Magnetic body composition and its preparation method

A composition and magnetic technology, applied in the field of chemistry, can solve the problems that the magnetic performance index cannot meet the needs of engineering and practical applications, the surface of magnetic materials is rough, easy to corrode, etc., and achieves excellent magnetic properties, enhanced stability, Magnetized full effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

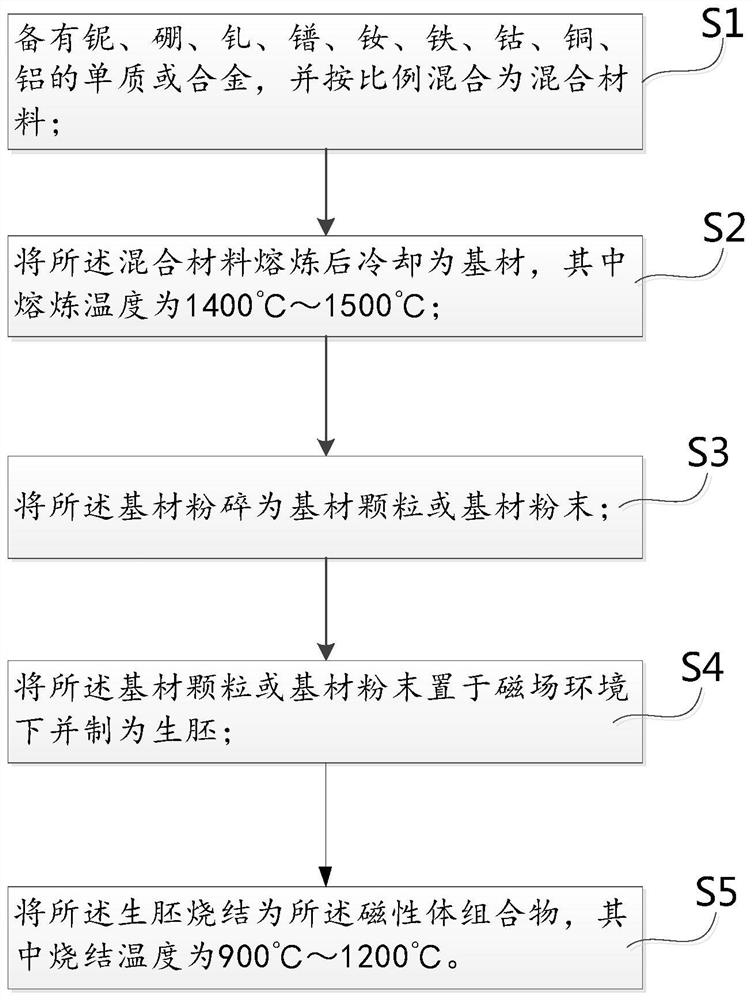

Method used

Image

Examples

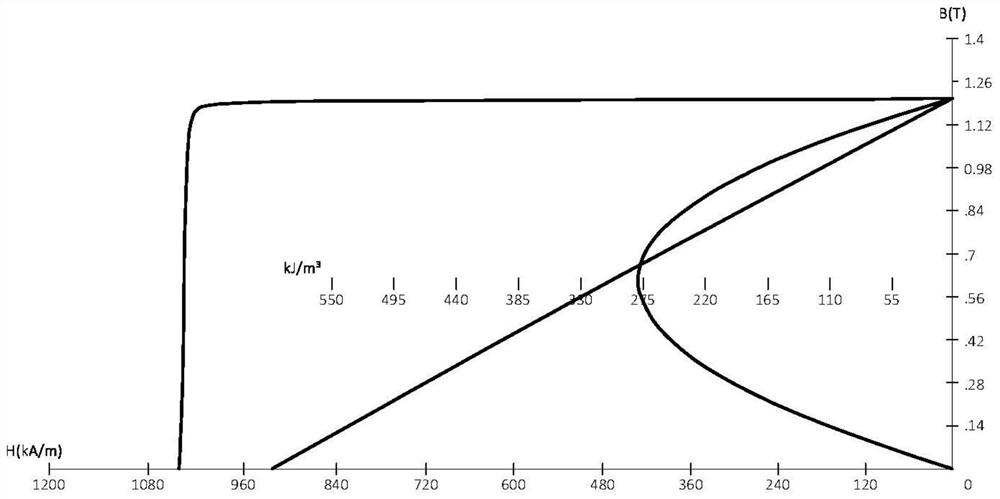

Embodiment 1

[0048] In this embodiment, a magnetic composition 1 is proposed, and the magnetic composition 1 includes the following components:

