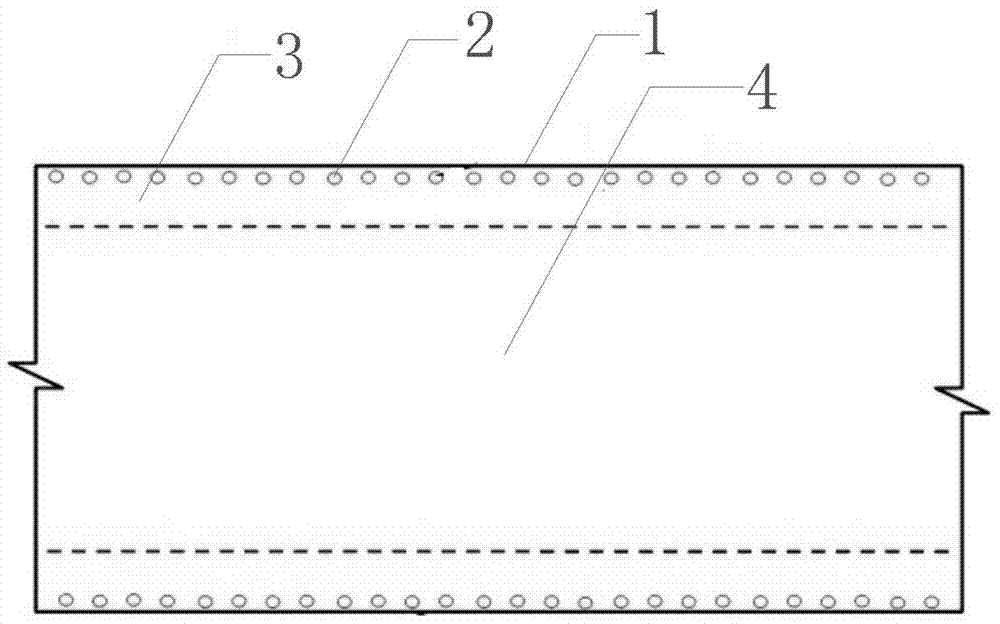

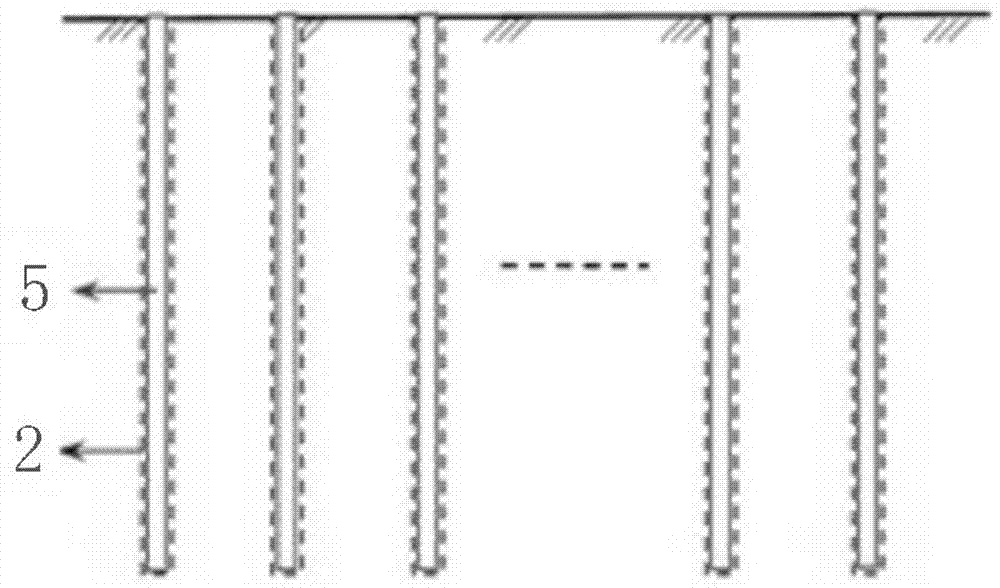

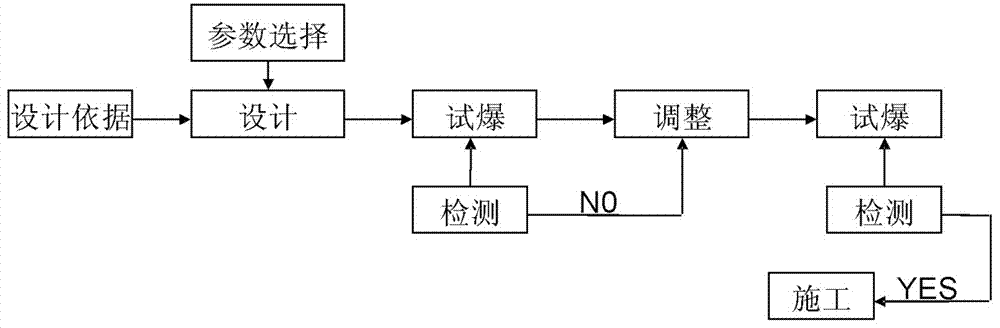

[0021] like figure 1 , 2 As shown, a subway foundation pit blasting method, the shallow hole and small aperture blasting area 3 is set in the foundation pit within 5.0 meters from the underground diaphragm wall sideline 1, and the foundation pit is set outside the 5.0 meter range from the underground diaphragm wall sideline 1 Deep-hole and large-aperture blasting area 4; shock-absorbing holes 2 are set around the foundation pit at a distance of 0.5 meters from the sideline of the underground diaphragm wall, and PVC pipes 5 are arranged in the shock-absorbing holes. One row or two rows or more than two rows can be arranged according to actual needs Vibration hole.

[0022] In this embodiment, the aperture diameter of the shock absorbing hole 2 is 11.5 cm, the hole distance is 50 cm, the hole depth is 21 m, the diameter of the PVC pipe 5 is 11 cm, the length of the PVC pipe 5 is equal to the depth of the shock absorbing hole 2, and the PVC pipe 5 is two The ends are sealed. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com