Interior decorative composite board for automobile roof panel

A composite sheet and roof technology, which is applied in the field of automotive interior decoration, can solve problems such as easy delamination, no impact resistance, and difficult to decompose, and achieve good air permeability, high strength, and environmental protection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

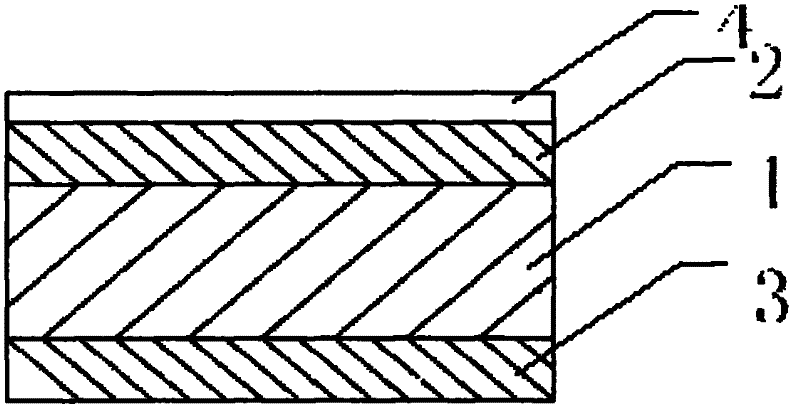

[0032] A kind of automotive headliner interior trim composite plate, comprising middle non-woven layer 1, upper non-woven fabric layer 2 compounded with the upper surface of said middle non-woven layer 1, and upper non-woven fabric layer 2 compounded with the lower surface of said middle non-woven layer 1 For the lower non-woven fabric layer 3, the weight percentages of materials used in the middle non-woven layer 1 are: hemp fiber accounts for 48%, and polylactic acid fiber accounts for 52%.

[0033] In order to improve environmental performance, both the upper non-woven layer 2 and the lower non-woven layer 3 use chemical fibers. In this embodiment, the upper non-woven layer uses nylon fibers, and the lower non-woven layer uses polyvinyl chloride fibers. fiber.

[0034] In order to increase the aesthetics, a layer of adhesive film layer 4 is compounded on the outer surface of the upper non-woven layer 2, see figure 1 , under the premise of ensuring the aesthetics, the speci...

Embodiment 2

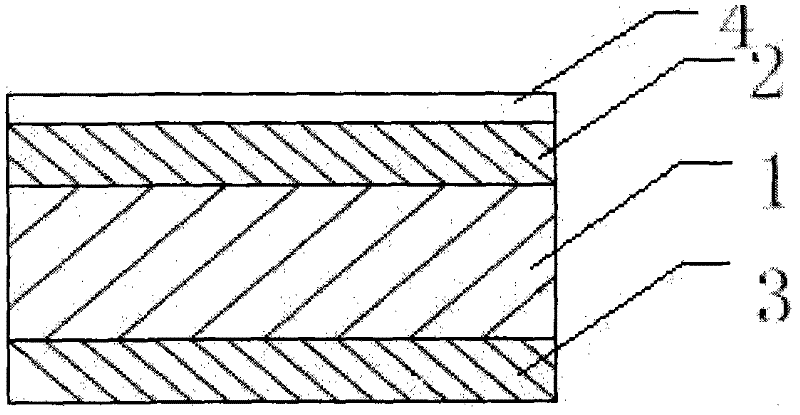

[0038] A kind of automotive headliner interior trim composite plate, comprising middle non-woven layer 1, upper non-woven fabric layer 2 compounded with the upper surface of said middle non-woven layer 1, and upper non-woven fabric layer 2 compounded with the lower surface of said middle non-woven layer 1 For the lower non-woven layer 3, the weight percentages of materials used in the middle non-woven layer 1 are: hemp fiber accounts for 80%, and polypropylene fiber accounts for 20%.

[0039] In order to improve environmental performance, both the upper non-woven layer 2 and the lower non-woven layer 3 are made of polypropylene fiber.

[0040] In order to increase the aesthetics, a layer of adhesive film layer 4 is compounded on the outer surface of the upper non-woven layer 2, see figure 1 , under the premise of ensuring the aesthetics, the specific material of the film layer 4 is not strictly limited.

[0041] In order to make each layer meet the strength requirements while...

Embodiment 3

[0044] A kind of automotive headliner interior trim composite plate, comprising middle non-woven layer 1, upper non-woven fabric layer 2 compounded with the upper surface of said middle non-woven layer 1, and upper non-woven fabric layer 2 compounded with the lower surface of said middle non-woven layer 1 The lower non-woven fabric layer 3, the weight percentage of the material used in the middle non-woven layer 1 is: hemp fiber accounts for 60%, low-melting point fiber accounts for 20%, and the content of other fibers is 20%, and the low-melting point fiber is polypropylene fiber and polylactic acid fiber, wherein the weight percentage of the polylactic acid fiber is 80%.

[0045] In order to improve environmental protection performance, both the upper non-woven layer 2 and the lower non-woven layer 3 use polychloride fibers.

[0046] In order to increase the aesthetics, a layer of adhesive film layer 4 is compounded on the outer surface of the upper non-woven layer 2, see f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com