[0049]

[0050] In other possible implementations, the magnetic composition 1 can also be selected from the following composition ranges:

[0051]

[0052] Specifically, in another embodiment, the magnetic composition 1 can also select the following composition range:

[0053]

[0054]

[0055] More specifically, in another embodiment, the magnetic composition 1 can also choose the following composition range:

[0056]

[0057] In this embodiment, specifically, the niobium and part of the iron are derived from iron-niobium alloy, the boron and part of the iron are derived from iron-boron alloy, the gadolinium and part of the iron are derived from iron-gadolinium alloy, and the praseodymium and neodymium are derived from In praseodymium neodymium alloy. The niobium and iron are preformed into niobium-iron alloy, the boron and iron...

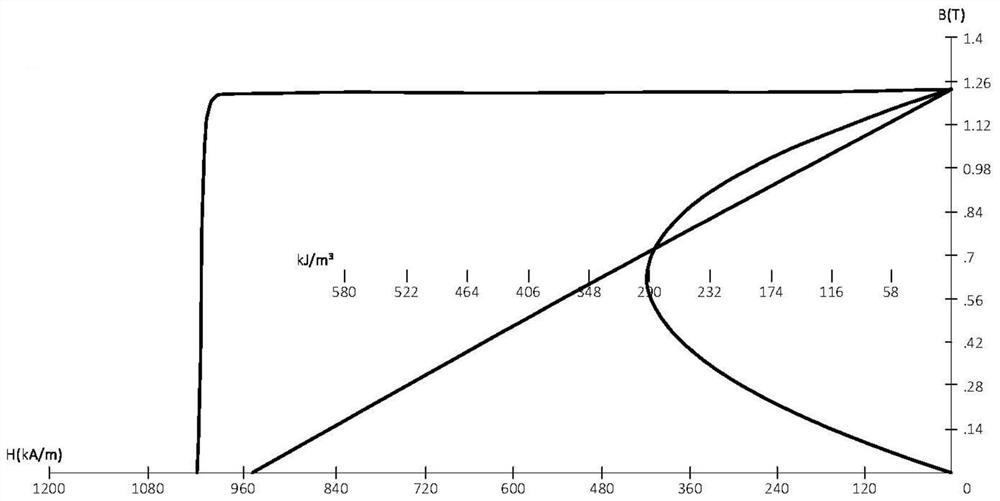

Embodiment 2

[0076] In this embodiment, a magnetic composition 2 is proposed, and the magnetic composition 2 includes the following components:

[0077]

[0078] In this embodiment, the niobium and part of iron are derived from ferro-niobium alloy, the boron and part of iron are derived from iron-boron alloy, the gadolinium and part of iron are derived from iron-gadolinium alloy, and the praseodymium and neodymium are derived from praseodymium Neodymium alloy. Wherein, in the niobium-iron alloy, the proportion of niobium element is 60%-70%. In the boron-iron alloy, the proportion of boron element is 10%-20%. In the gadolinium-iron alloy, the proportion of gadolinium element is 60%-80%. In the praseodymium neodymium alloy, the proportion of praseodymium element is 10%-30%.

[0079] In this embodiment, the preferred solution is:

[0080] In the ferroniobium alloy, the niobium element accounts for 60%;

[0081] In the boron-iron alloy, the boron element accounts for 10%;

[0082] In ...

Embodiment 3

[0094] In this embodiment, a magnetic composition 3 is proposed, and the magnetic composition 3 includes the following components:

[0095]

[0096]

[0097] In this embodiment, the niobium and part of iron are derived from ferro-niobium alloy, the boron and part of iron are derived from iron-boron alloy, the gadolinium and part of iron are derived from iron-gadolinium alloy, and the praseodymium and neodymium are derived from praseodymium Neodymium alloy. Wherein, in the niobium-iron alloy, the proportion of niobium element is 60%-70%. In the boron-iron alloy, the proportion of boron element is 10%-20%. In the gadolinium-iron alloy, the proportion of gadolinium element is 60%-80%. In the praseodymium neodymium alloy, the proportion of praseodymium element is 10%-30%.

[0098] In this embodiment, the preferred solution is:

[0099] In the ferroniobium alloy, the niobium element accounts for 70%;

[0100] In the boron-iron alloy, the proportion of boron element is 20...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com