Method for processing panel into protuberant drum wall-thickening part by utilizing stamping process

A technology for sheet metal processing and workpiece, applied in the field of metal parts processing technology, to achieve the effect of improving service life and ensuring strength requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

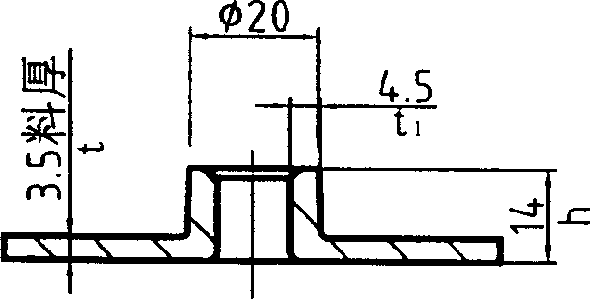

[0014] according to figure 1 As shown, the finished part is a chassis with a wall thickness of 3.5mm (the following measurement units are mm), the height of the boss is 14, the diameter of the boss is 20, and the wall thickness of the boss is 4.5. The process of the present invention produces the above-mentioned size parts, and the steps are as follows:

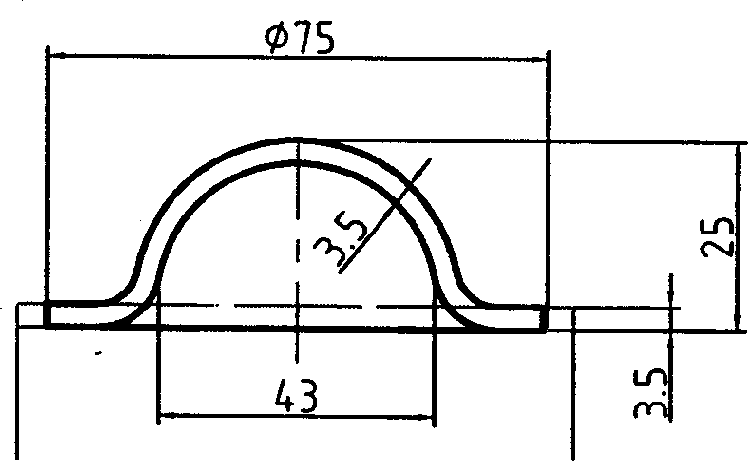

[0015] 1. Preforming: The workpiece plate is preformed into a convex shape by stamping, so that the difference volume is equal to the convex part, the height of the convex part is 26, the diameter is approximately hemisphere with a diameter of φ50, and the thickness remains unchanged;

[0016] 2. Stiff shape: the working diameter of the die is φ40, the mouth fillet is R8, the punch is φ30 and the height is 22. There is also a punching die φ6.8 inside the end to the fillet R7, and the hole punched out in the center of the workpiece is the subsequent positioning And the diameter of the pre-set hole.

[0017] Die work...

Embodiment 2

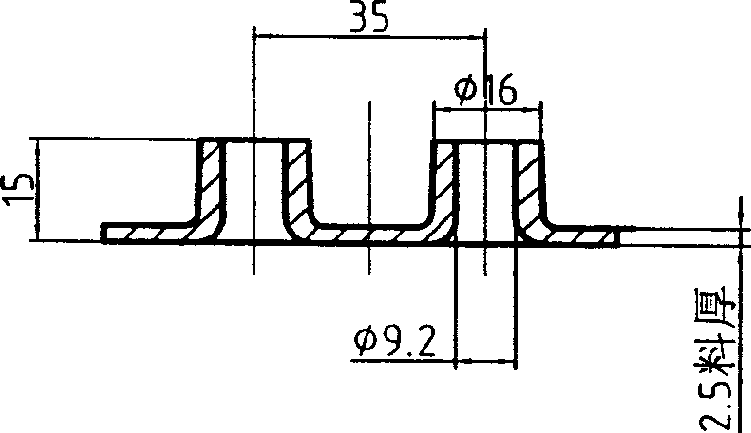

[0021] according to figure 2 As shown, the finished part is a chassis with a wall thickness of 2.5mm (the following measurement units are millimeters mm), with two bosses, the height of the boss is 15, the diameter of the boss is 16, the inner diameter is 9.2, and the center distance of the boss is 35 . The process of the present invention produces the above-mentioned size parts, and the steps are as follows:

[0022] 1. Preforming: Different from the general literature records, firstly, the punch and the sheet material form a 45° direction, and the two punches form a 90° angle between the same side of the sheet material, and the workpiece sheet is preformed by stamping. Cone, straight wall spacing 4. This scheme causes compressive stress to be first generated at the part of the workpiece that is easy to break, and the local material is replenished enough so that it will not crack when pulled. The flat center distance between the two punches of the second set of molds is s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com