Gob-side entry three-dimensional reinforcement filled wall structure and filling method thereof

A technology for filling walls and retaining roadways, which is applied in the direction of filling, earthwork drilling and mining, safety devices, etc., and can solve problems such as polluting the atmospheric environment, prone to landslides, and occupying land

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

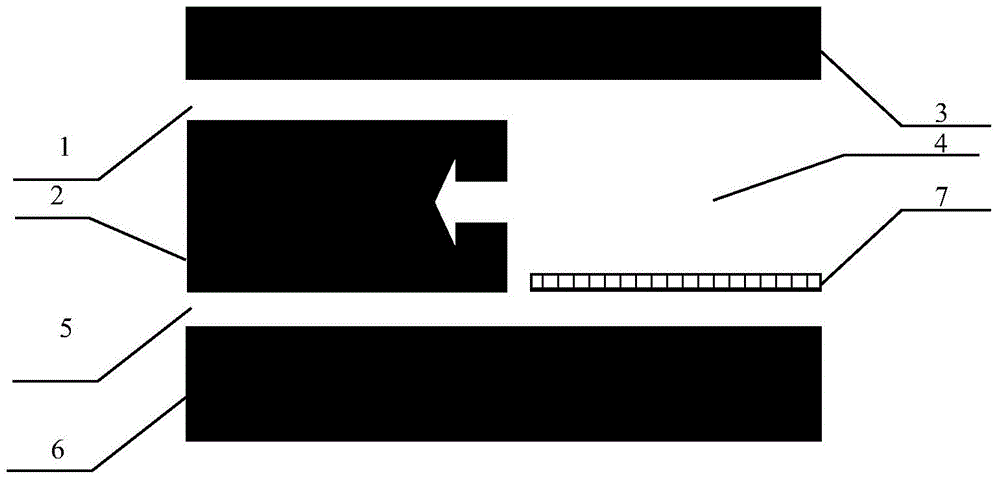

[0058] like figure 1 As shown, it is a schematic diagram of the planar structure of each part of the underground, including the upper working face coal body 3, the lower working face coal body 6, the working face coal body 2, the air return lane 1, the transportation lane 5, and the goaf 4; The three-dimensional reinforced filling wall structure 7 for gob-side entry retention is arranged in the goaf 4 near the transport entryway 5 .

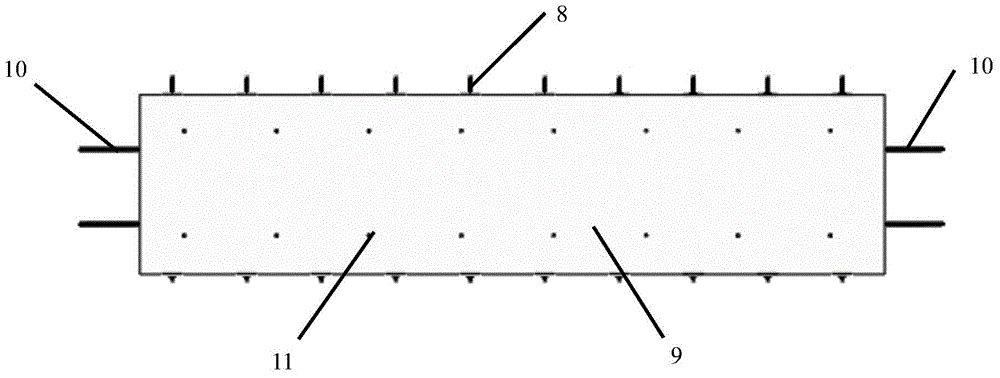

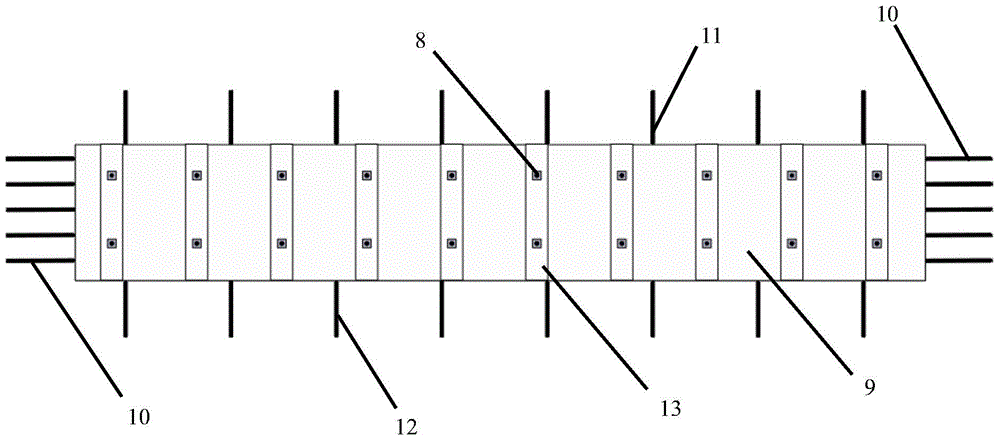

[0059] like Figure 2 ~ Figure 4 As shown, the three-dimensional reinforced filling wall structure 7 of the gob-side entry retention described in the present invention includes:

[0060] The wall body 9 is cuboid, and its height is the same as that of the roadway;

[0061] A plurality of roof reinforcement bolts 11, a part of each roof reinforcement bolt 11 is buried in the wall body 9, and a part is buried in the roadway roof;

[0062] A plurality of floor reinforcing anchors 12, a part of each of the floor strengthening anchors 12 is embedde...

Embodiment 2

[0067] like Figure 2 ~ Figure 4 As shown, the three-dimensional reinforced filling wall structure 7 of the gob-side entry retention described in the present invention includes:

[0068] The wall body 9 is cuboid, and its height is the same as that of the roadway;

[0069] A plurality of roof reinforcement bolts 11, a part of each roof reinforcement bolt 11 is buried in the wall body 9, and a part is buried in the roadway roof;

[0070] A plurality of floor reinforcing anchors 12, a part of each of the floor strengthening anchors 12 is embedded in the wall body 9, and a part is embedded in the roadway floor;

[0071] A plurality of running rebars 10, a part of each running rebar 10 is embedded in the wall body 9, and a part is exposed from the left and right sides of the wall body 9;

[0072] A plurality of inclined wall anchor rods 8, each of the inclined wall anchor rods 8 completely penetrates the wall body 9, and both ends are exposed from the front and rear sides of the...

Embodiment 3

[0102] Each of the roof reinforcement bolts 11 is 1800mm long, and the length of the part embedded in the roadway roof is 700mm. Two adjacent roof reinforcement bolts 11 in the same row and two rows of roof reinforcement bolts The distance between 11 is all between 900mm.

[0103] The length of each floor reinforcement bolt 12 is 2200mm, and the length of the part embedded in the roadway floor is 1300mm, and the distance between two adjacent floor reinforcement bolts 12 in the same row is 1500mm.

[0104] The distance between 10 of the two said direction rebars in the same column and the distance between the two columns is 900mm.

[0105] The distance between two adjacent inclined wall anchor rods 8 in the same row or column is 1500 mm; the exposed parts at both ends are 30 mm long.

[0106] Before fixing the channel steel 13 by using a tray and a nut to cooperate with the threaded structure, apply an initial pre-tightening force between 50KN to the inclined wall anchor rod 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com