A kind of production method of unsaturated polyester resin

The technology of a polyester resin and a production method, which is applied in the production field of unsaturated polyester resin, can solve the problems of blocking condensation pipes, increasing the pressure of sewage treatment, increasing the loss of benzoic acid, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0011] Embodiment 1: the production of unsaturated polyester resin (UPR)

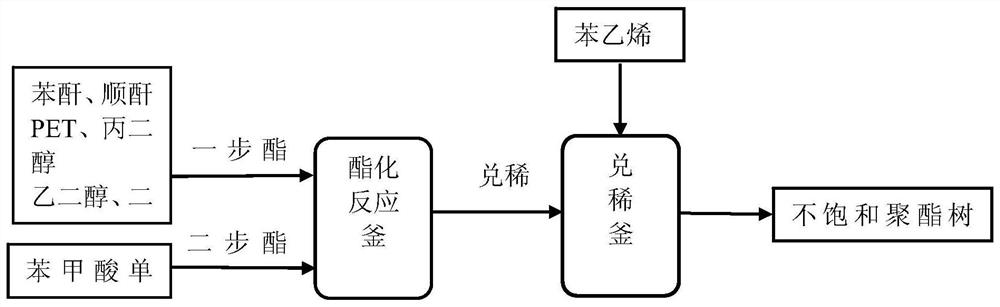

[0012] Unsaturated polyester resin is made of propylene glycol, phthalic anhydride, maleic anhydride, etc. according to a certain proportion, through polycondensation reaction at 160-210°C, then add paraffin, styrene and accelerator, etc., and mix at 70-80°C Dissolved to obtain a liquid resin product with a certain viscosity. Specific process such as figure 1 Shown:

[0013] Add materials according to different types of unsaturated polyester resin formulas, first add glycol (propylene glycol, diethylene glycol, ethylene glycol, etc.) In the case of feeding nitrogen, and then gradually adding solid materials (phthalic anhydride, maleic anhydride, PET, etc.), after the feeding of each component is completed, continue to gradually heat for esterification reaction, raise the temperature to 190-200 ° C, and keep warm to a certain extent. Add crude monoesters (accounting for 5%-25% of the amount of diols) ...

Embodiment 2

[0014] Embodiment 2: benzoic esterification process

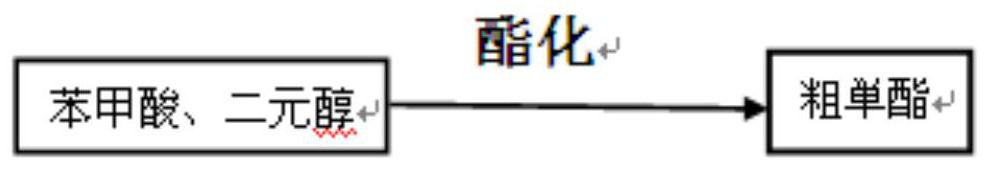

[0015] Benzoic acid monoester is to adopt benzoic acid and dibasic alcohol to make through esterification reaction, and reaction process flow chart is as follows figure 2 Shown:

[0016] Benzoic acid and diols (diethylene glycol, glycerol, ethylene glycol, propylene glycol) are fed into the reaction kettle according to the ratio of 1:1.1, nitrogen deoxidation, and the temperature is slowly raised to about 200 ° C for 4 to 6 hours. Reaction to the end of the reaction (acid value below 50mg.koh / g), to obtain benzoic acid monoester.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com