Direct dry-film adhering process for hollowed-out region of hollowed-out flexible circuit board

A flexible circuit board and dry film sticking technology, which is applied in the secondary treatment of printed circuits, the removal of conductive materials by chemical/electrolytic methods, and the application of non-metallic protective layers. pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

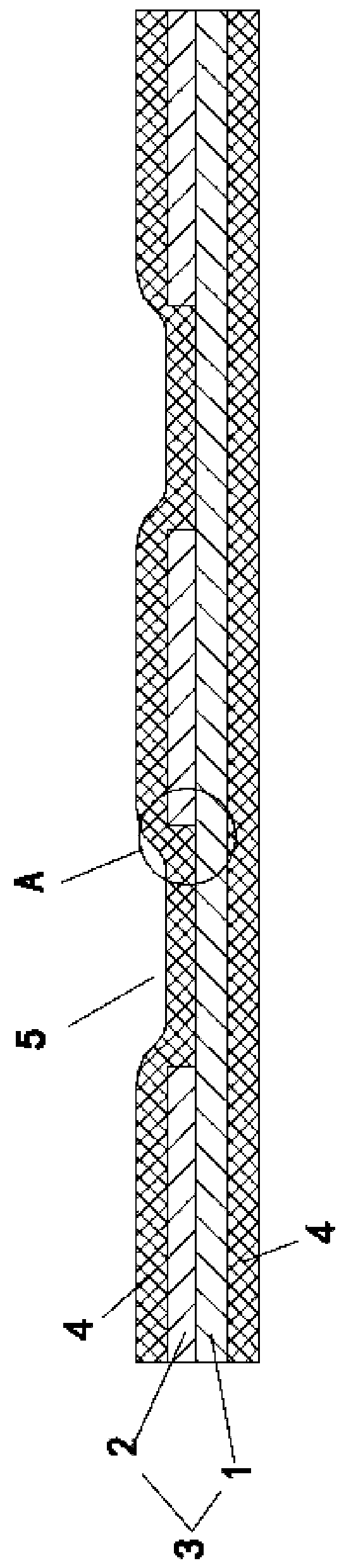

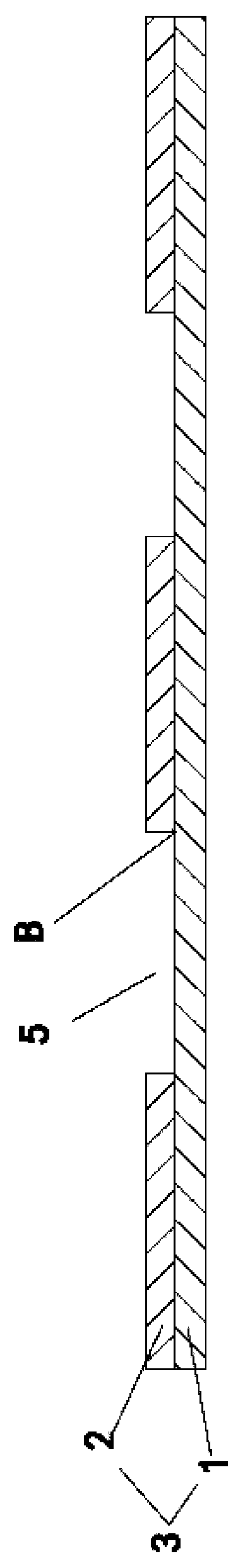

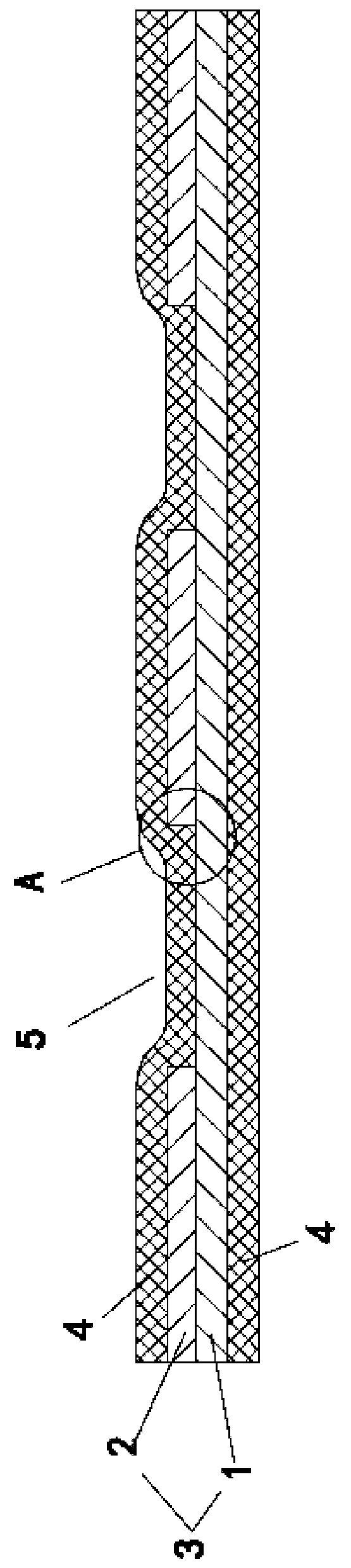

[0020] In order to illustrate the technical solution of the present invention more clearly, the accompanying drawings that need to be used in the description will be briefly introduced below. Obviously, the accompanying drawings in the following description are only some embodiments of the present invention. As far as people are concerned, other embodiments can also be obtained according to these drawings on the premise of not paying creative work.

[0021] The present invention comprises the steps:

[0022] First, use a CNC drilling machine to drill out the pre-set positioning holes on the cover film 2 and pure copper foil 1, and open the window and hollow out the cover film according to the required position of the pad 5, and then according to the position on the cover film 2 and copper foil 1, The positioning holes are aligned and bonded with an alignment jig, and then laminated and cured to obtain a semi-finished copper-clad flexible board 3 formed by opening a window at a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com